Method for synthesizing NiMnGaCo magnetic memory alloy at high temperature through combustion reaction

A technology of combustion reaction and magnetic memory, which is applied in the field of high-temperature synthesis of NiMnGaCo magnetic memory alloy by combustion reaction, which can solve the problems of poor machining performance and high brittleness of magnetic memory alloy, and achieve the effects of high toughness, reduced grain size and fine structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

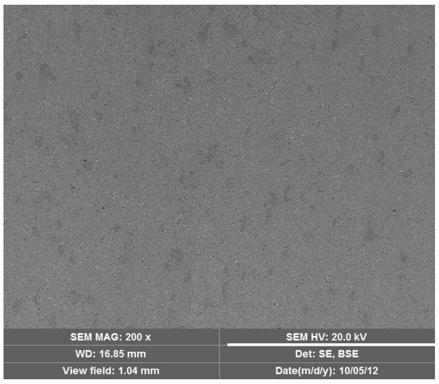

[0025] The preparation method of the high-strength and high-plasticity NiMnGaCo magnetic memory alloy of this embodiment is prepared as follows: Take 46 parts of Ni powder, 25 parts of Mn powder, 25 parts of Ga powder and 4 parts of 5 micron particle size in atomic percentage. The Co powder is mixed, the metal powder is stirred in a mixer at a speed of 200 revolutions / min-500 revolutions / min to make it evenly mixed, then pour it into the pressure forming mold, press the mold with a jack, and press Press the powder into a cylindrical sample with a diameter of 10mm and a height of 10mm under a pressure of 400-1000MPa and holding pressure for 2-4 minutes, and finally sinter it at a temperature of 1000-1200℃ and a holding time of 20-40 minutes. A NiMnGaCo magnetic memory alloy with a particle size of 20-30 microns is obtained.

Embodiment 2

[0027] The preparation method of the high-strength and high-plasticity NiMnGaCo magnetic memory alloy of this embodiment is prepared as follows: Take 50 parts of Ni powder, 25 parts of Mn powder, 25 parts of Ga powder and 1 part of 5 micron particle size in atomic percentage The Co powder is mixed, the metal powder is stirred in a mixer at a speed of 200 revolutions / min-500 revolutions / min to make it evenly mixed, then pour it into the pressure forming mold, press the mold with a jack, and press Press the powder into a cylindrical sample with a diameter of 10mm and a height of 10mm under a pressure of 400-1000MPa and holding pressure for 2-4 minutes, and finally sinter it at a temperature of 1000-1200℃ and a holding time of 30 minutes. NiMnIn magnetic memory alloy with a diameter of 20-30 microns.

Embodiment 3

[0029] The preparation method of the high-strength and high-plasticity NiMnGaCo magnetic memory alloy of this embodiment is prepared as follows: according to atomic percentages, 47 parts of Ni powder with a particle size of 5 microns, 25 parts of Mn powder, 25 parts of Ga powder and 3 parts of Co powder is mixed, and the metal powder is stirred in a mixer at a speed of 200 revolutions / min-500 revolutions / min to make it evenly mixed, then pour it into the pressure forming mold, press the mold with a jack, and press it to Press the powder into a cylindrical sample with a diameter of 10mm and a height of 10mm under pressure of 400-1000MPa and holding pressure for 2-4 minutes, and finally sintering process at a temperature of 1200℃ and a holding time of 20-40 minutes to obtain the particle size It is a 20-30 micron NiMnGaCo magnetic memory alloy.

