A heat consumption analysis method of cement kiln system combining data-driven and data mining

A data mining and data-driven technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of single consideration or angle, analysis, energy saving space reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0104] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0105] In the prior art, the fuzzy PID algorithm is used to design the controller, its anti-interference ability is weak, the stabilization time is relatively long, and the control accuracy is not high enough;

[0106] In the existing technology, the principle of mechanism modeling is used to establish a mathematical model, and then to perform predictive control, which can only analyze a part but not the entire kiln system.

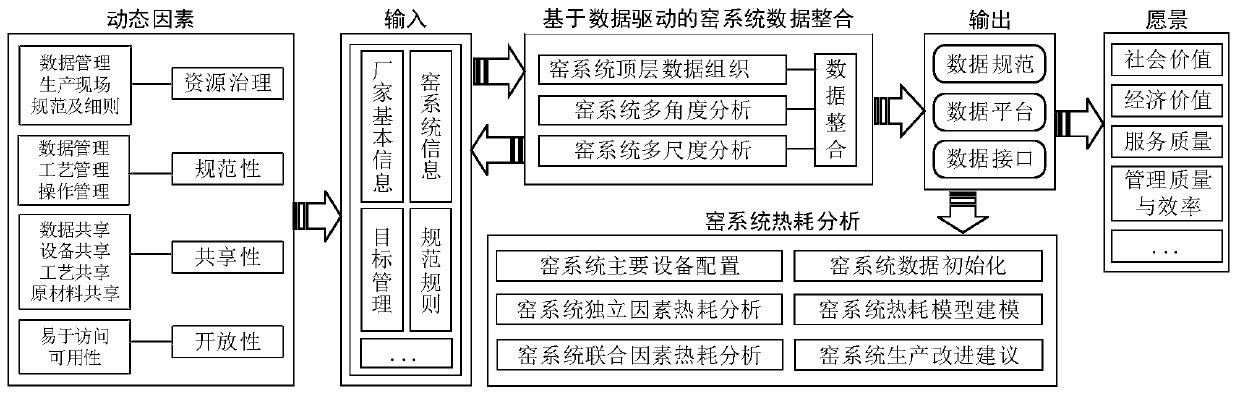

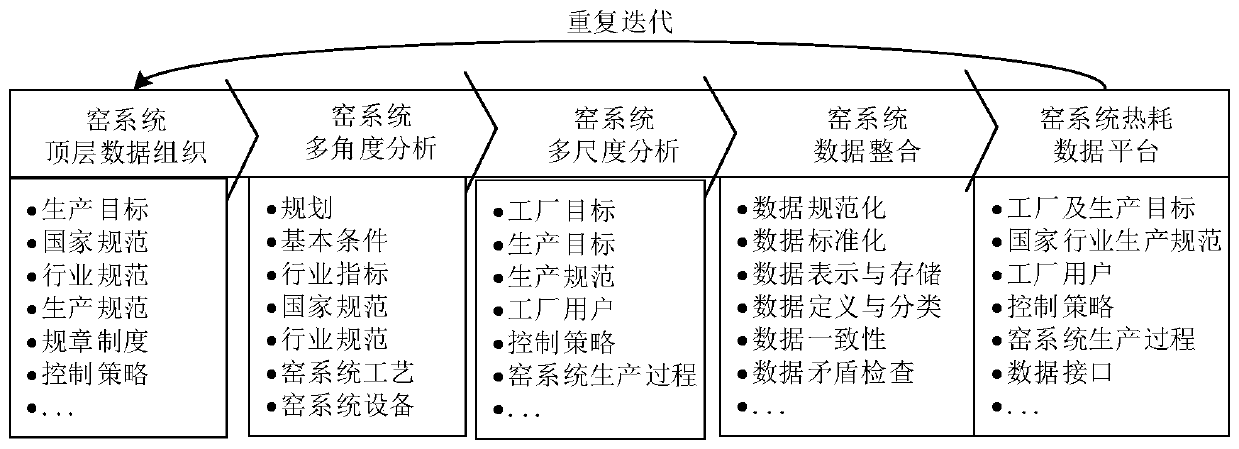

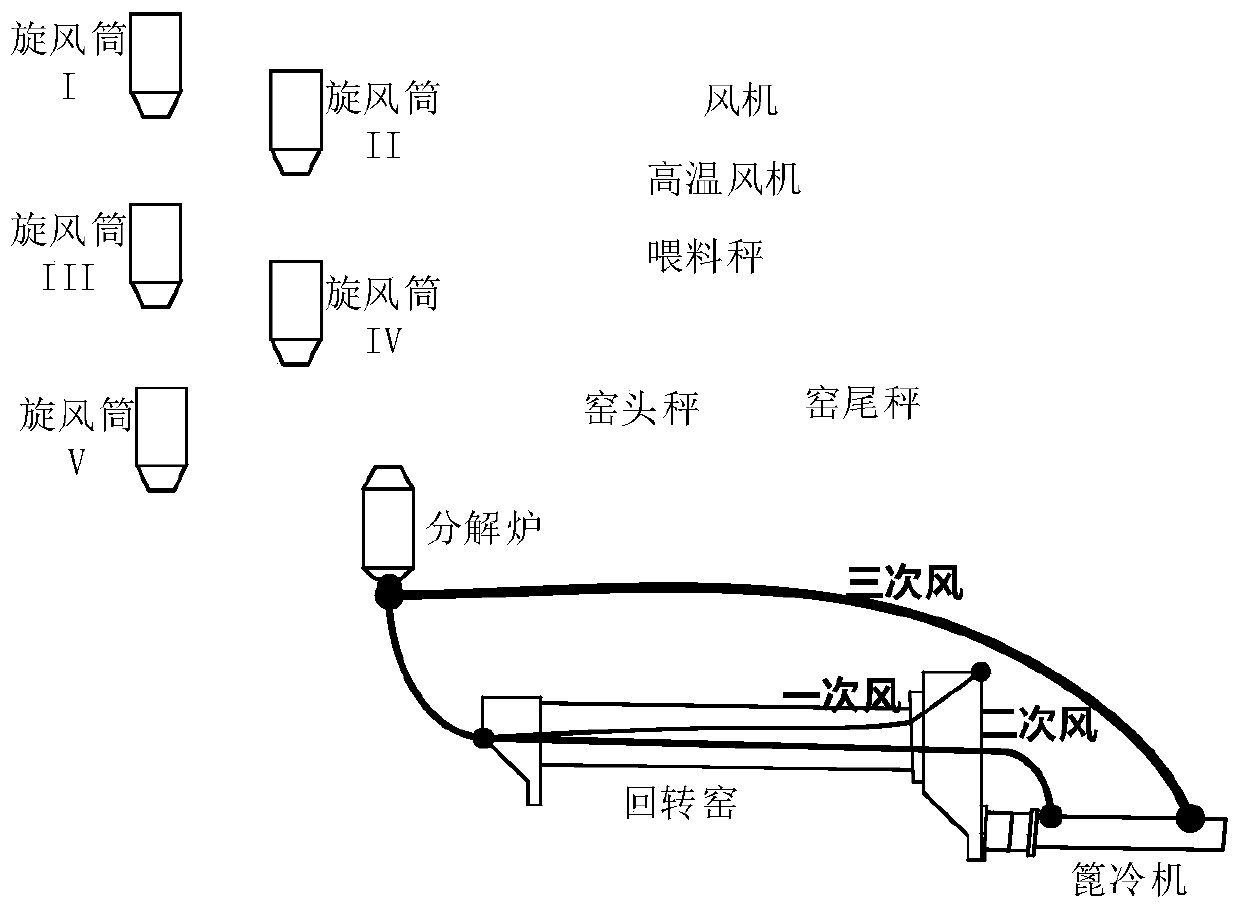

[0107] The cement kiln system heat consumption analysis method combined with data-driven and data mining provided by the embodiment of the present invention includes:

[0108] Using data mining and mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com