Concrete sand-containing water permeable brick core layer and preparation method

A technology of concrete and permeable bricks, which is applied in the field of permeable bricks and can solve problems such as low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

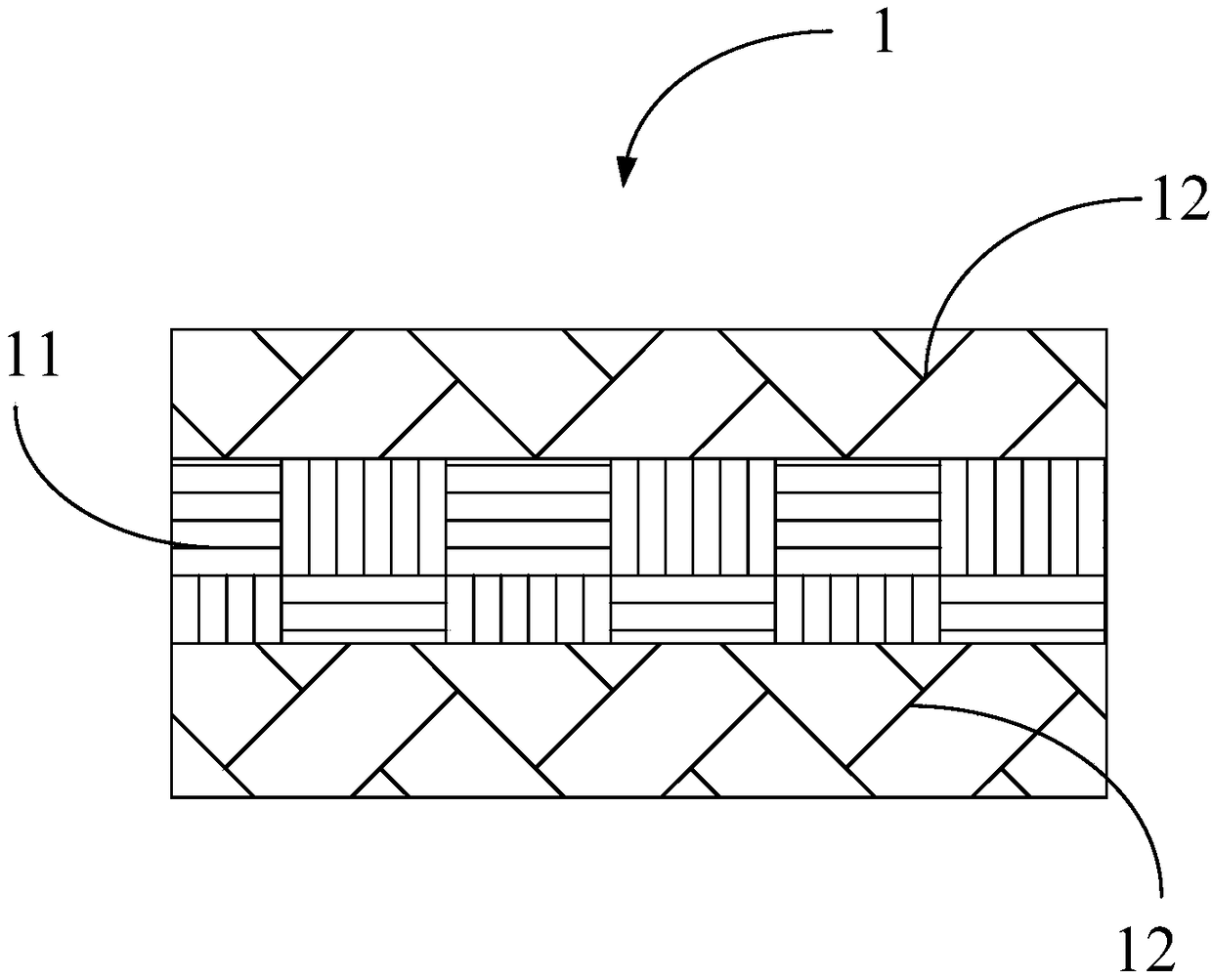

Image

Examples

preparation example Construction

[0080] In addition, in order to solve the above problems, the present invention also provides a method for preparing the core layer of concrete sand-containing permeable bricks, including:

[0081] Step 1: Feed and stir with cement, crushed stone 4-8 times the weight of the cement, and sand with 8-15% the weight of the crushed stone as raw materials to obtain the mixed core material;

[0082] Step 2, filling the mixed core material into the core layer mold to obtain the molding material to be determined;

[0083] Step 3, vibrating and pressurizing the material to be shaped.