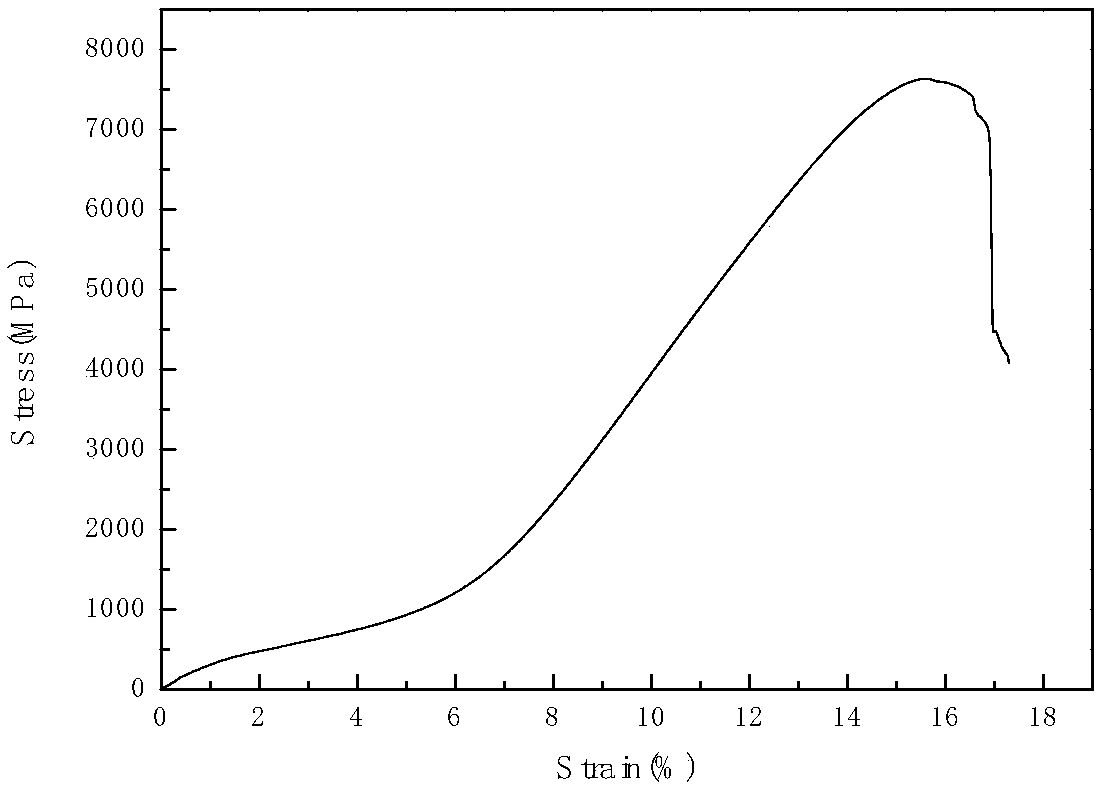

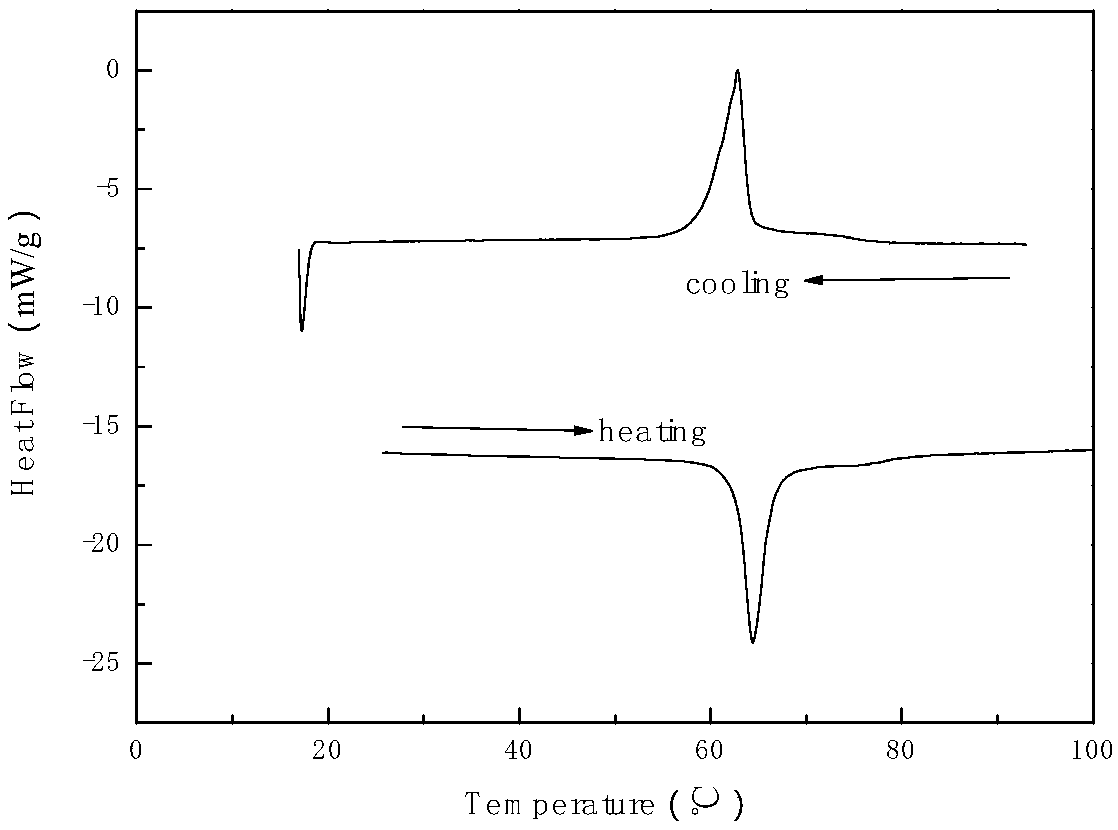

[0030] The high-strength and high-plasticity NiMnGaCo alloy prepared in Example 1 was tested for fracture strength and fracture strain. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com