Automatic reaction cup placing and monitoring system and method

A monitoring system and reaction cup technology, applied in the field of medical equipment, can solve the problems of high labor cost and inconvenient maintenance, and achieve the effect of high automation, convenient maintenance and solving the problem of labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

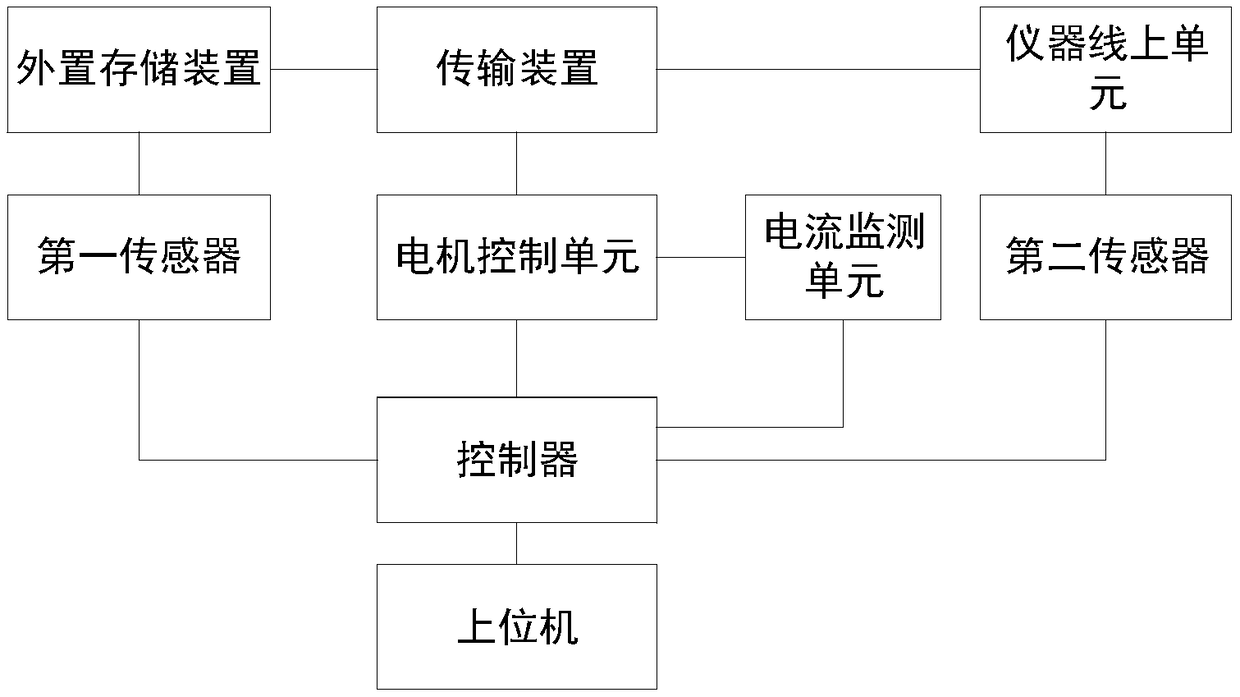

[0041] Such as figure 1 As shown, the embodiment of the present invention provides a cuvette automatic placement and monitoring system suitable for chemiluminescent immunoassay analyzers, including a controller, a host computer, an external storage device, a first sensor, an instrument online unit, a second Sensors, motor control units, transmission devices; where,

[0042] External storage device, first sensor, and controller are sequentially connected; instrument online unit, second sensor, and controller are sequentially connected; controller, motor control unit, and transmission device are sequentially connected; external storage device, transmission device, and instrument line The upper unit is connected sequentially; the controller is also connected with the upper computer;

[0043] Several cuvettes are placed in the external storage device;

[0044] The first sensor monitors the number of cuvettes in the external storage device and sends it to the controller;

[0045...

