Concrete demolding agent and preparation method thereof

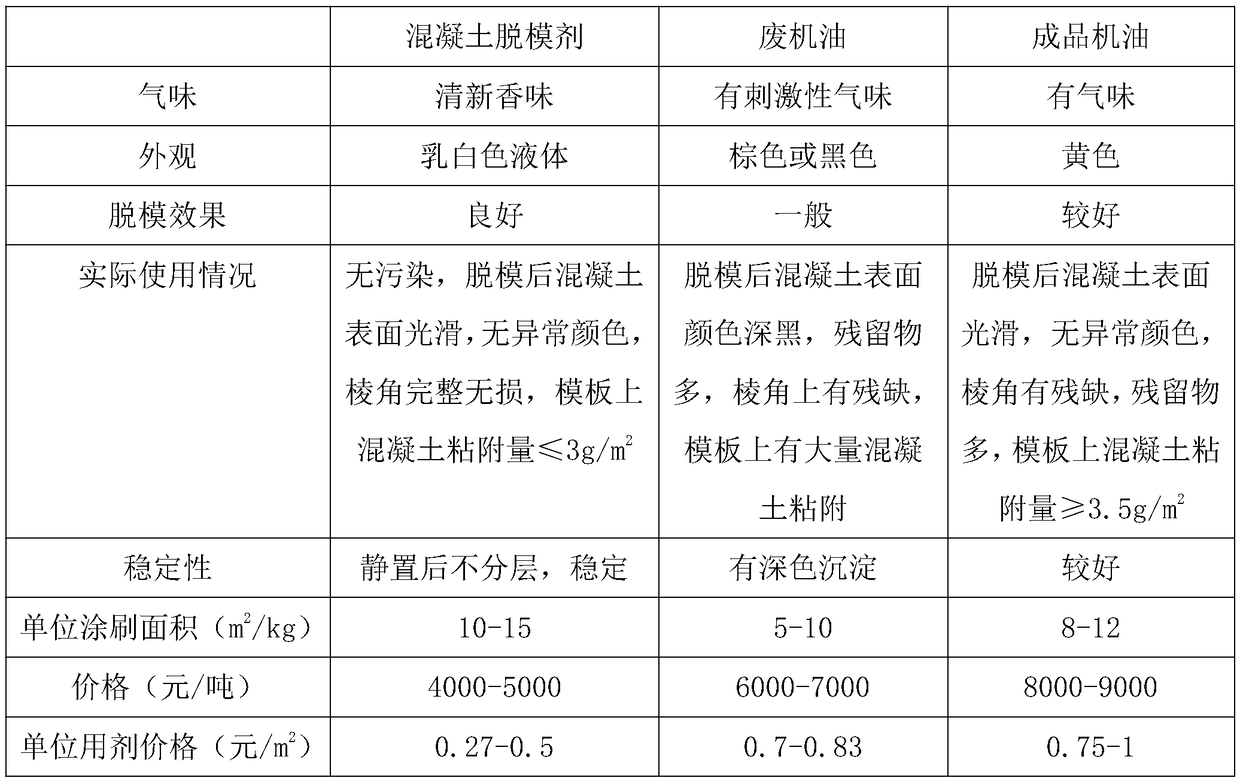

A technology of concrete release agent and thickener, which is applied in the petroleum industry, lubricating compositions, etc., can solve problems affecting construction quality, concrete surface cracking and shelling, etc., and achieve low production equipment and condition requirements, low cost, and high adhesion strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A concrete release agent is characterized in that: it contains the following components in weight percentage: 20% of oily substance, 5% of thickener, 70% of deionized water, 0.5% of preservative, 2% of whitening agent, and Agent 2.5%; wherein the oily substance is machine oil, the thickener is polyacrylamide, the preservative is sodium benzoate, the whitening agent is titanium dioxide, and the odor masking agent is water-soluble spices.

[0026] Its preparation method comprises the following steps:

[0027] S1: Weigh oily substances, thickeners, deionized water, preservatives, brighteners, and odor-masking agents by weight percentage;

[0028] S2: Put the deionized water and thickener into the stainless steel tank, mix and stir for 10 minutes with a disperser, and the viscosity of the material should reach 15cSt;

[0029] S3: adding oily substances, preservatives, whitening agents, and odor-masking agents to the material obtained in step S2, and mixing and stirring for...

Embodiment 2

[0035] A concrete release agent is characterized in that: it contains the following components in weight percentage: 35% of oily substance, 1% of thickener, 60% of deionized water, 0.3% of preservative, 3% of whitening agent, and odor masking agent Agent 2.7%; wherein the oily substance is saponified oil, the thickener is carboxymethyl starch, the preservative is potassium sorbate, the whitening agent is titanium dioxide, and the odor masking agent is water-soluble perfume.

[0036] Its preparation method comprises the following steps:

[0037] S1: Weigh oily substances, thickeners, deionized water, preservatives, brighteners, and odor-masking agents by weight percentage;

[0038] S2: Put the deionized water and thickener into the stainless steel tank, mix and stir for 15 minutes with a disperser, and the viscosity of the material should reach 20cSt;

[0039] S3: adding oily substances, preservatives, whitening agents, and odor-masking agents to the material obtained in step ...

Embodiment 3

[0042] A concrete release agent is characterized in that: it contains the following components in weight percentage: 50% of oily substance, 3% of thickener, 44.9% of deionized water, 0.1% of preservative, 1% of whitening agent, and taste masking 1% agent; wherein the oily substance is saponified oil, the thickener is sodium carboxymethyl cellulose, the preservative is potassium sorbate, the whitening agent is titanium dioxide, and the flavor masking agent is water-soluble perfume.

[0043] Its preparation method comprises the following steps:

[0044] S1: Weigh oily substances, thickeners, deionized water, preservatives, brighteners, and odor-masking agents by weight percentage;

[0045] S2: Put the deionized water and thickener into the stainless steel tank, mix and stir for 20 minutes with a disperser, and the viscosity of the material should reach 25cSt;

[0046] S3: adding oily substances, preservatives, brighteners, and odor-masking agents to the material obtained in ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com