Filter net based on formaldehyde purification function

A formaldehyde purification and filter technology, which is applied in the direction of filtration separation, membrane filter, dispersed particle filtration, etc., to achieve the effect of high efficiency utilization, elimination of waste, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

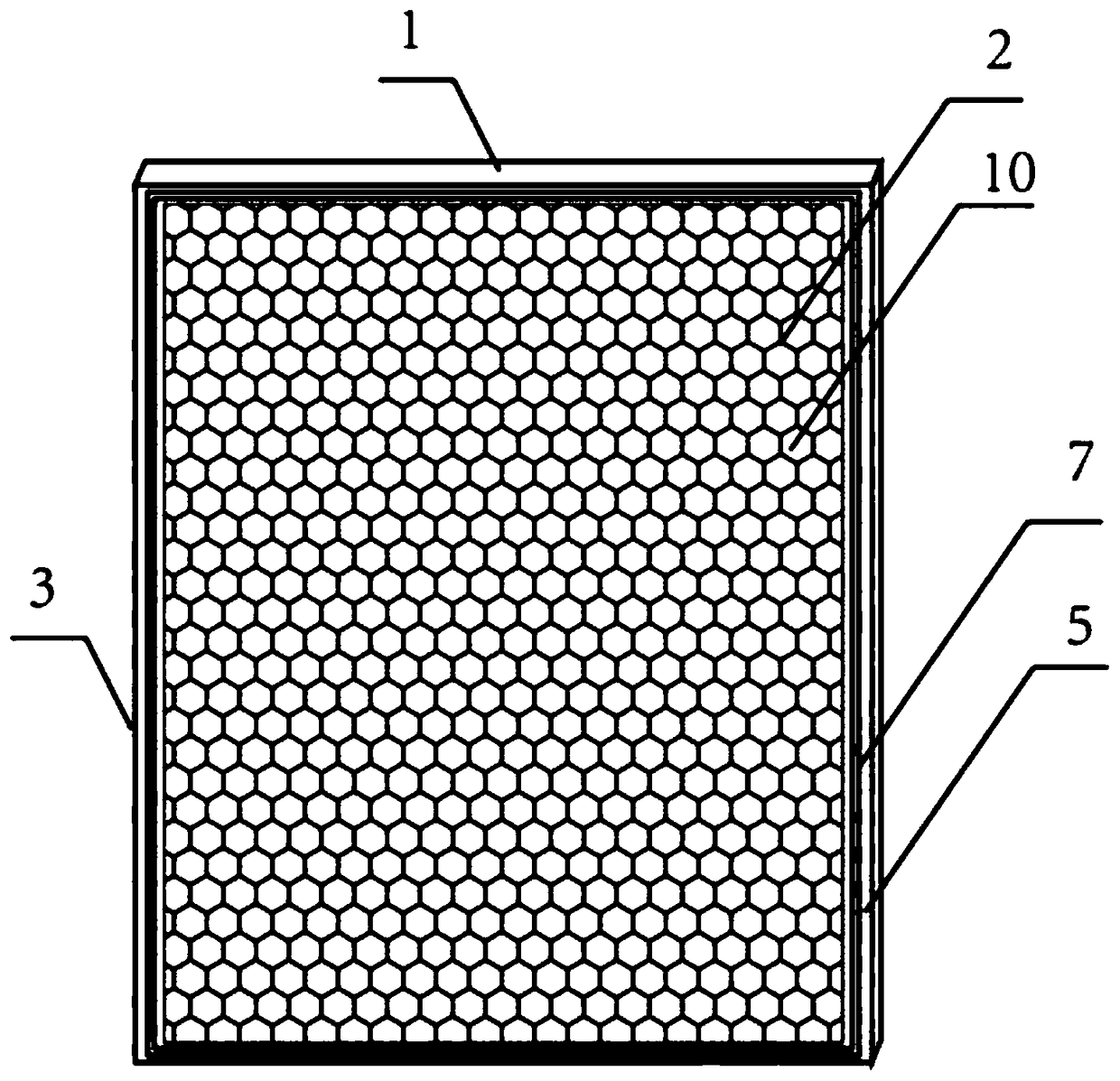

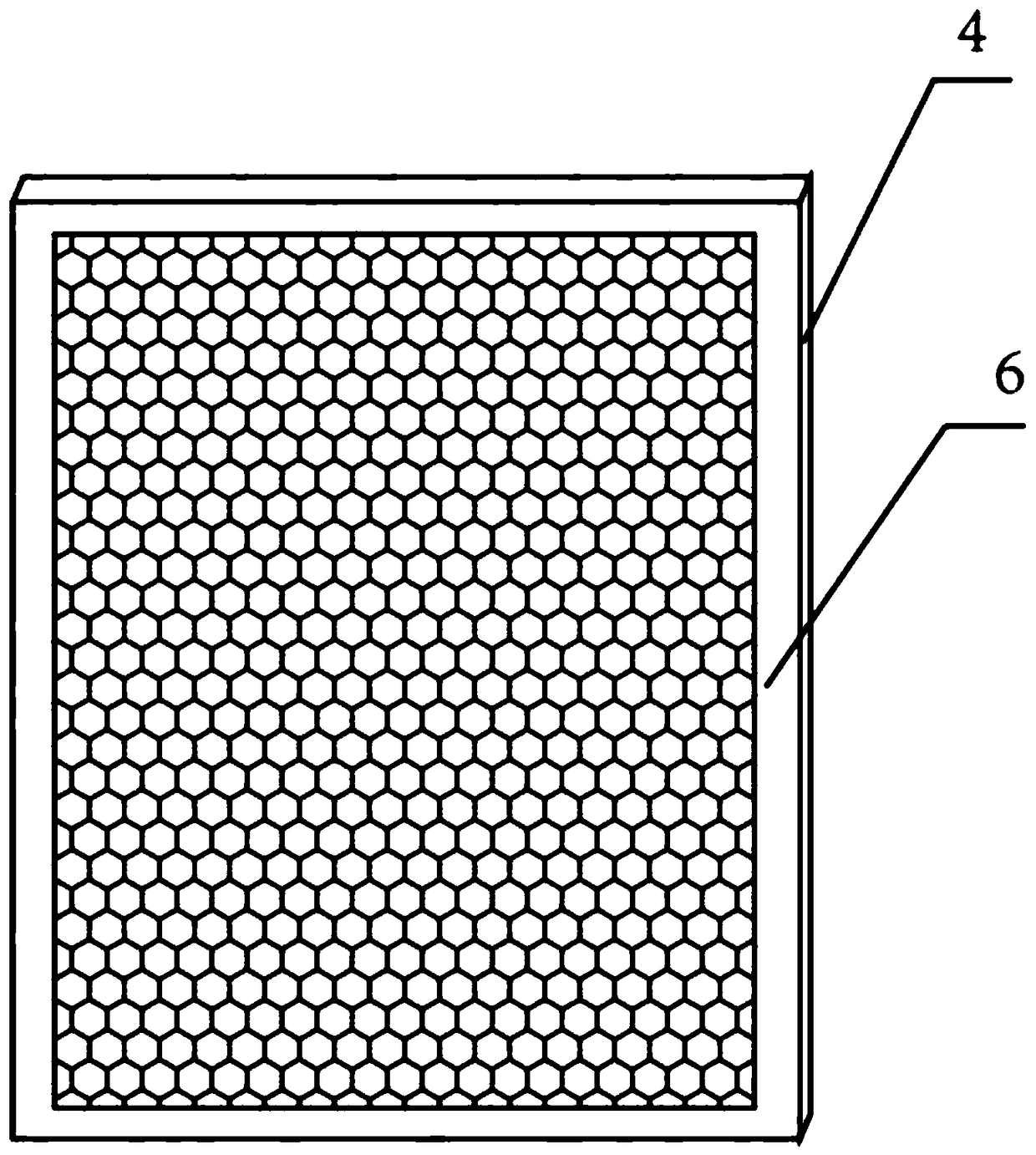

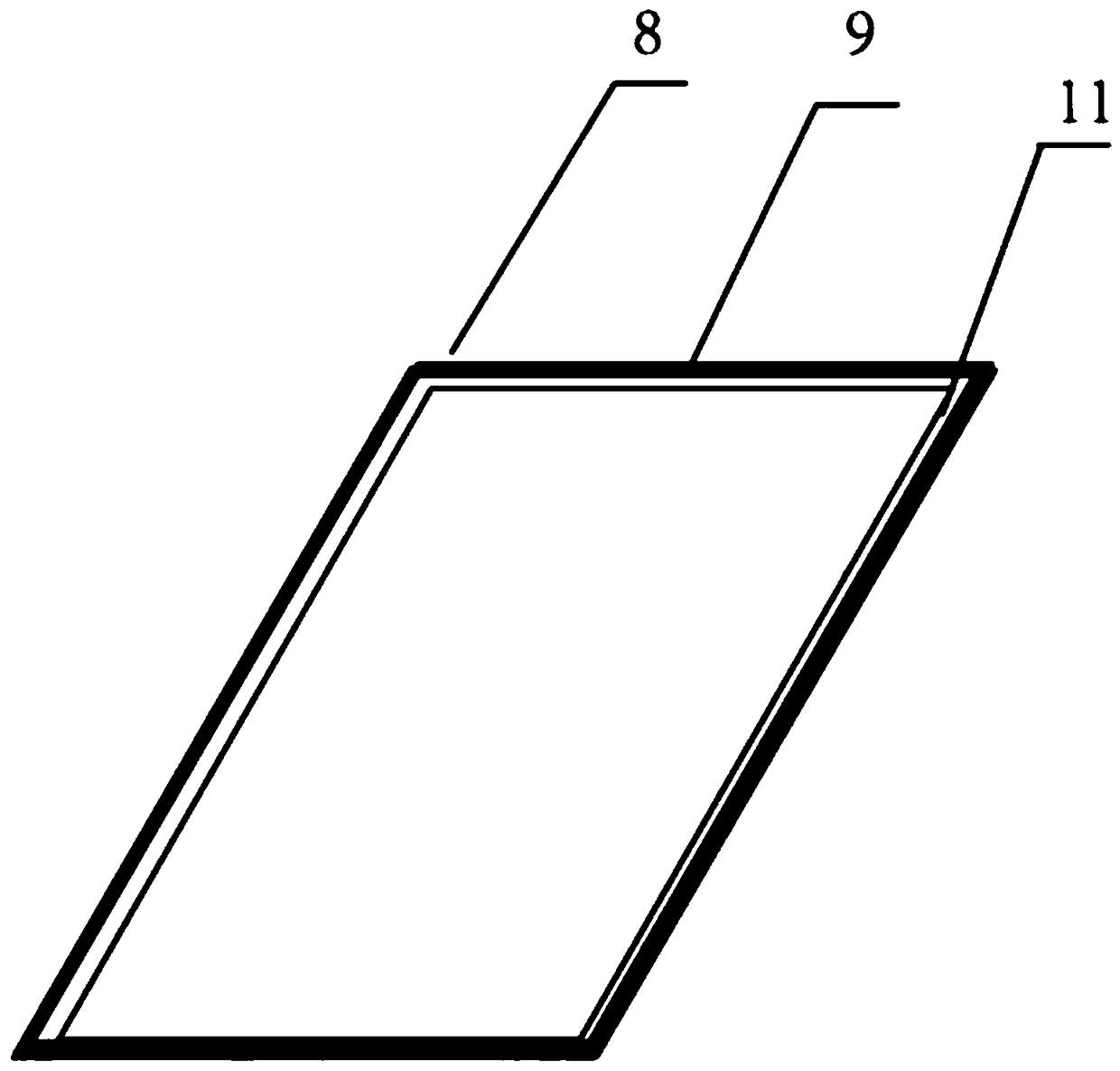

Image

Examples

Embodiment 1

[0031] In this embodiment, a polyester fiber is prepared by melting and blending polyester chips and polyester masterbatches.

[0032] In the polyester fiber, the mass proportions of polyester chips and polyester masterbatch are 90% and 10% respectively; the polyester masterbatch is obtained by mixing and granulating multifunctional fillers and polyester powder, wherein , the mass content of the multifunctional filler is 25-30%; the multifunctional filler is composed of Ca-ZnO nanoparticles, TiO 2 Nanoparticles, CuO nanoparticles, shell powder, MnO 2 Particles and Al 2 o 3 -In 2 o 3 Particle composition.

[0033] The following is the preparation method of the polyester fiber of the present embodiment:

