A heat-dissipating strip of a PTC heat-sensitive material heat-dissipating device and a manufacturing method and use thereof

A technology for heating devices and heat-sensitive materials, applied in the direction of heating element materials, heating element shapes, ohmic resistance heating parts, etc. Improve comfort and environmental protection functions, improve heat dissipation area and heat, and improve the effect of the use environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

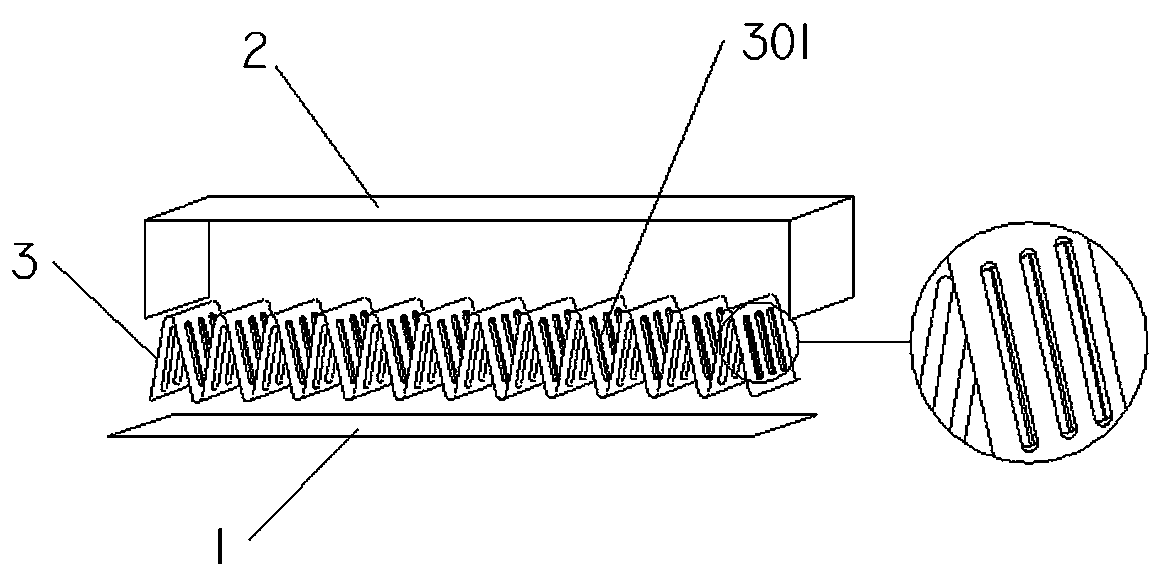

[0050] Such as figure 1 The heat dissipation strip of the PTC heat-sensitive material heating device shown includes a heat dissipation corrugation 3 clamped by a heat conduction flat sheet 1 and a folded edge positioning heat conduction sheet 2, and the heat dissipation corrugation 3 has a height direction of not less than A semi-arc concave surface 301, the concave surface 301 is perpendicular to the width direction of the heat dissipation strip.

Embodiment 2

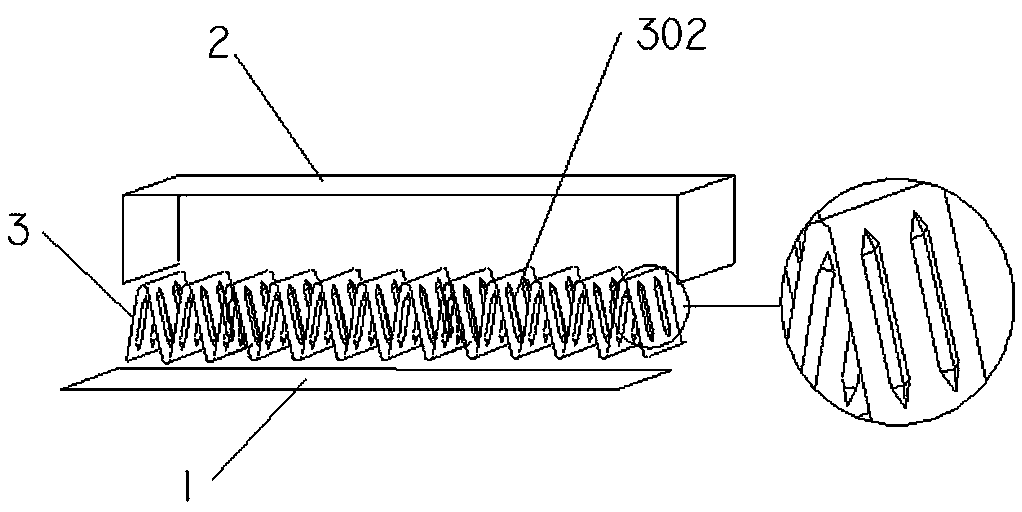

[0052] Such as figure 2 As shown, referring to Embodiment 1, the heat dissipation corrugations 3 have not less than one angled surface 302 along the height direction of the heat dissipation surface, and the angled surface 302 is perpendicular to the width direction of the heat dissipation strip.

Embodiment 3

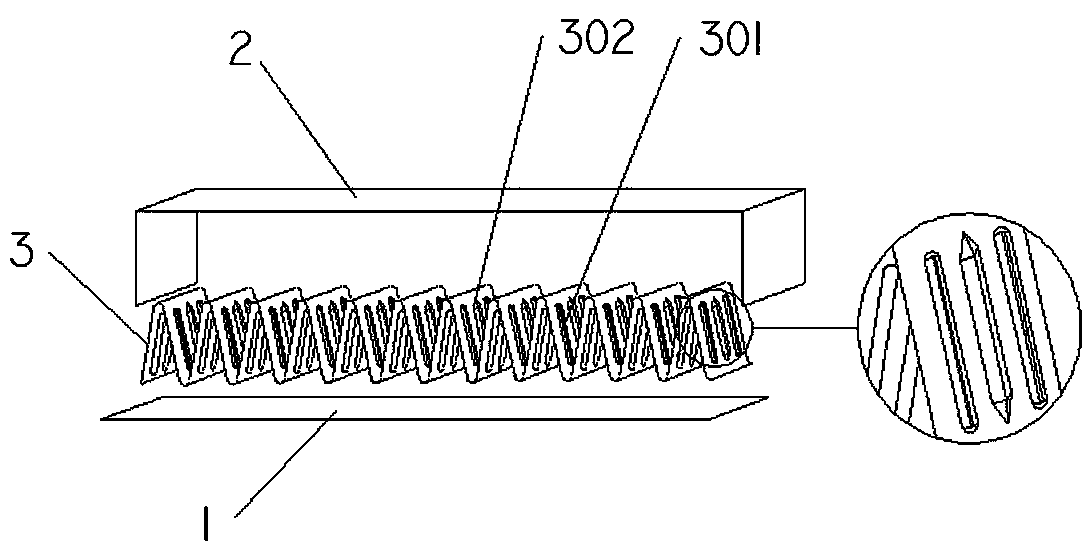

[0054] Such as image 3 As shown, referring to Embodiments 1 and 2, the height direction of the heat dissipation corrugation 3 has a concave surface 301 and a fan-folded surface 302 at the same time, and the concave surface 301 and the angled surface 302 are perpendicular to the width direction of the heat dissipation strip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com