WiFi-based automatic metering system for wells

An automatic measurement and weight technology, applied in measurement, wellbore/well components, earth-moving drilling, etc., can solve the problems of increasing the maintenance cost of the scraper, affecting the statistics of production measurement, and inability to know the loading capacity, etc. The time to retrieve data, reduce the number of maintenance, and prevent errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

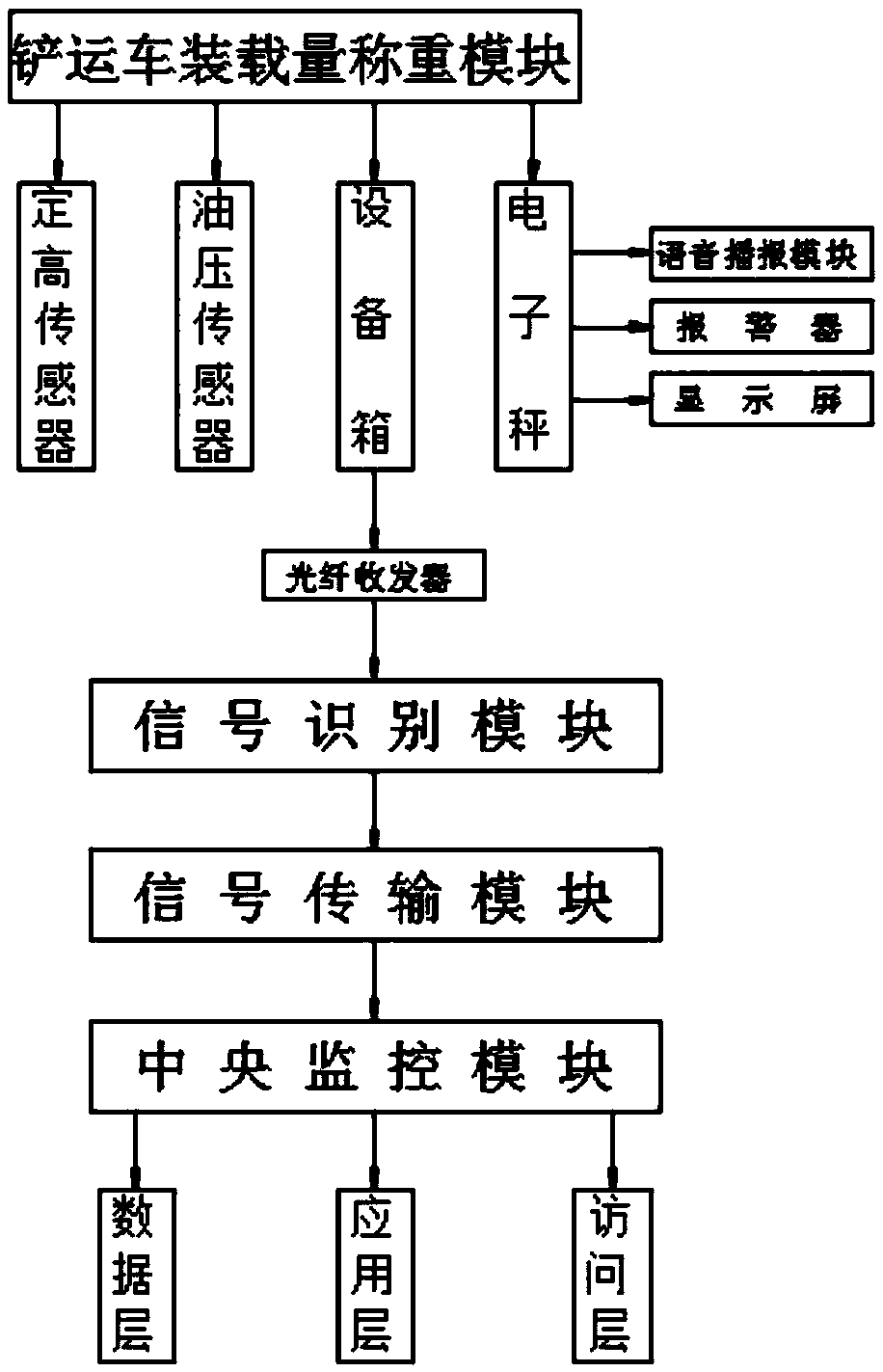

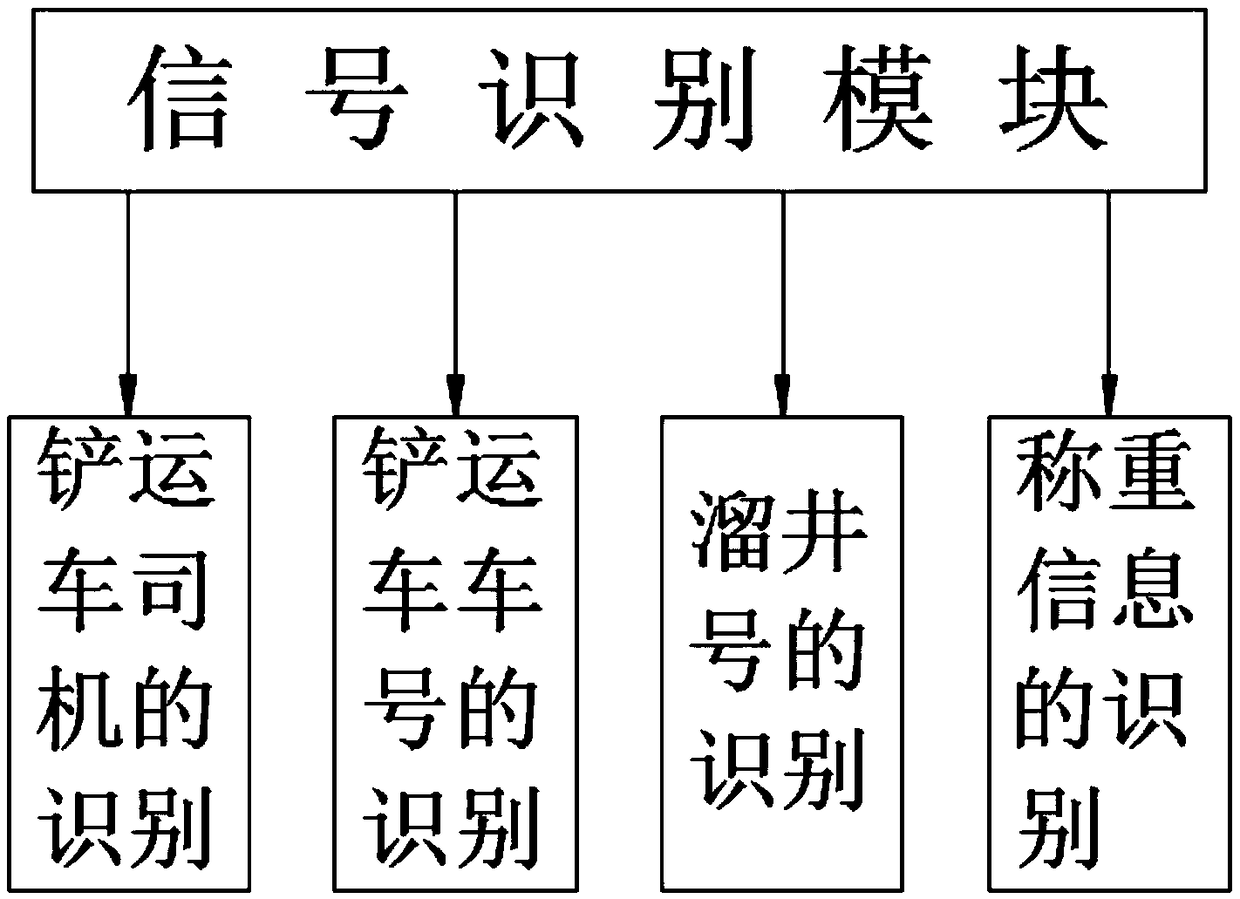