specific Embodiment 2

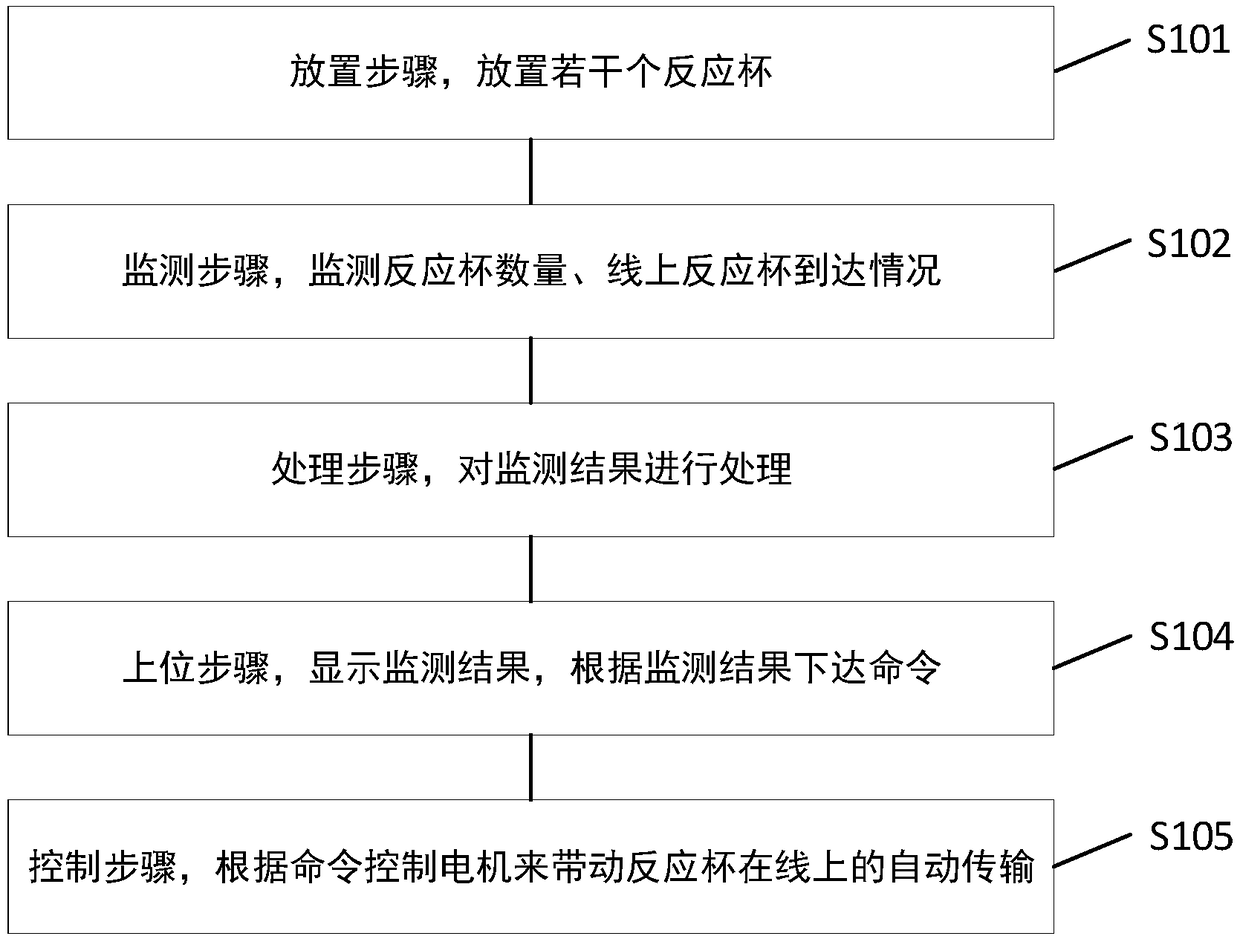

[0061] Such as figure 2 As shown, the embodiment of the present invention also provides a cuvette automatic placement and monitoring method suitable for a chemiluminescence immunoassay analyzer, including:

[0062] Place step S101, place several cuvettes;

[0063] Monitoring step S102, monitoring the number of cuvettes and the arrival of online cuvettes;

[0064] Processing step S103, processing the monitoring result;

[0065] Host step S104, displaying the monitoring result, and issuing an order according to the monitoring result;

[0066] Control step S105, controlling the motor according to the command to drive the automatic transmission of the cuvette on the line.

[0067] The embodiment of the present invention monitors the number of cuvettes in real time, the transmission status of the cuvettes from the external storage device to the line and gives an alarm, and controls the motor to automatically transfer the cuvettes in the external storage device to the line. The...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap