An automatic coloring tape device for circular sockets

A circular socket, automatic technology, applied in the device, coating, circuit/collector parts and other directions of coating liquid on the surface, can solve the problems such as hindering the production efficiency of products, affecting the coating ribbon, etc., to achieve universality , Reduce the amount of labor, the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solution of the present invention will be further described through specific implementation manners below in conjunction with the accompanying drawings.

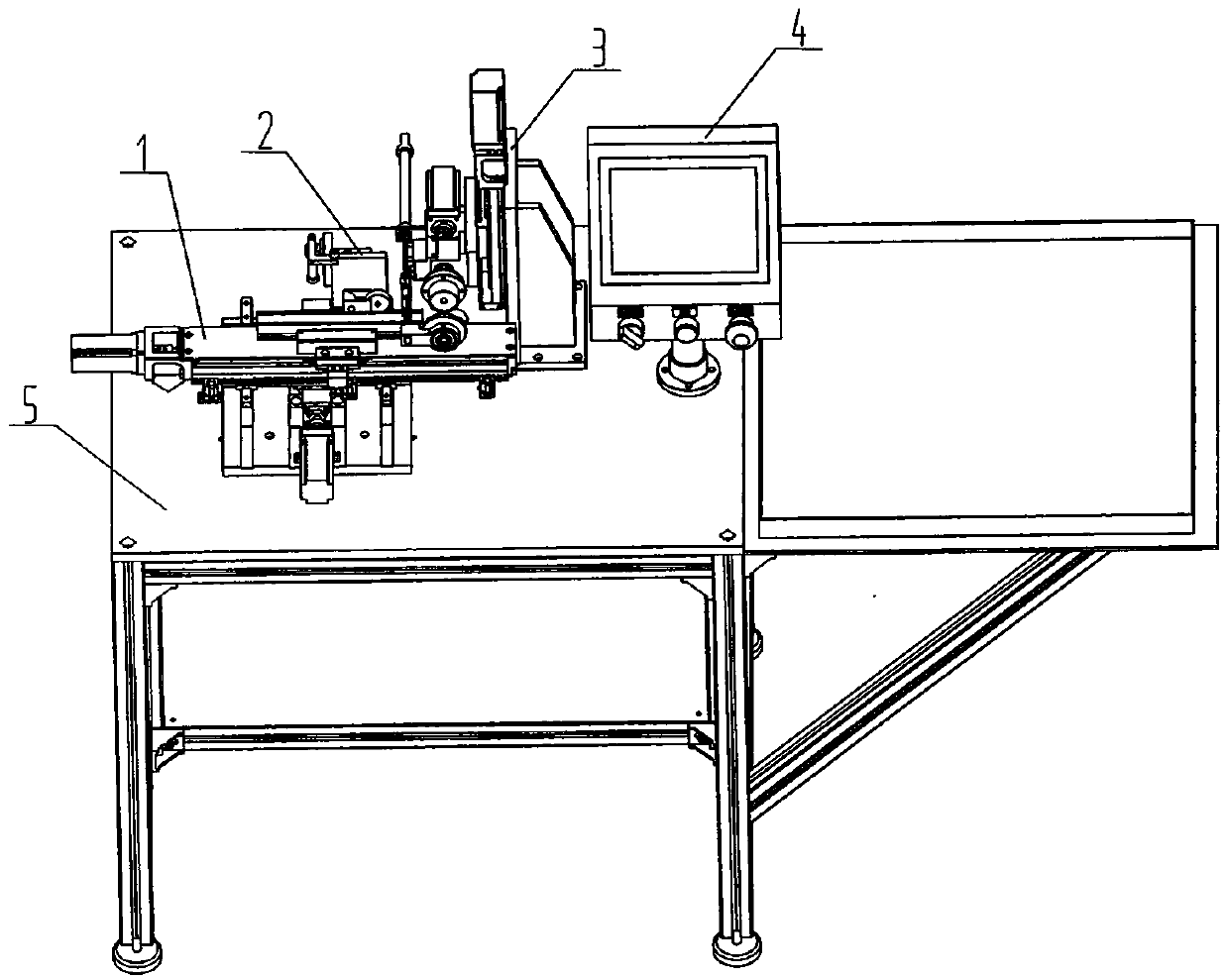

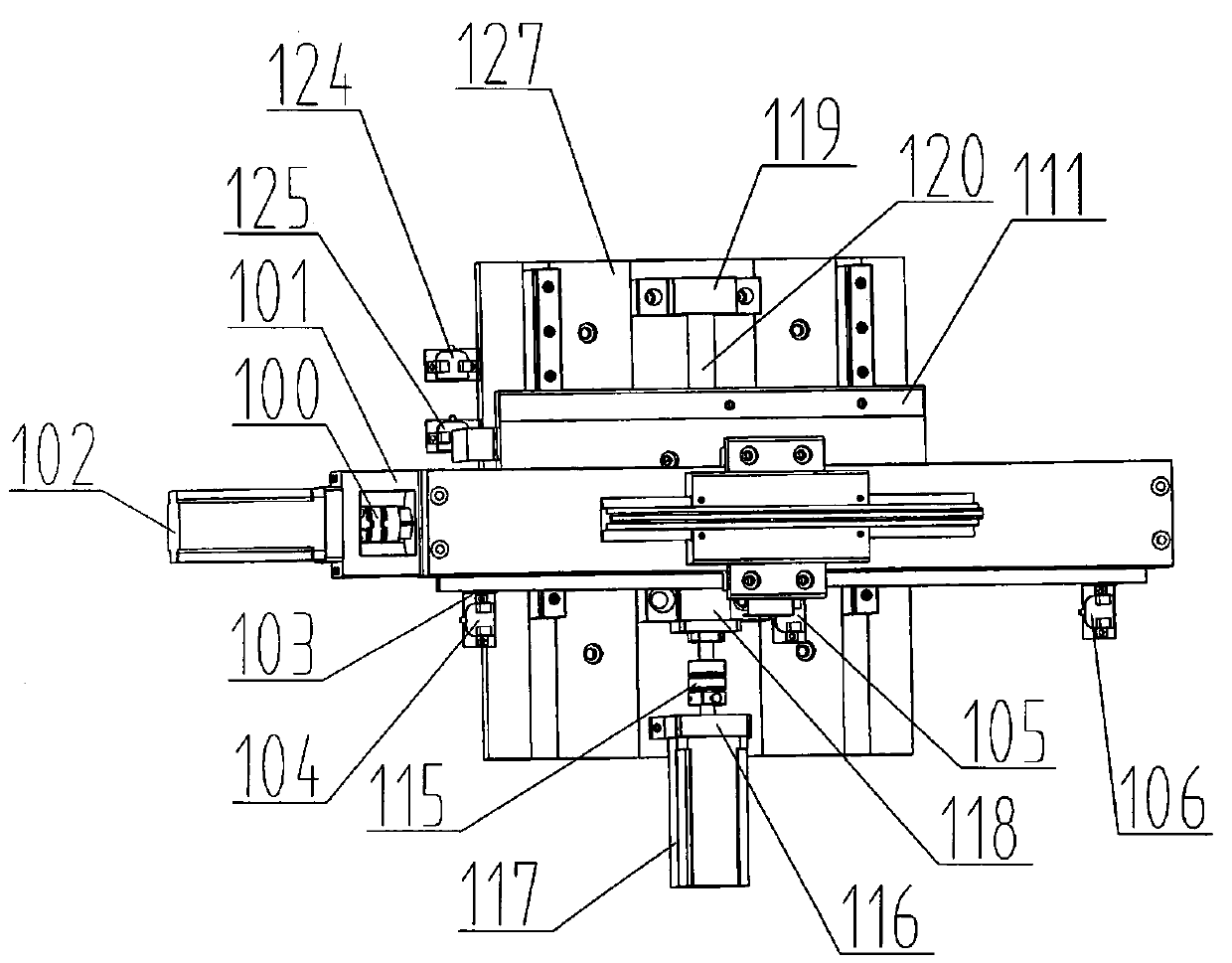

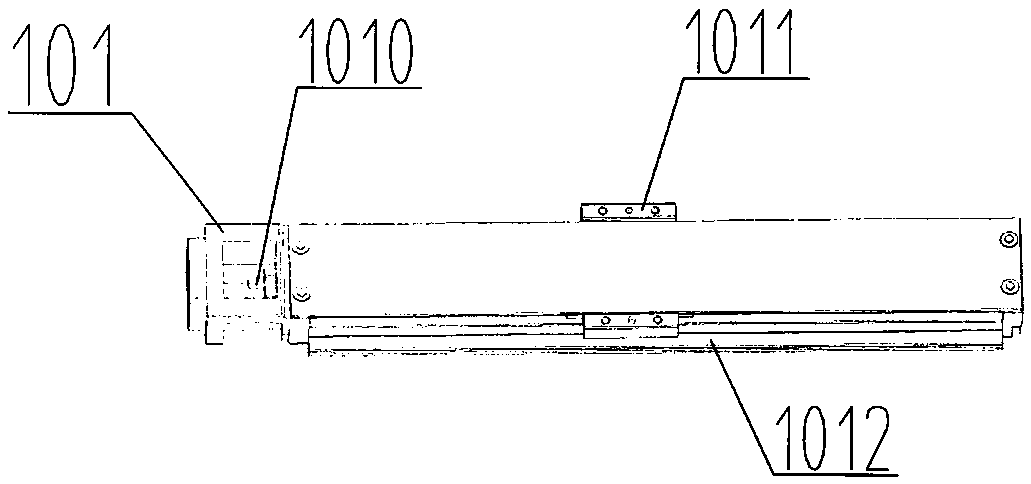

[0037] Such as figure 1 As shown, an automatic ribbon coating device for a circular socket includes a workbench 5, functional components arranged on the workbench panel 500, and a control mechanism that controls the cooperation of various mechanisms in the functional components. The functional components include a coating mechanism 1 , Inking mechanism 2 and rotating follow-up mechanism 3, the control mechanism 4 controls the coating mechanism 1 to drive the coating seat 109 to move rightward to the predetermined position below the ink mechanism 2, and simultaneously controls the inking wheel 215 on the ink mechanism 2 to press down To the surface of the transfer coating strip 110 on the coating seat 109, in the process of the coating seat 109 continuing to move to the right, the inking wheel 215 rotates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com