[0034] Step 1. Preparation of Al 2 o 3 -In 2 o 3 Particles: 10ml of In(NO 3 ) 3 ·5H 2O solution, 10ml of Al with a concentration of 0.2mol / L 2 (SO 4 ) 3 Mix the solution with 50ml deionized water evenly, add ammonia water dropwise under stirring, adjust the pH v...

Embodiment 2

[0042] In this embodiment, a polyester fiber is prepared by melting and blending polyester chips and polyester masterbatches.

[0043] In the polyester fiber, the mass proportions of polyester chips and polyester masterbatch are 65% and 35% respectively; the polyester masterbatch is obtained by mixing and granulating multifunctional fillers with polyester powder, Wherein, the mass content of the multifunctional filler is 25-30%; the multifunctional filler is composed of Ca-ZnO nanoparticles, TiO 2 Nanoparticles, CuO nanoparticles, shell powder, MnO 2 Particles and Al 2 o 3 -In 2 o 3 Particle composition.

[0044] The following is the preparation method of the polyester fiber of the present embodiment:

[0045] Step 1. Preparation of Al 2 o 3 -In 2 o 3 Particles: 10ml of In(NO 3 ) 3 ·5H 2 O solution, 10ml of Al with a concentration of 0.2mol / L 2 (SO 4 ) 3 Mix the solution with 50ml deionized water evenly, add ammonia water dropwise under stirring, adjust the pH ...

Embodiment 3

[0053] In this embodiment, a polyester fiber is prepared by melting and blending polyester chips and polyester masterbatches.

[0054] In the polyester fiber, the mass proportions of polyester chips and polyester masterbatch are 76% and 24% respectively; the polyester masterbatch is obtained by mixing and granulating multifunctional fillers with polyester powder, wherein , the mass content of the multifunctional filler is 25-30%; the multifunctional filler is composed of Ca-ZnO nanoparticles, TiO 2 Nanoparticles, CuO nanoparticles, shell powder, MnO 2 Particles and Al 2 o 3 -In 2 o 3 Particle composition.

[0055] The following is the preparation method of the polyester fiber of the present embodiment:

[0056] Step 1. Preparation of Al 2 o 3 -In 2 o 3 Particles: 10ml of In(NO 3 ) 3 ·5H 2 O solution, 10ml of Al with a concentration of 0.2mol / L 2 (SO 4 ) 3 Mix the solution with 50ml deionized water evenly, add ammonia water dropwise under stirring, adjust the pH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com