Rapid assembling and tack welding device for longitudinal welds of thin-wall tubes of different diameters

A technology of thin-walled cylinders and longitudinal welds, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of high processing cost, time-consuming and laborious, low reliability, etc., to reduce clamping time and operate quickly Convenience and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

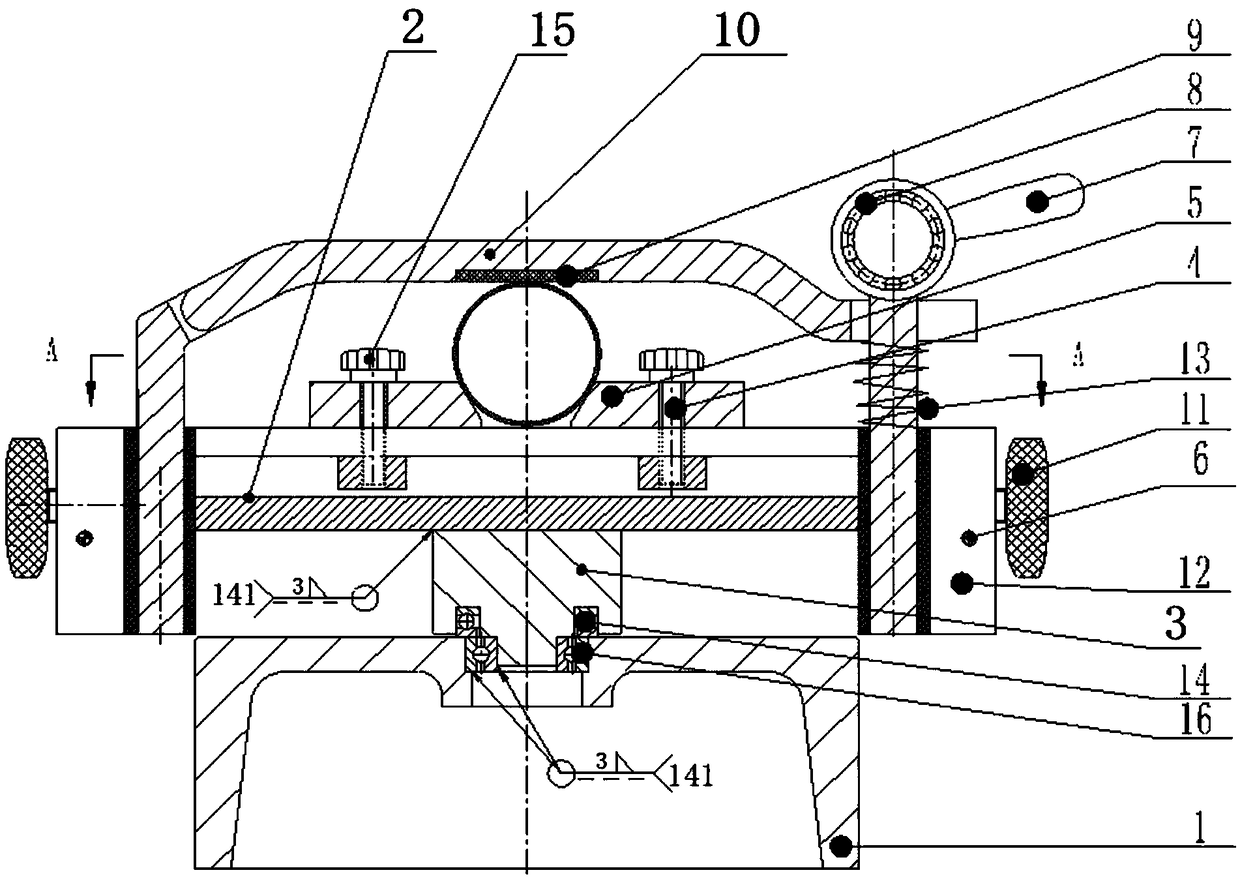

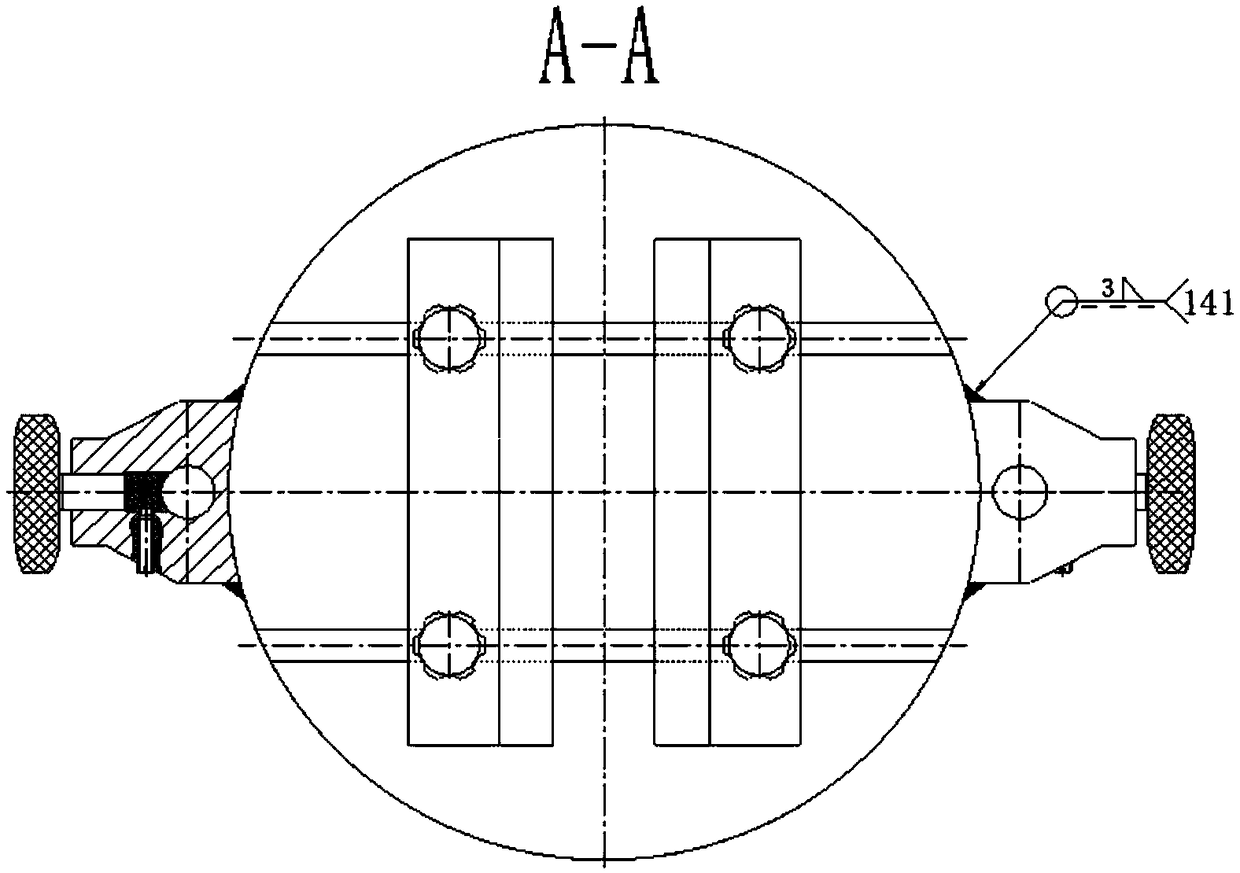

[0029] A rapid assembly positioning welding device for longitudinal welds of thin-walled cylinders with different diameters, which has the advantages of simple product structure, convenient operation, labor-saving and time-saving, and high reliability, such as figure 1 , figure 2 As shown, specifically set to the following structure:

[0030] As an overall concept, the device should include a support seat 1, an installation base 2, a sliding positioning seat assembly, and a compression locking assembly; the support seat 1 is used as a support platform in the device, and is machined from a 45# steel plate of a certain specification. The bottom is a hollow structure to reduce the weight of the parts; the installation base 2 is used as the installation and support platform for each part in the device, and is machined from a 45# steel plate of a certain specification.

[0031] The installation base 2 is fixedly installed on the top of the support base 1 by bolts or welding, and ...

Embodiment 2

[0039] This embodiment is further optimized on the basis of the above-mentioned embodiments, further to better realize the present invention, especially adopt the following configuration structure:

[0040] A locking mounting seat 12 is fixedly connected to both sides of the mounting base 2 by argon arc welding. The locking mounting seat 12 is processed by a certain specification of 45# steel plate. The locking mounting seat 12 is processed with a vertical through pin hole, the locking mounting seat 12 is equipped with a locking bolt 11 and a locking bolt 6 for locking the locking bolt 11, and the locking bolt 11 is processed with textured knurling to facilitate manual operation; the pin of the pressure plate assembly 10 The shaft is movably inserted in the pin hole of a locking mount 12, the pin shaft of the eccentric lock assembly 7 is movably inserted in the pin hole of another locking mount 12, the pin shaft of the pressure plate assembly 10 and the eccentric lock assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com