Metal sample polishing and clamping device and manufacturing method thereof

A clamping device and metal sample technology, which is applied in the field of surface grinding treatment, can solve the problems of easily hurting fingers, falling down, flying out of samples, etc., and achieves the effect of low cost, good use effect and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

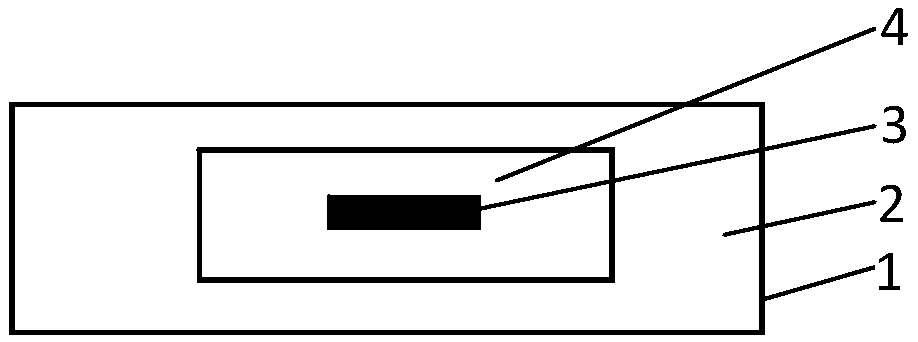

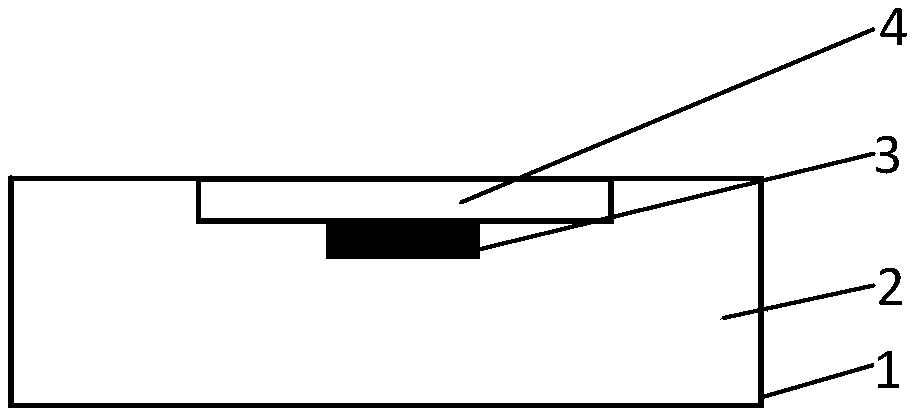

[0028] Take the surface grinding of coupon samples commonly used in corrosion tests as an example.

[0029] 1) Place the sample to be ground in the cavity 4 formed by the curable filler, and the magnet 4 at the bottom of the cavity 4 will firmly fix the sample;

[0030] 2) Grinding with the hand-held grinding sample holding device on the sandpaper or the rotary table grinding machine;

[0031] 3) After finishing the grinding on one side, take out the sample with a thin slice or a knife, and change to the other side for grinding.

[0032] The invention solves the clamping problem of the sample in the sample grinding process, makes the sample hold stable and firm, avoids the damage of the staff's fingers in the process of manually grinding the sample, and can also avoid the clamping during the sample grinding process of the automatic rotary table grinder. The injury caused by the flying out of the sample caused by not holding it firmly makes the sample easy to polish, which gre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com