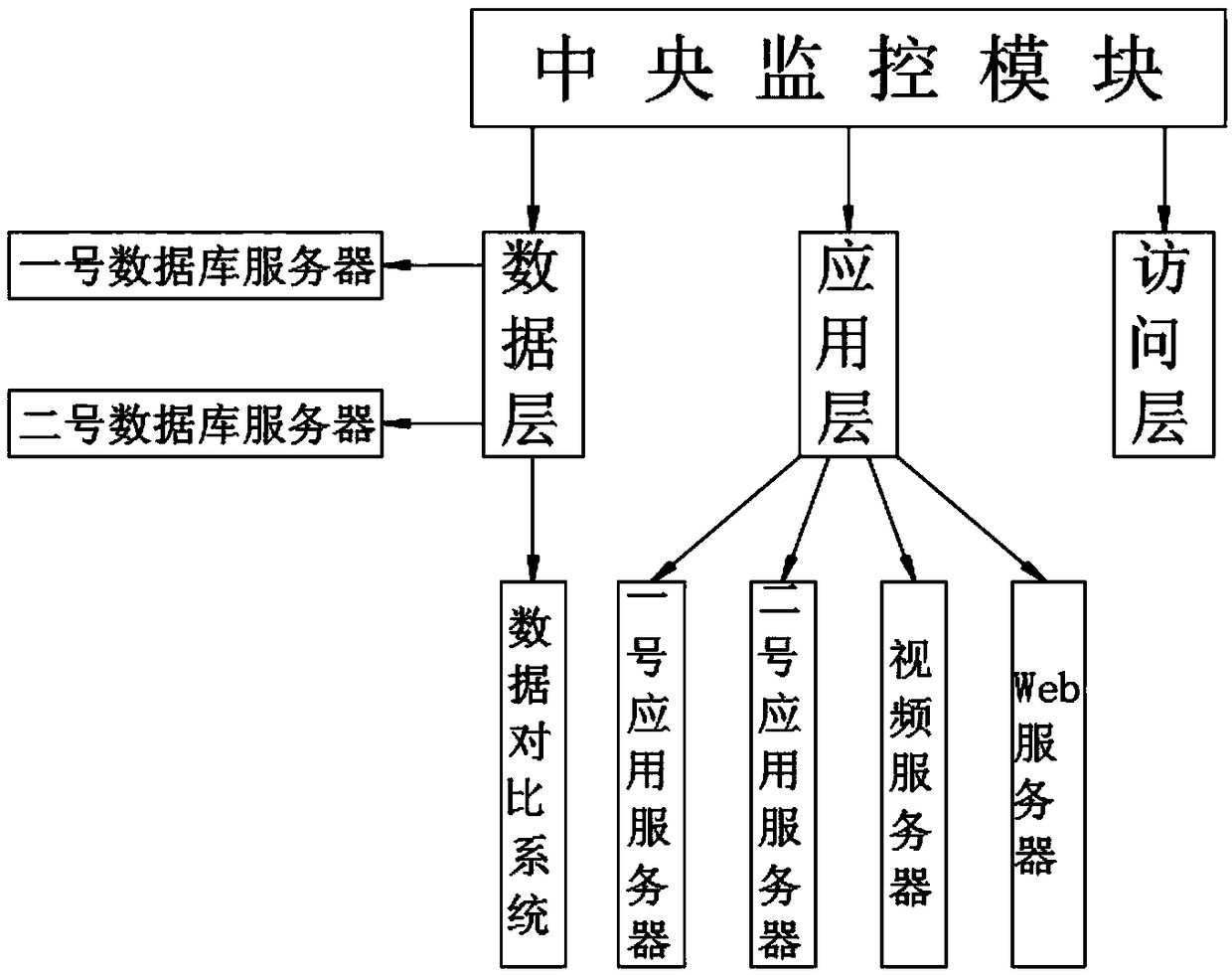

[0022] Example: such as figure 1 As shown, the present invention provides a technical solution, an automatic metering system for wells based on WiFi, which includes a load weighing template of a scraper, a signal identification module, a signal transmission module and a central monitoring module.

[0023] According to the above technical scheme, the load weighing template of the scraper includes a fixed height sensor, an oil pressure sensor, an equipment box and an electronic scale. The fixed height sensor is for judgment and speed measurement, the oil pressure sensor is for weighing and compensation, and the equipment box is In order to transmit data signals, electronic scales are used to receive signals, display data and set values.

[0024] According to the above technical scheme, the oil pressure sensor measures the sampling oil pressure difference between the oil inlet pipe and the oil return pipe when the scraper lifts the hydraulic pressure, and then uses the mathematic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com