A low-profile CTS plate array antenna

一种阵列天线、低剖面的技术,应用在天线、隙缝天线、天线阵列等方向,能够解决偏置抛物反射面加工要求高、装配要求过程复杂、装配要求高等问题,达到结构设计紧凑、实现剖面的设计、降低加工难度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

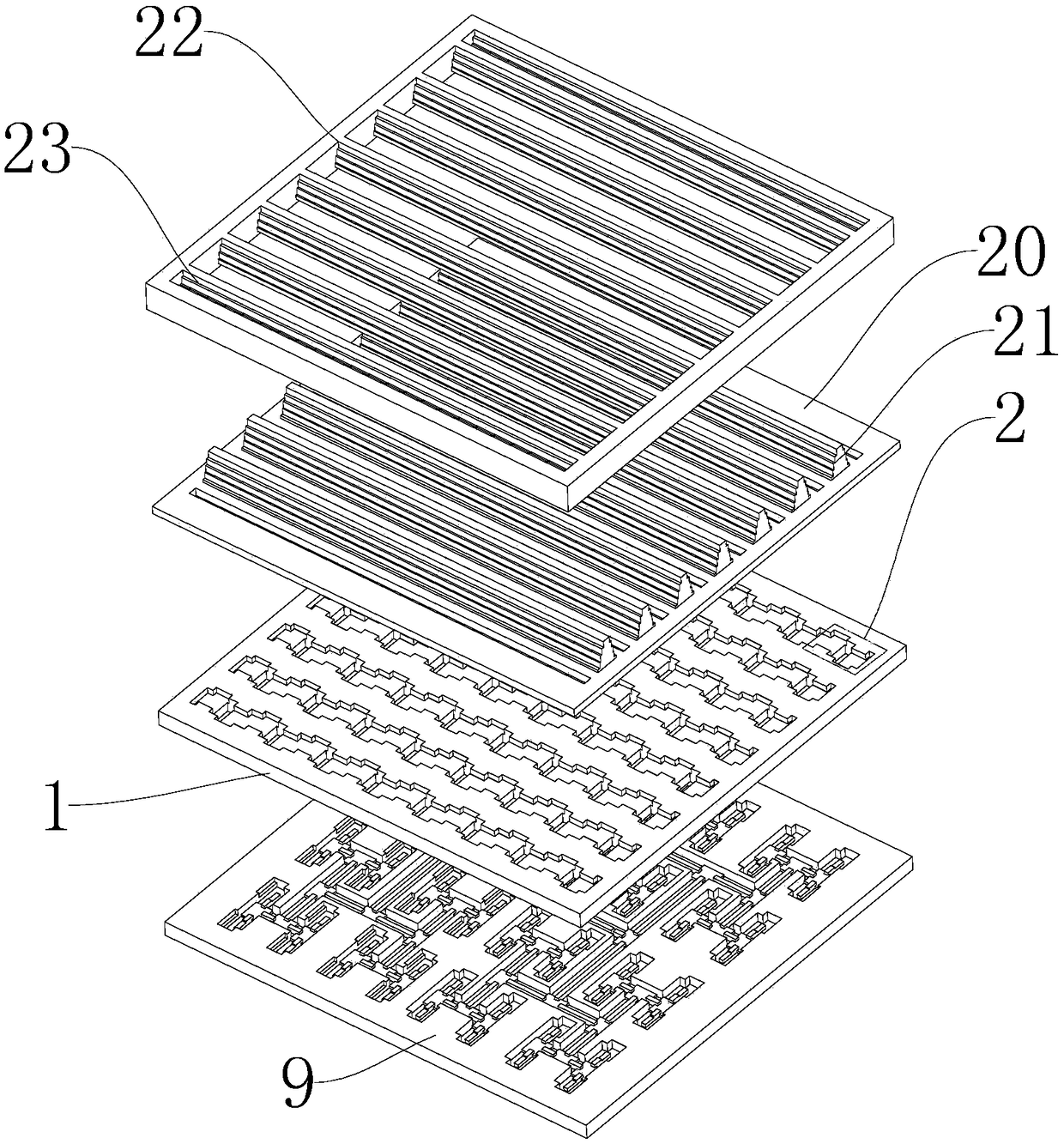

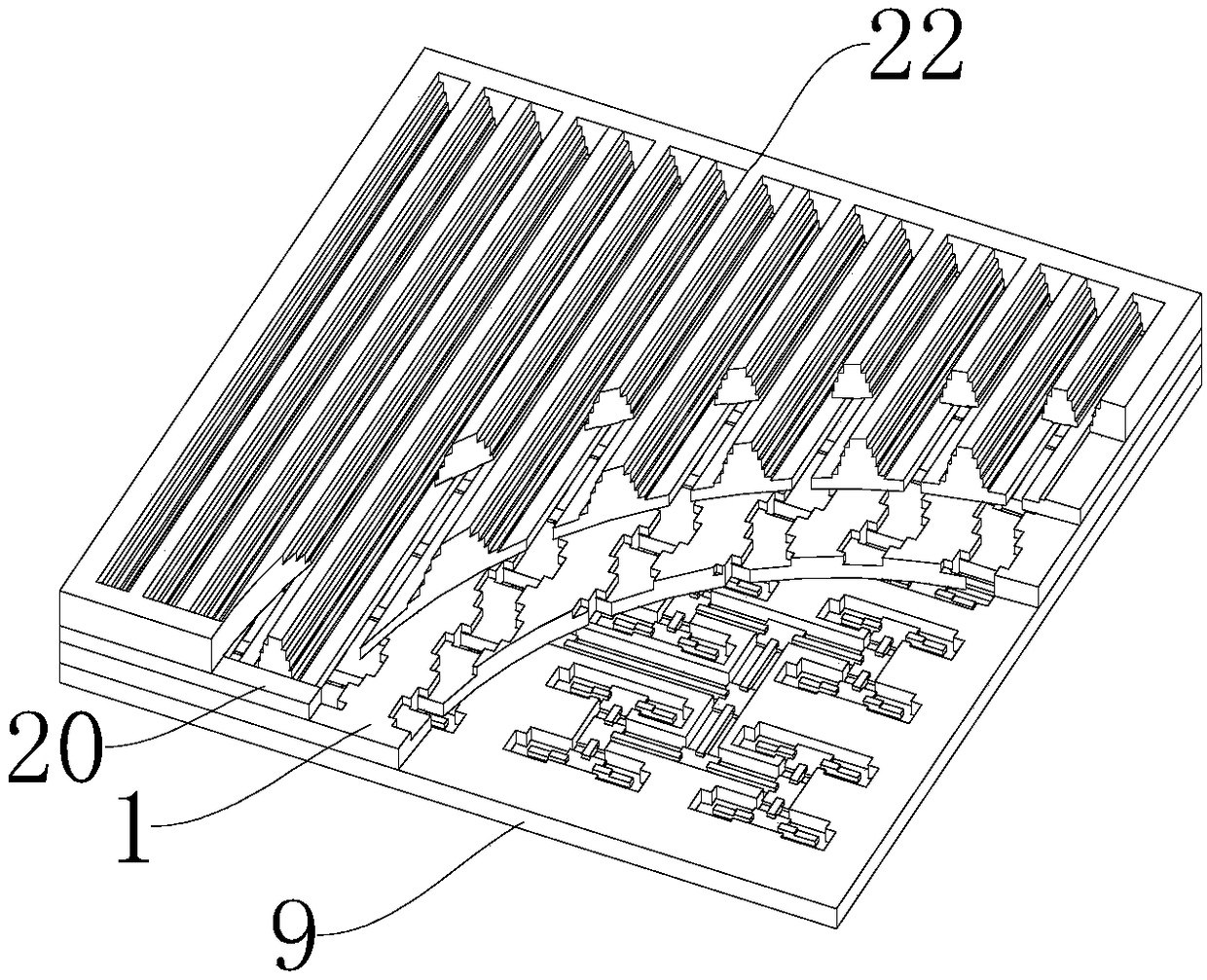

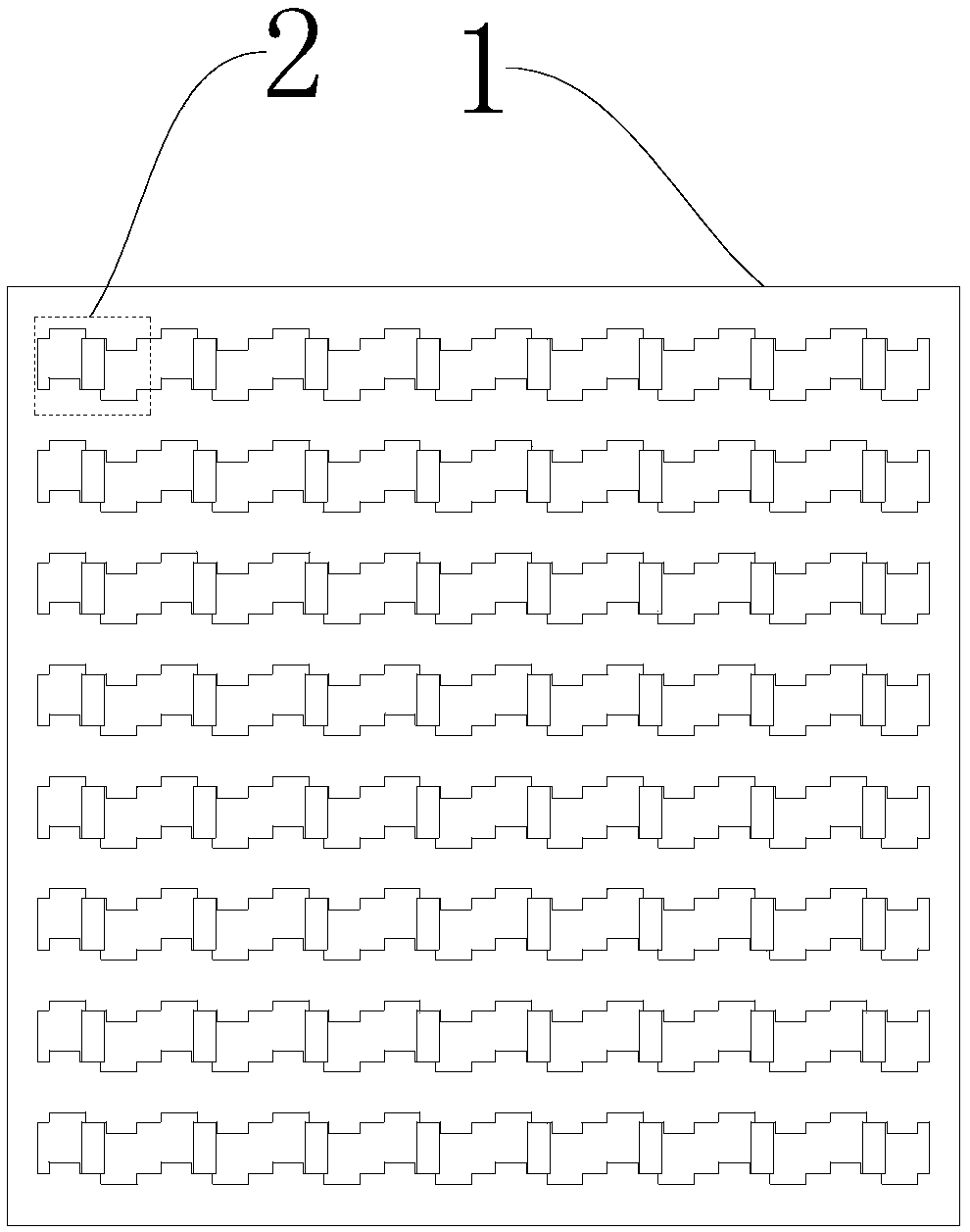

[0020] Embodiment: As shown in the figure, a low-profile CTS planar array antenna includes a radiation layer, a mode conversion layer, and a feed network layer arranged in sequence from top to bottom. The mode conversion layer includes a first metal plate 1 and a second A mode conversion cavity array on the upper surface of a metal plate 1, the mode conversion cavity array includes 2 2n mode conversion cavities 2, 2 2n mode conversion cavity 2 in accordance with 2 n row x 2 n Arranged in columns, n is an integer greater than or equal to 1, and 2 in the same row n The three mode conversion cavities 2 are connected end to end in sequence; the mode conversion cavity 2 includes a first rectangular cavity 3, a second rectangular cavity 4, a third rectangular cavity 5, a fourth rectangular cavity 6 and a fifth rectangular cavity 7 connected in sequence from left to right , the row direction of the long edge mode conversion cavity array of the first rectangular cavity 3, the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com