A kind of SF6 electrical equipment on-line gas supply method

A kind of electrical equipment, SF6 technology, applied in the field of SF6 electrical equipment online gas supply, can solve the problems of inability to cut off power at any time, difficulty in ensuring electrical safety, high cost, etc., achieve intelligence and automation, solve electrical safety problems, and reduce manpower requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

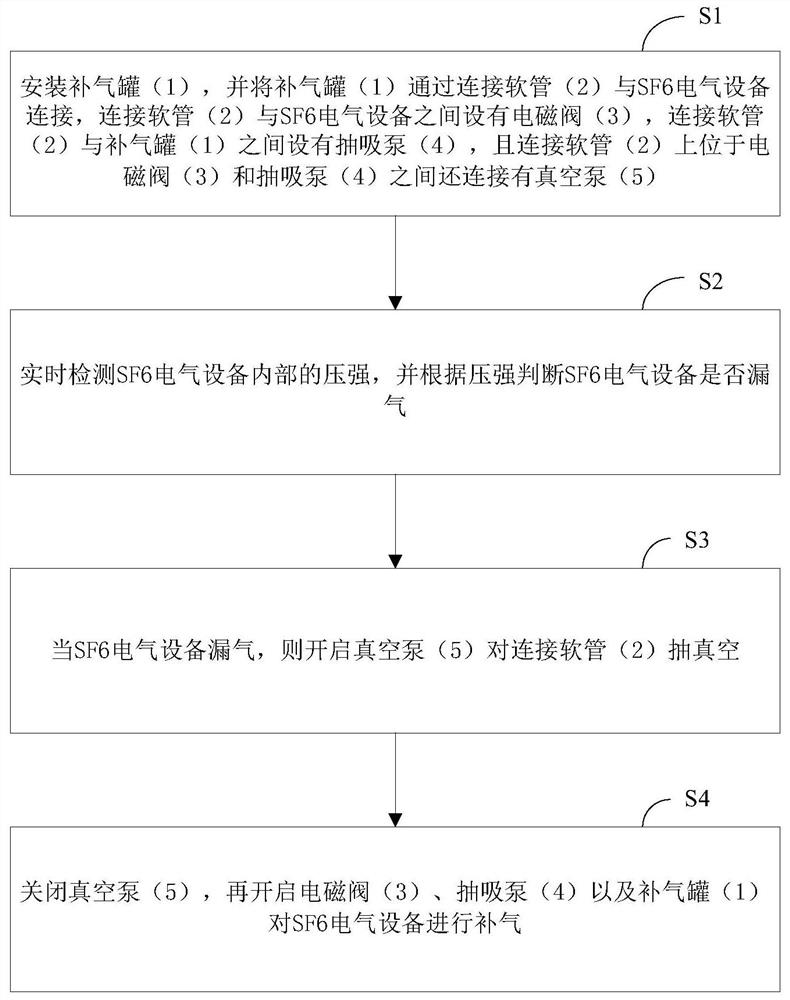

[0028] refer to figure 1 , a kind of SF that the present invention proposes Online method for replenishing gas of electric equipment, comprises the following steps:

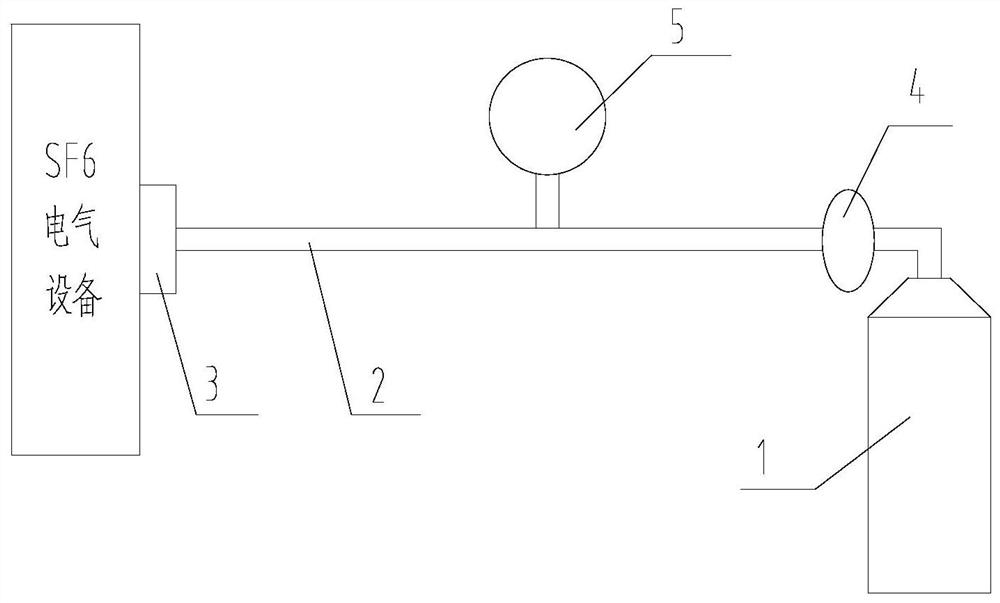

[0029] S1. Install the air supply tank 1, and connect the air supply tank 1 with the SF6 electrical equipment through the connecting hose 2. There is a solenoid valve 3 between the connecting hose 2 and the SF6 electrical equipment, and the connecting hose 2 and the air supply tank 1 A suction pump 4 is arranged between them, and a vacuum pump 5 is also connected between the solenoid valve 3 and the suction pump 4 on the connecting hose 2 . In this way, in this embodiment, the SF6 electrical equipment can be automatically replenished with air through the suction pump 4 and the air supply tank 1 .

