Comprehensive recovery technology for dedusting ash of iron smelting furnace

A technology of ironmaking blast furnace and process, which is applied in the field of comprehensive recovery process of ironmaking blast furnace dust removal, and can solve the problems of inability to recover valuable elements, lack of combined recovery technology of the whole industry chain, and inability to achieve comprehensive utilization mode of new building materials, etc. , to achieve the effect of improving work efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

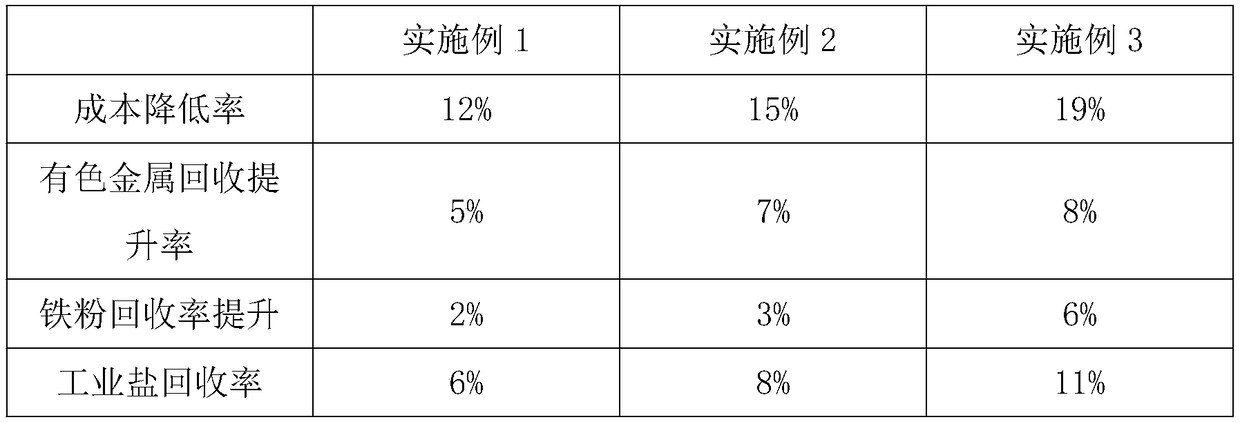

Embodiment 1

[0022] A comprehensive recovery process for iron-smelting blast furnace dust removal, the recovery process is as follows:

[0023] Step 1, passing the soot of the iron-smelting blast furnace into the high-temperature reduction reaction of the rotary kiln, and volatilizing to obtain enriched non-ferrous metals, high-chlorine-containing zinc-oxygen powder and kiln slag;

[0024] Step 2, the rotary kiln slag produced in step 1 is combined to obtain fine powder, iron concentrate and building materials auxiliary materials by means of joint beneficiation;

[0025] Step 3, the zinc oxide powder containing high chlorine is leached, dechlorinated, purified, and electrolyzed to produce refined zinc ingots, and the dechlorination waste liquid is evaporated and crystallized to produce industrial salt;

[0026] Step 4, the zinc extraction leaching residue obtained after leaching in step 3 is subjected to acid leaching, reduction, extraction, replacement, and electrolysis to produce 4N5 ind...

Embodiment 2

[0035] A comprehensive recovery process for iron-smelting blast furnace dust removal, the recovery process is as follows:

[0036] Step 1, passing the soot of the iron-smelting blast furnace into the high-temperature reduction reaction of the rotary kiln, and volatilizing to obtain enriched non-ferrous metals, high-chlorine-containing zinc-oxygen powder and kiln slag;

[0037] Step 2, the rotary kiln slag produced in step 1 is combined to obtain fine powder, iron concentrate and building materials auxiliary materials by means of joint beneficiation;

[0038] Step 3, the zinc oxide powder containing high chlorine is leached, dechlorinated, purified, and electrolyzed to produce refined zinc ingots, and the dechlorination waste liquid is evaporated and crystallized to produce industrial salt;

[0039] Step 4, the zinc extraction leaching residue obtained after leaching in step 3 is subjected to acid leaching, reduction, extraction, replacement, and electrolysis to produce 4N5 ind...

Embodiment 3

[0048] A comprehensive recovery process for iron-smelting blast furnace dust removal, the recovery process is as follows:

[0049] Step 1, passing the soot of the iron-smelting blast furnace into the high-temperature reduction reaction of the rotary kiln, and volatilizing to obtain enriched non-ferrous metals, high-chlorine-containing zinc-oxygen powder and kiln slag;

[0050] Step 2, the rotary kiln slag produced in step 1 is combined to obtain fine powder, iron concentrate and building materials auxiliary materials by means of joint beneficiation;

[0051] Step 3, the zinc oxide powder containing high chlorine is leached, dechlorinated, purified, and electrolyzed to produce refined zinc ingots, and the dechlorination waste liquid is evaporated and crystallized to produce industrial salt;

[0052] Step 4, the zinc extraction leaching residue obtained after leaching in step 3 is subjected to acid leaching, reduction, extraction, replacement, and electrolysis to produce 4N5 ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com