Multi-piece piston for active cylinders and active cylinder unit

An active cylinder, multi-piece technology, applied in the directions of pistons, cylindrical pistons, engine components, etc., can solve the problems of small stiffness/strength, high cost, manufacturing trouble, etc., and achieve the effect of improving sealing reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

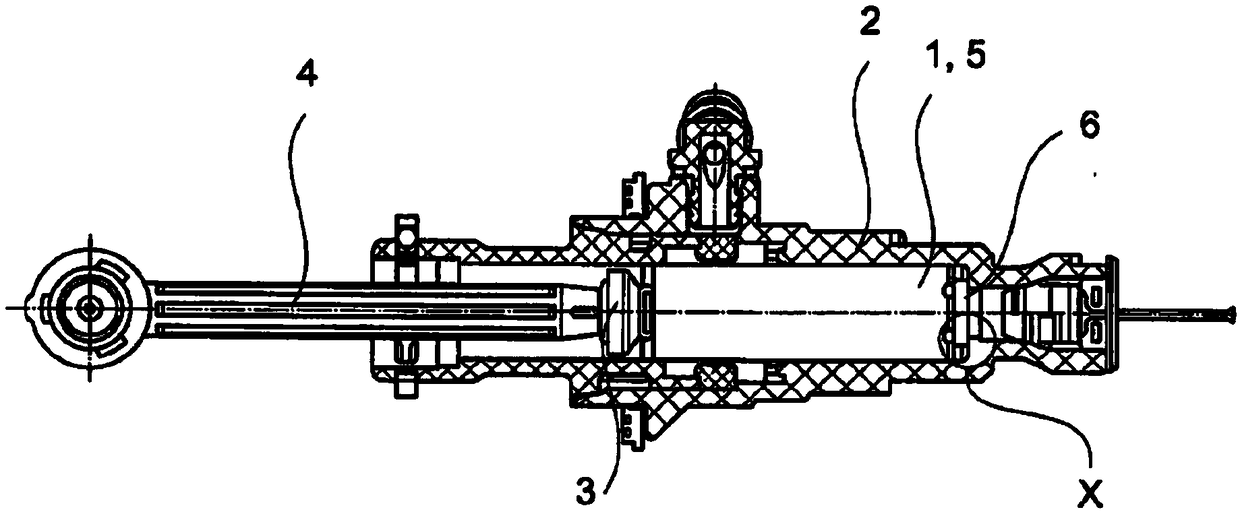

[0059] figure 1 A piston 1 is shown, which is arranged in a hydraulic master cylinder 2 . The piston 1 is coupled to a piston rod 4 via a piston rod receptacle 3 . Furthermore, the piston 1 is constructed in multiple parts such that a guide sleeve 5 for sliding contact with the master cylinder 2 surrounds a core 6 which is independent of the guide sleeve 5 . The circle indicated by the X is further explained below Figure 10 shown in detail.

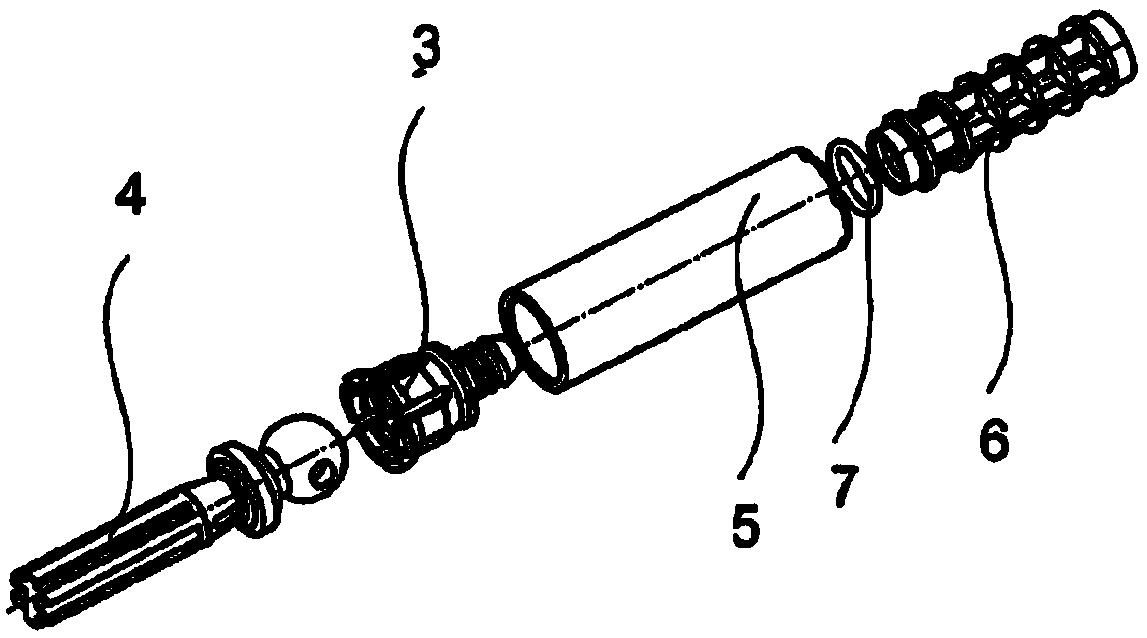

[0060] exist Figure 2a A first embodiment of the piston 1 and the piston rod 4 is shown in an exploded view. An O-ring 7 is arranged as a seal on the end of the core 6 facing the piston rod receptacle 3 . The piston rod receiver 3 has a fir-like structure in order to achieve radial expansion around the ball head of the piston rod 4 .

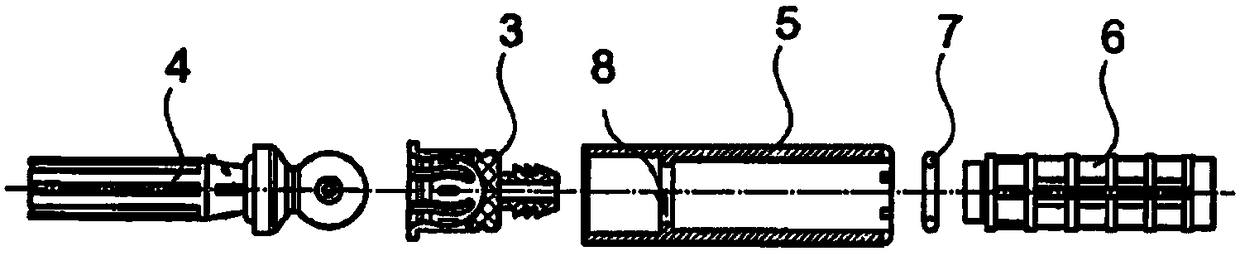

[0061] exist Figure 2b As can be seen in the longitudinal section shown in , the guide sleeve 5 is substantially cylindrical. The sleeve shoulder 8 protrudes towards the axis of rotation of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com