[0030] S2. Detect the pressure inside the SF6 electrical equipment in real time, and judge whether the SF6 electrical equipment is leaking according to the pressure. Specifically, in this step, the detected pressure ...

Embodiment 2

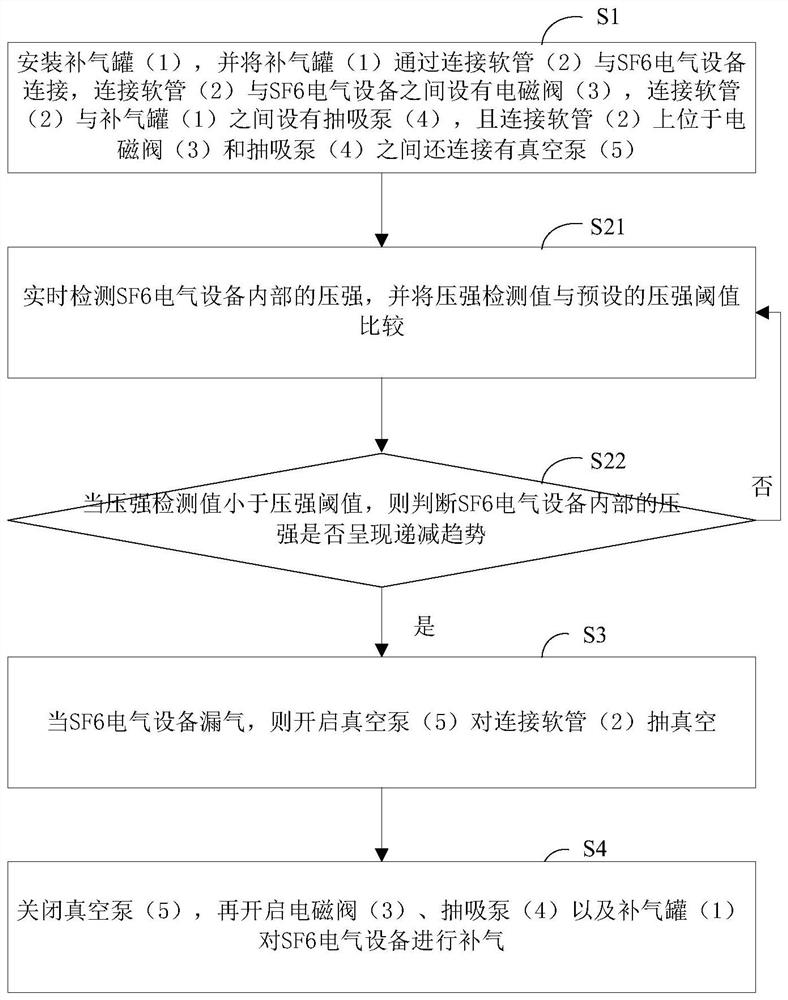

[0037] In this embodiment, step S2 in Embodiment 1 is divided into the following steps.

[0038] S21. Detect the pressure inside the SF6 electrical equipment in real time, and compare the detected pressure value with a preset pressure threshold.

[0039] S22. When the pressure detection value is less than the pressure threshold, it is judged whether the pressure inside the SF6 electrical equipment presents a decreasing trend. If yes, it is judged that the SF6 electrical equipment is leaking. If not, return to step S21. Specifically, in this step, it is judged whether the pressure inside the SF6 electrical equipment is decreasing according to the change trend of the pressure detection value in the SF6 electrical equipment.

[0040] In this way, in this embodiment, in combination with the comparison result of the current pressure detection value and the pressure threshold value and the pressure change trend of the SF6 electrical equipment to determine whether the SF6 electrica...

Embodiment 3

[0043] This embodiment is technically long in Embodiment 2, and step S4 specifically includes the following steps:

[0044] S41. Calculate the leakage flow rate of the SF6 electrical equipment according to the latest N pressure detection values and the gas volume in the SF6 electrical equipment. Specifically, in this step, the latest N pressure detection values are updated in real time, and the leakage flow rate is updated along with the update of the N pressure detection values.

[0045] S42. Adjust the working state of the suction pump 4, and supply air to the SF6 electrical equipment at the same flow rate as the leaked gas.

[0046] In this way, in the present embodiment, gas supplementation is carried out according to the leakage flow rate. On the one hand, it can ensure that the insulating gas pressure in the SF6 electrical equipment is maintained at a safe and stable level; The incoming leakage flow rate is increased, thereby avoiding the excessive waste of insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com