[0084] Preferably, in the step 1, the stirring time for feeding and stirring the raw materials is 5 minutes.

[0085] Preferably, in said step 3, vibration pressurization includes:

[0086] Vibrate the material to be shaped at a vibration frequency of 3800 times / second, and at the same time vibrate at 150KN / m 2 Pressurize under the pressure, carry out vibratory pressurization to described shaping mater...

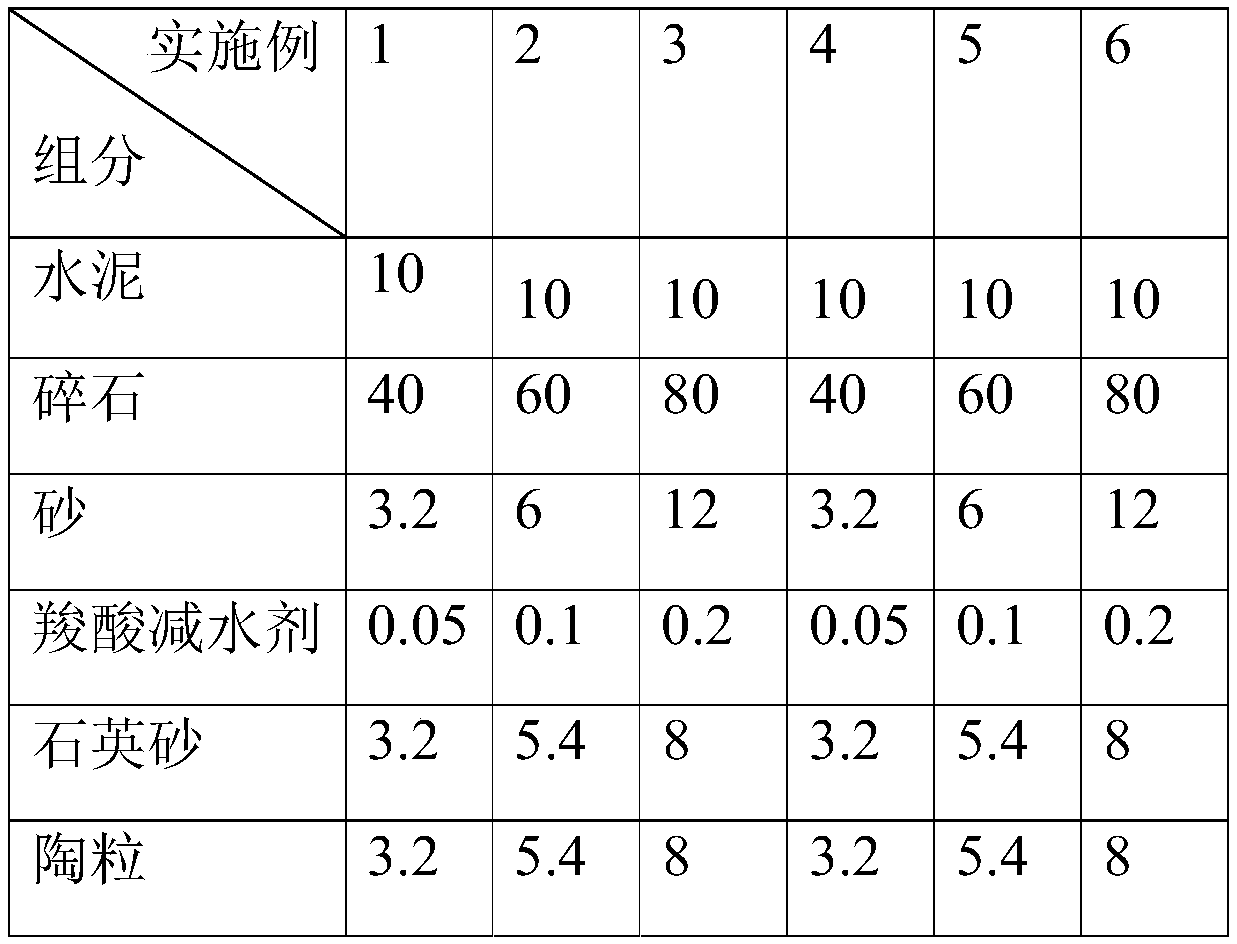

Embodiment 1-3

[0101] Embodiment 1-3 prepares brick core layer step:

[0102] S1, using cement, crushed stone, sand, carboxylic acid water reducer, quartz sand, ceramsite and emulsifier as raw materials according to the formula in Table 1 for feeding and stirring, and the stirring time is 5 minutes to obtain a mixed core material;

[0103] S2, filling the mixed core material into the core layer mold to obtain the material to be finalized;

[0104] S3, vibrate and pressurize the material to be shaped, vibrate the material to be shaped at a vibration frequency of 3800 times / second, and simultaneously 2 Pressurize under the pressure, carry out vibratory pressurization to described shaping material. Instantly.

