Self-maintenance shock absorber bracket and preparation method thereof

A shock absorber and self-maintenance technology, applied in suspension, elastic suspension, transportation and packaging, etc., can solve problems such as inconvenient maintenance of shock absorber brackets, rust of shock absorber brackets, failure of shock absorbers, etc., to achieve Improve anti-collision and anti-seismic effects, avoid mechanical collisions, and prevent material breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] According to another aspect of the present invention, there is provided a method for preparing a self-maintaining shock absorber bracket. The method for preparing a self-maintaining shock absorber bracket includes:

[0043] Smelting high-purity alloys as raw materials, and processing the raw materials into blanks for mounting bottom plate and shock absorber fixing plate respectively;

[0044] Pre-open mounting holes and through holes for the blanks to obtain semi-finished products of the mounting base plate;

[0045] Forging and rolling of semi-finished installation bottom plate and shock absorber fixing plate blanks to obtain finished installation bottom plate and shock absorber fixing plate;

[0046] Insert the finished product of the shock absorber fixing plate through the through hole on the finished installation bottom plate, and pour the metal solution into the through hole of the finished product direction of the shock absorber fixing plate to obtain the self-maintaining ...

Embodiment 1

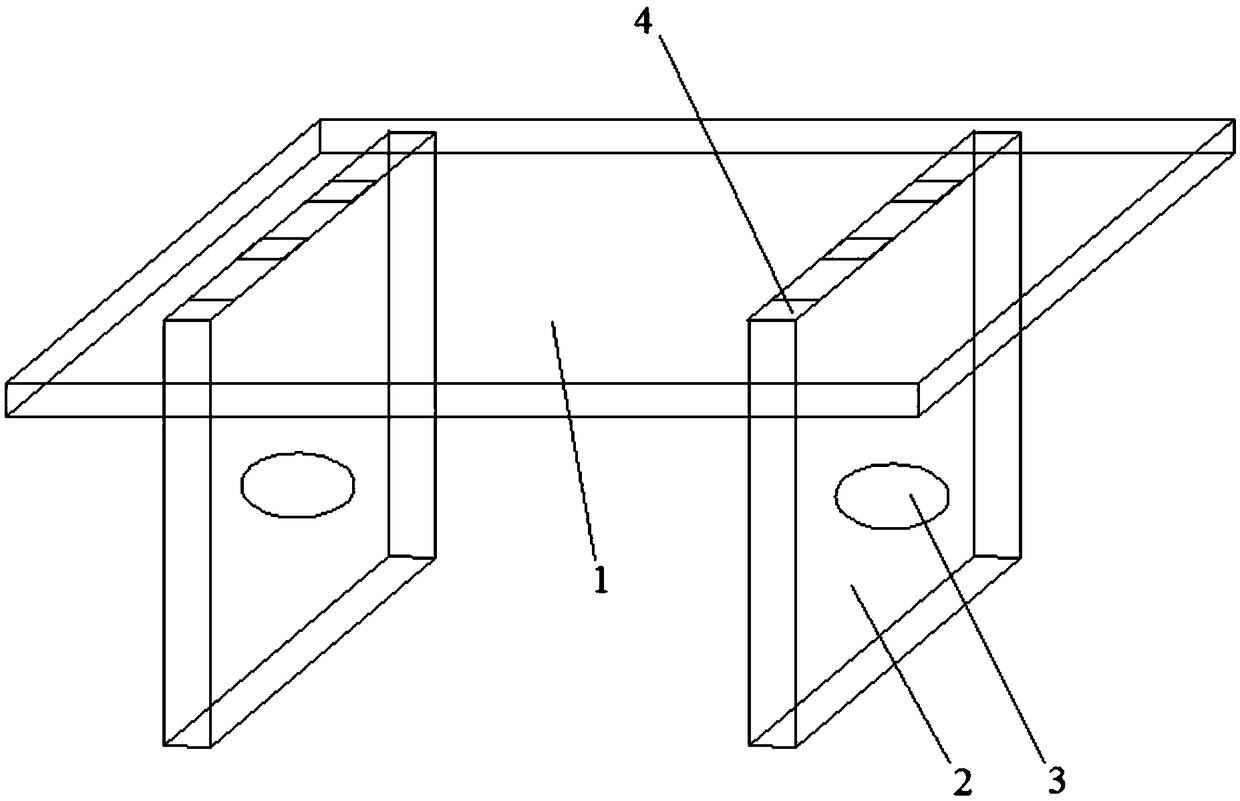

[0055] figure 1 A schematic structural diagram of a self-maintaining shock absorber bracket according to an embodiment of the present invention is shown.

[0056] Such as figure 1 As shown, the self-maintaining shock absorber bracket includes:

[0057] Install the bottom plate 1 and the shock absorber fixing plate 2. The two shock absorber fixing plates 2 are symmetrically arranged at the bottom of the mounting bottom plate 1, and the shock absorber fixing plate 2 is provided with shock absorber fixing holes 4 ;

[0058] Wherein, the mounting base plate 1 is provided with a through hole 3, the shock absorber fixing plate 1 is provided with protrusions, and the shock absorber fixing plate 2 is inserted on the mounting base plate 1 through the protrusions ;

[0059] Wherein, a groove (not shown) is provided on the top of the mounting base plate 1, wear-resistant rubber is provided in the groove, and a plurality of mounting holes are provided on the outer periphery of the mounting bas...

Embodiment 2

[0064] High-purity alloys are smelted through a vacuum consumable furnace, where the high-purity alloys contain: vanadium, chromium, boron, carbon, nickel, manganese, titanium, boron, and iron, and the high-purity alloys are designed as ( wt%): the vanadium: 0.011-0.015, the chromium: 0.001-0.003, the boron: 0.001-0.002, the carbon: 0.12-0.15, the nickel: 0.011-0.019, the titanium: 0.0011 0.0020, the boron: 0.001-0.002, cobalt: 0, molybdenum: 0, the balance is iron and inevitable impurities.

[0065] Smelting high-purity alloys as raw materials, and processing the raw materials into blanks for mounting bottom plate and shock absorber fixing plate respectively;

[0066] Pre-open installation holes and through holes for the rough material to obtain the semi-finished product of the installation base plate;

[0067] Forging and rolling of semi-finished installation bottom plate and shock absorber fixing plate blanks to obtain finished installation bottom plate and shock absorber fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com