Xylo-oligosaccharide raw material pounding device

A technology for xylo-oligosaccharides and raw materials, which is applied in the field of xylo-oligosaccharide raw material mashing devices, can solve the problems of high labor cost and mechanical cost, low xylo-oligosaccharide conversion rate, low production efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

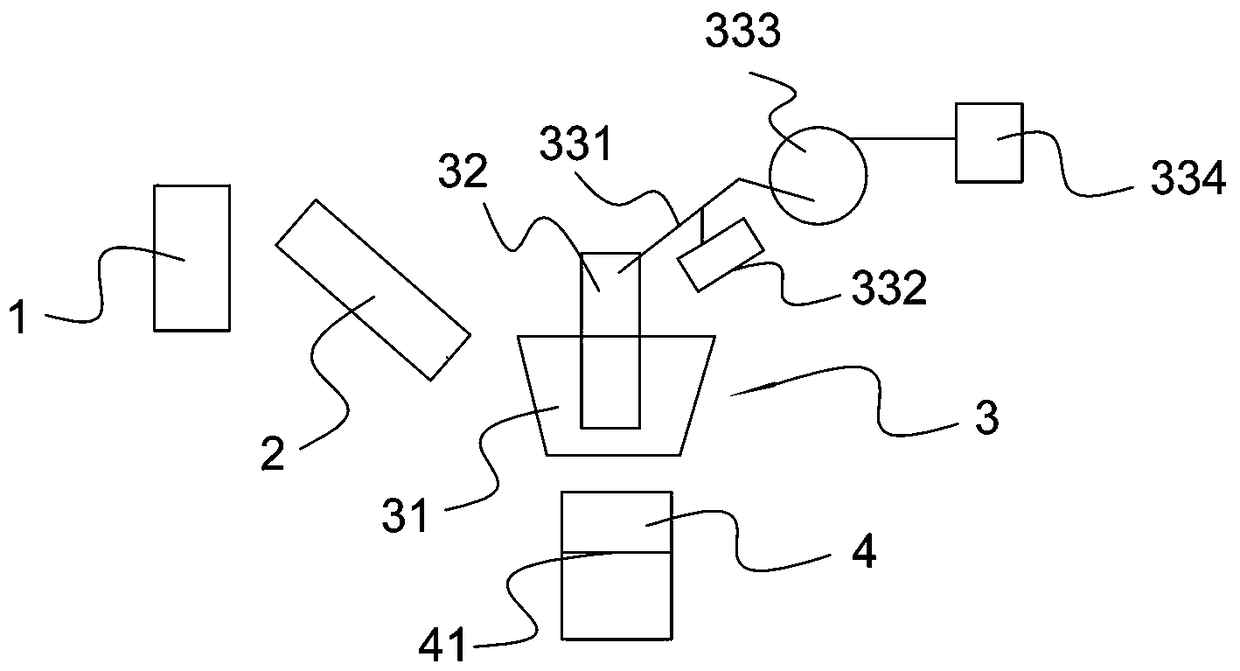

[0019] see figure 1 , the xylo-oligosaccharide raw material crushing device in this embodiment is used to extract xylo-oligosaccharides from rice straw as a xylo-oligosaccharide raw material, including a humidity detection piece for detecting the surface humidity of the xylo-oligosaccharide raw material, used for When the humidity detected by the humidity detection part is greater than the preset humidity, the xylo-oligosaccharide raw material is baked for a preset time. The drying chamber for dry xylo-oligosaccharide raw material 1 is used to mash the dry xylo-oligosaccharide raw material into xylo-oligosaccharide raw material. Mashing part 3 for sugar raw material puree, conveying part 2 for conveying dry xylo-oligosacch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com