A method for improving the color fastness to wet rubbing of cellulose fiber indigo dyeing

A technology of cellulose fiber and wet rubbing, which is applied in dyeing, textiles and papermaking, and can solve the problems of low color fastness to wet rubbing of jeans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

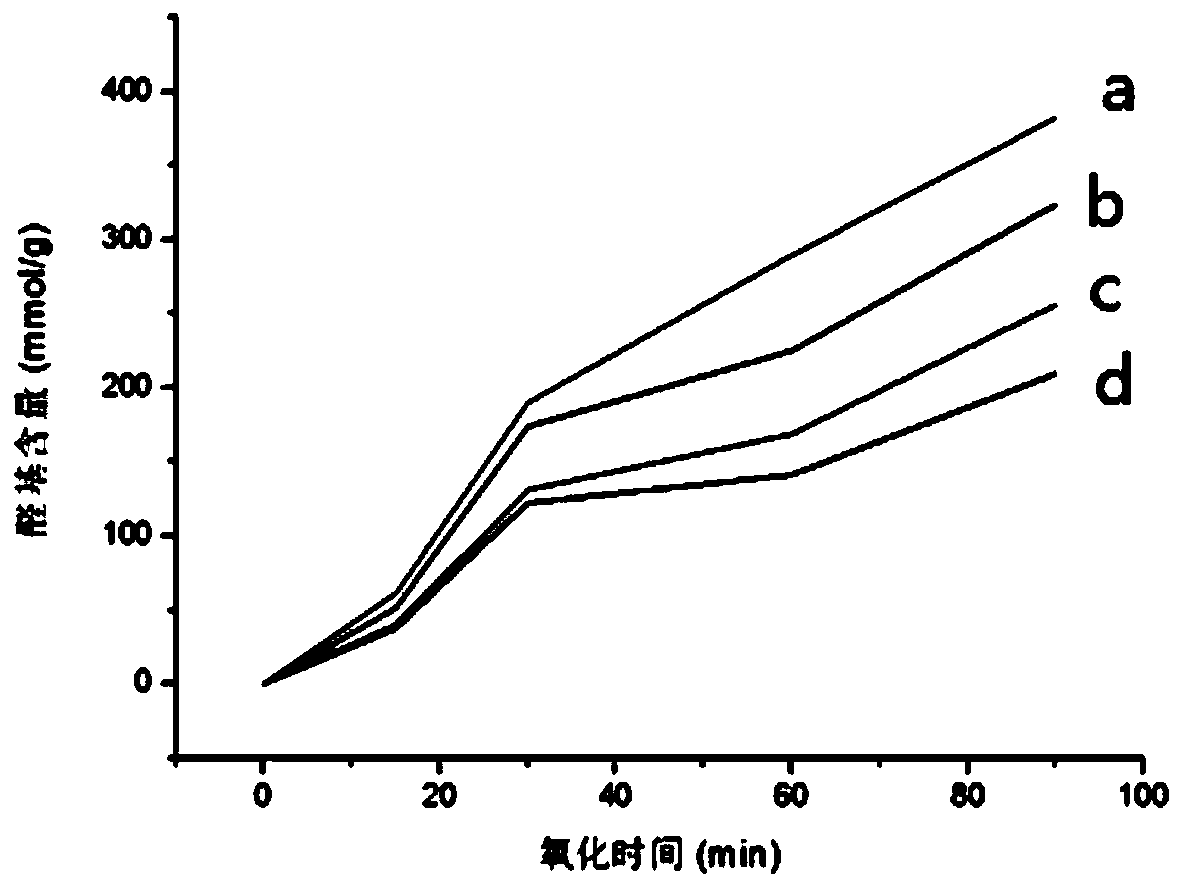

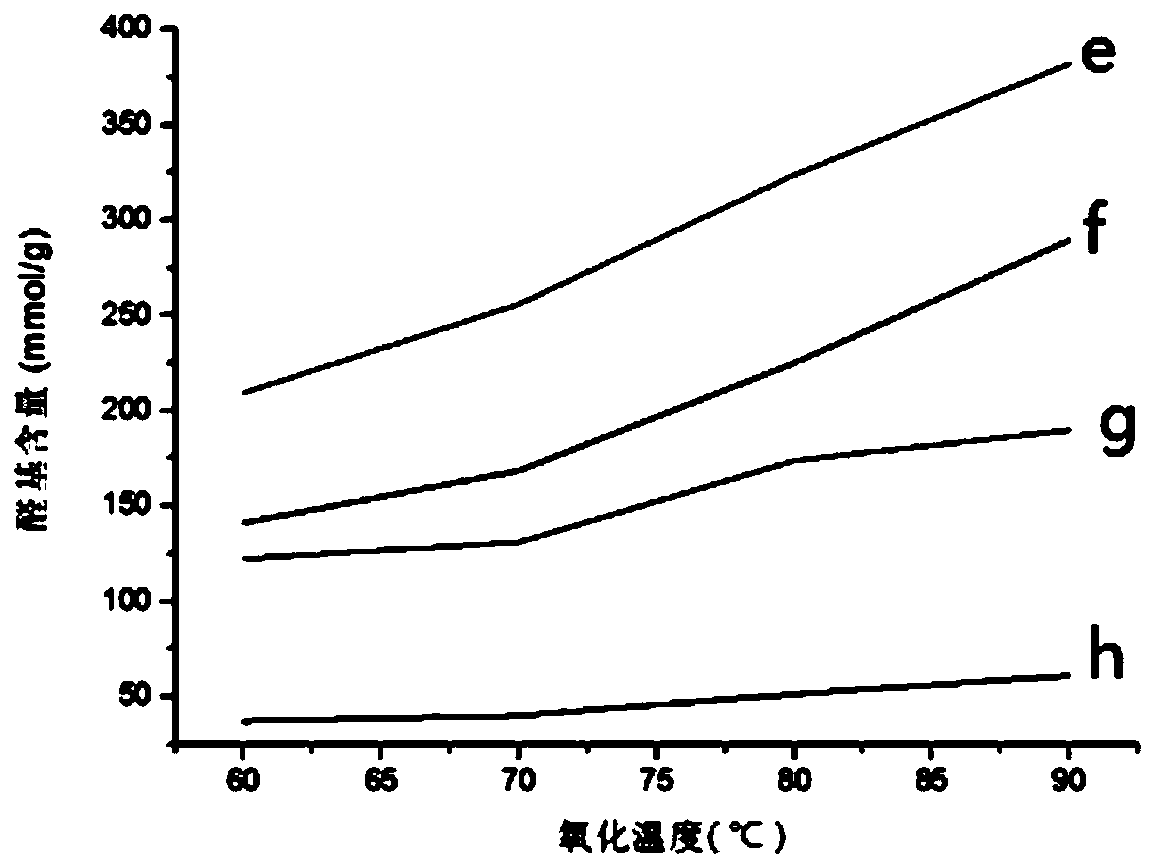

[0014] Specific embodiment one: present embodiment a kind of method that improves the wet rubbing color fastness of cellulose fiber indigo dyeing carries out according to the following steps: 1, the fast concentrated alkali treatment of cellulose fiber: immerse cellulose fiber in the concentrated alkali solution and process 5 ~15s, then squeezed dry by pressing rollers, immersed in clean water for washing, and then immersed in acetic acid aqueous solution with a pH value of 1~2 for padding treatment; 2. Rapid aldylation on the surface of cellulose fibers: heating sodium periodate aqueous solution, Then keep warm, and then cyclically pad the cellulose fiber treated with the acetic acid aqueous solution in step 1 in the sodium periodate aqueous solution, react for 15min to 30min, then squeeze the cellulose fiber through the pressing roller and then immerse it in the glycerol aqueous solution for circular immersion. Rolling, reacting for 5-10 minutes, then squeezed out by pressing...

specific Embodiment approach 2

[0017] Embodiment 2: This embodiment differs from Embodiment 1 in that: the concentrated alkali solution is an aqueous NaOH solution with a concentration of 150 g / L-250 g / L. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0018] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the concentrated alkali solution is an aqueous NaOH solution with a concentration of 180 g / L-200 g / L. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com