A high-precision intelligent numerical control machine tool

A CNC machine tool, high-precision technology, applied in the direction of automatic control devices, metal processing machinery parts, manufacturing tools, etc., can solve the problem of inability to control the accuracy of the movement of the spindle box, the inability to automatically adjust the position of the workbench, and the inability to adjust the rotation speed of the cutter, etc. problem, achieve the effect of saving time, improving practicality and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

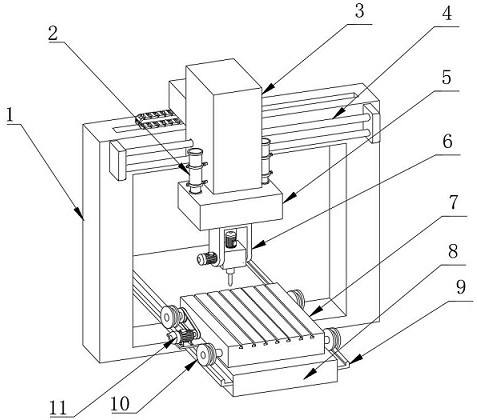

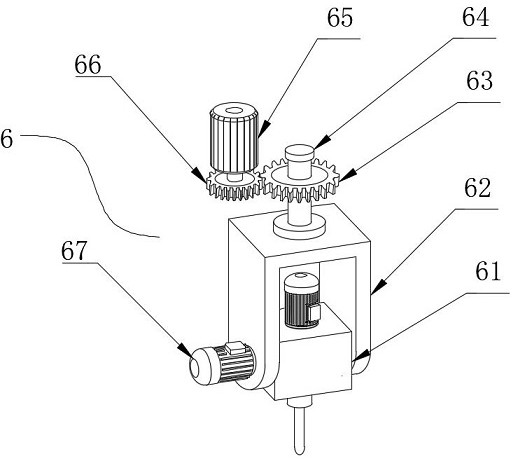

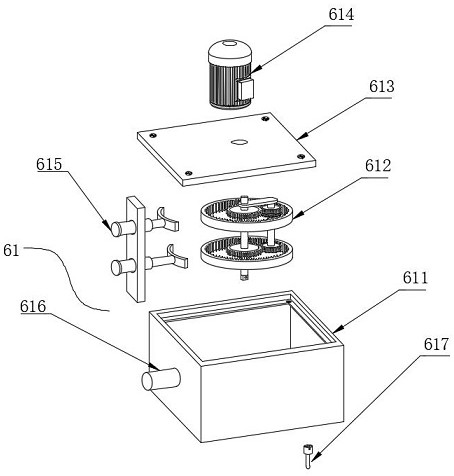

[0030] see Figures 1 to 7 In the embodiment of the present invention, a high-precision intelligent CNC machine tool includes a frame 1, the front side of the upper end of the frame 1 is slidably connected with a headstock 3, and the front side of the frame 1 penetrates through the inner fixed connection of the headstock 3 There is a guide rod 4, the bottom end of the inner side of the frame 1 is fixedly connected to the machine base 8, both ends of the spindle box 3 are fixedly connected with a cylinder 2, and the bottom end of the cylinder 2 is fixedly connected to the lower end of the spindle box 3. A feed box 5 is fixedly connected , the bottom end of the feeding box 5 is embedded with the adjusting device 6, the two ends of the machine base 8 are fixedly connected with the guide rails 9, and the top of the guide rails 9 are connected in a rectangular sliding manner with four track wheels 10, and the inner side of the track wheels 10 is provided with The worktable 7, one e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com