Thermostatic toilet seat, seating signal collection method and temperature control method

A seat ring and constant temperature technology, applied in the field of toilet cover, can solve the problems of many processes, insufficient surface hardness of the seat ring, weak strength of the bonding part, etc., achieving the effect of simple production process, eliminating the risk of electric shock, and reducing the overall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

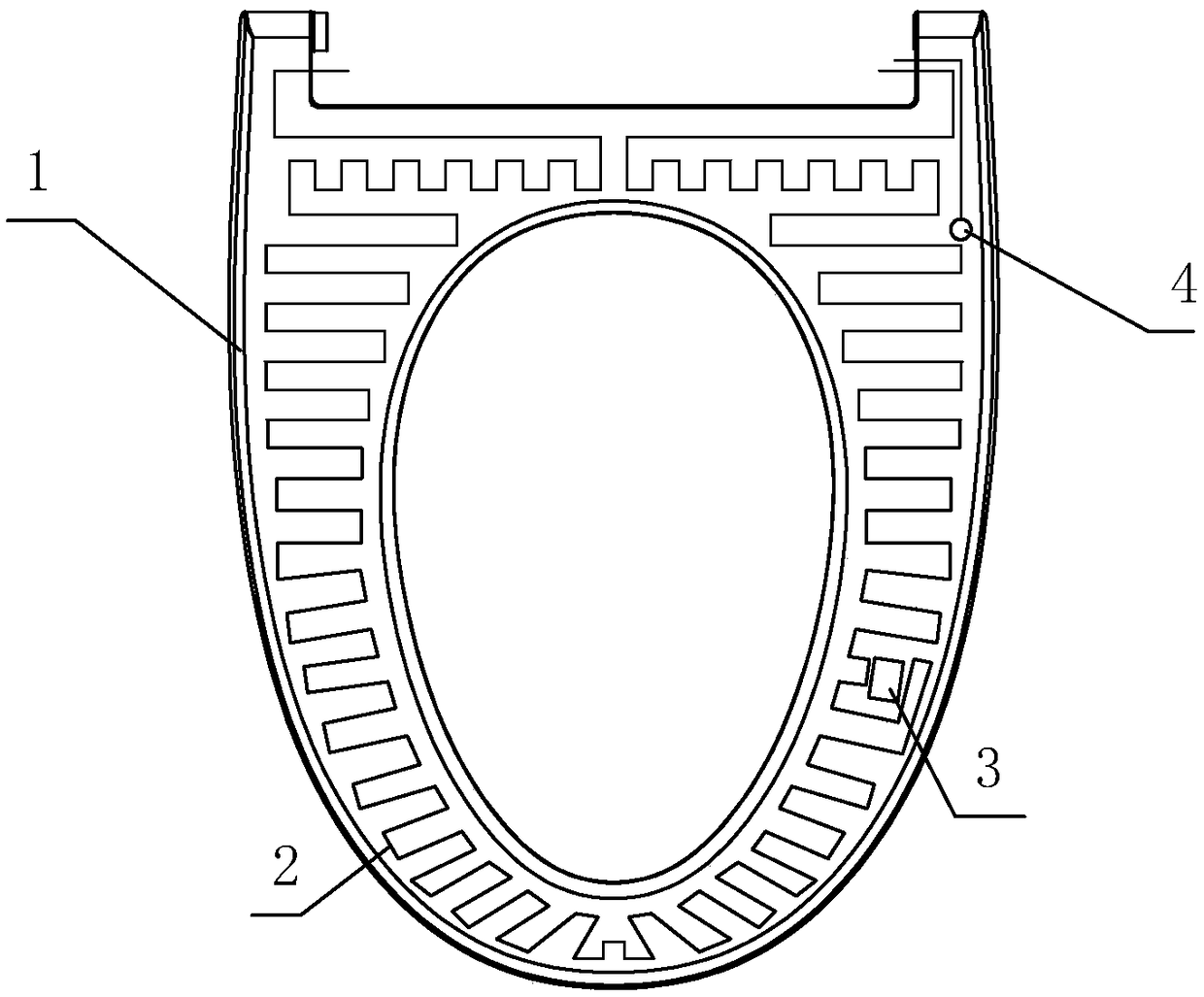

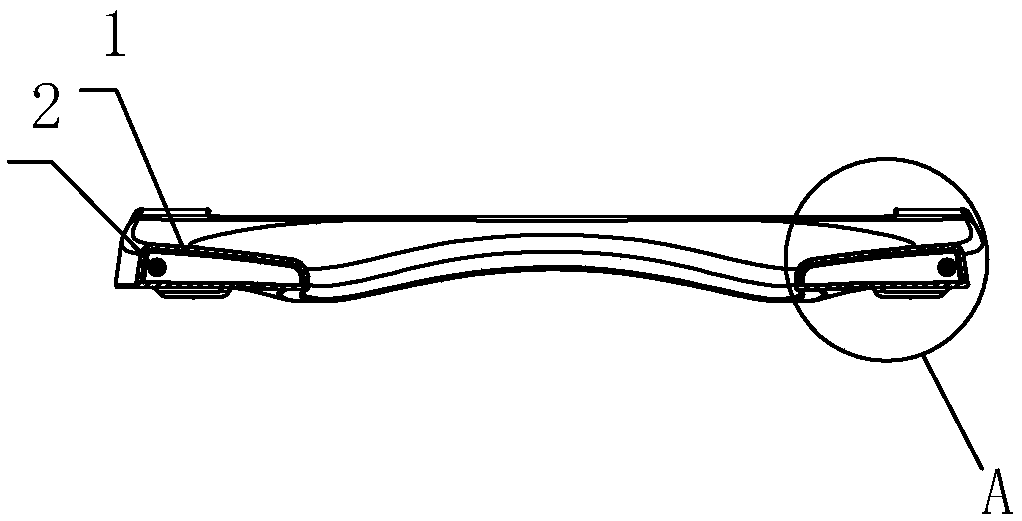

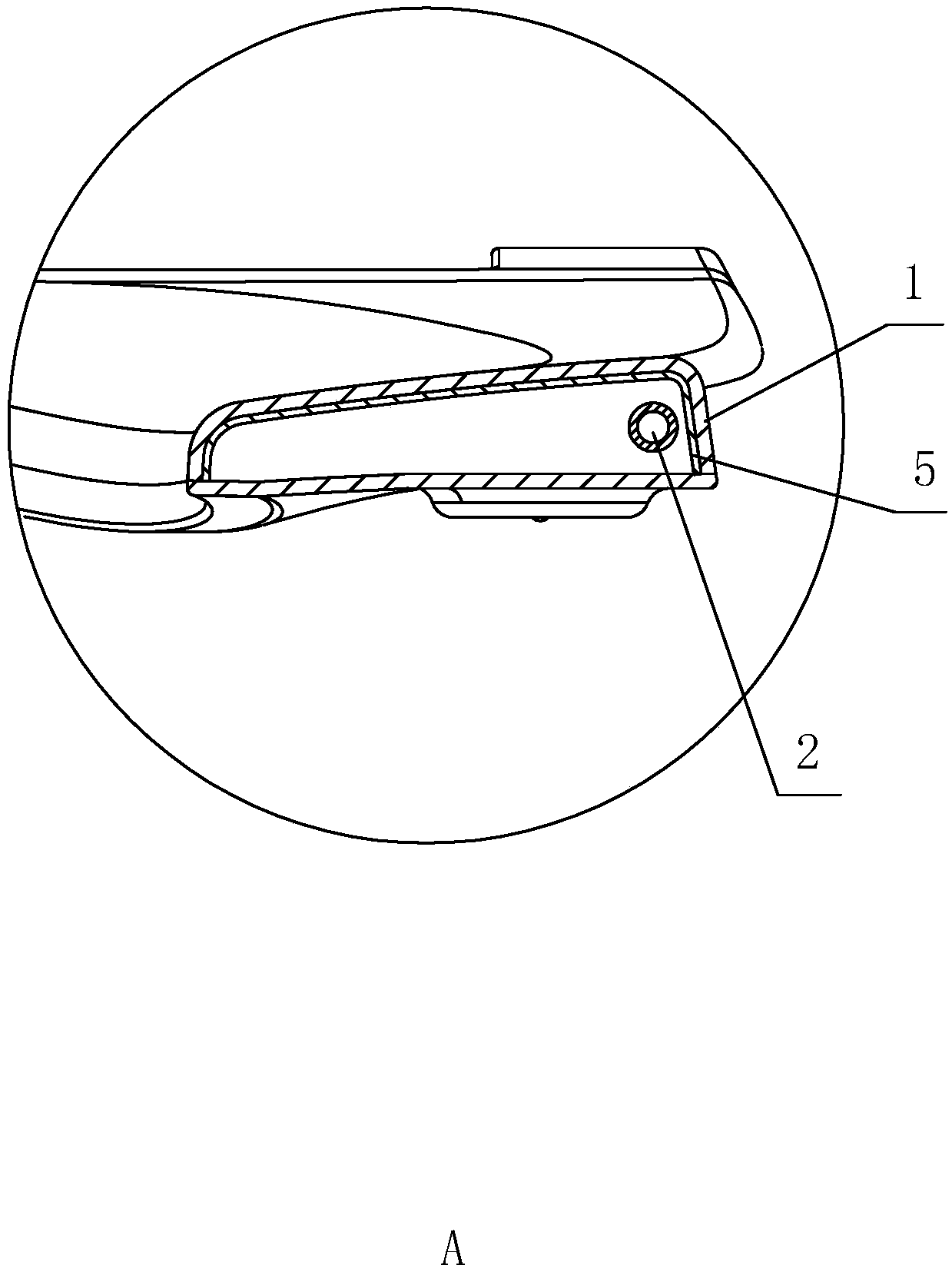

[0034] refer to Figure 1 to Figure 9 The present invention will be further described.

[0035] Such as Figure 5-6 As shown, a constant temperature seat ring includes a base layer 6 of the seat ring, a heating layer and an insulating layer 8 are sequentially arranged above the base layer 6 of the seat ring, and the heating layer is a heating film 7 located above the base layer 6 of the seat ring, and also includes The safe extra-low voltage DC power supply used to supply power to the heating film 7, the preferred voltage of the safe extra-low voltage DC power supply is 12-24V, using a safe voltage range can ensure that the heating film 7 heats up enough, so that the surface of the seat ring The heating temperature on the insulating layer 8 is sufficient, and at the same time, the user's fear of electric shock can be eliminated to achieve a safer purpose. .

[0036] Among them, the base layer 6 of the seat ring is injection-molded by thermoplastic materials such as PP and A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com