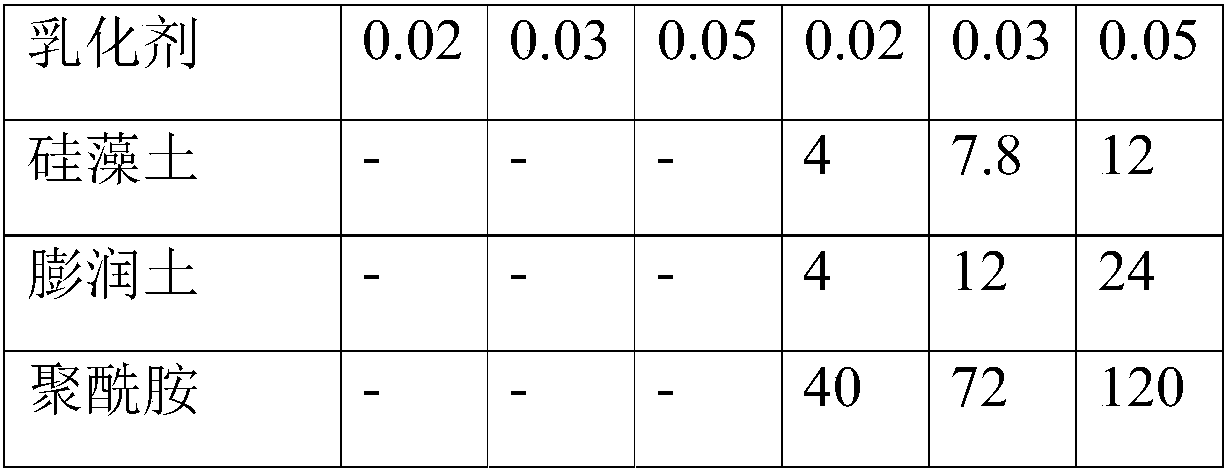

Embodiment 4-6

[0105] Prepare brick core layer step among the embodiment 4-6:

[0106] S4, take diatomaceous earth, bentonite, and polyamide according to the raw material formula in each embodiment in Table 1, and stir and mix with a mixer for 15 minutes to obtain the inner core mixture;

[0107] S5, continuously shearing and stretching the mixed inner core mixture in a vacuum state to form a multi-layer composite soft mesh polyamide mixed film;

[0108] S6, put the soft mesh polyamide mixed film into the mold, vibrate the raw material in the mold at a vibration frequency of 3800 times / second, and at the same time, vibrate at a frequency of 150KN / m 2 Pressurize under the pressure to obtain the inner core layer;

[0109] S7, the inner core layer is placed in the middle, and the outer surrounding core layer (the outer surrounding core layer finally obtained in step S3) is coated on the upper and lower sides of the inner core layer to form a plurality of layers arranged from outside to inside....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com