Distributed Server Liquid Cooling System

A distributed server and liquid cooling technology, applied in the field of server heat exchange, can solve problems such as limited space, large occupied space, and huge system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

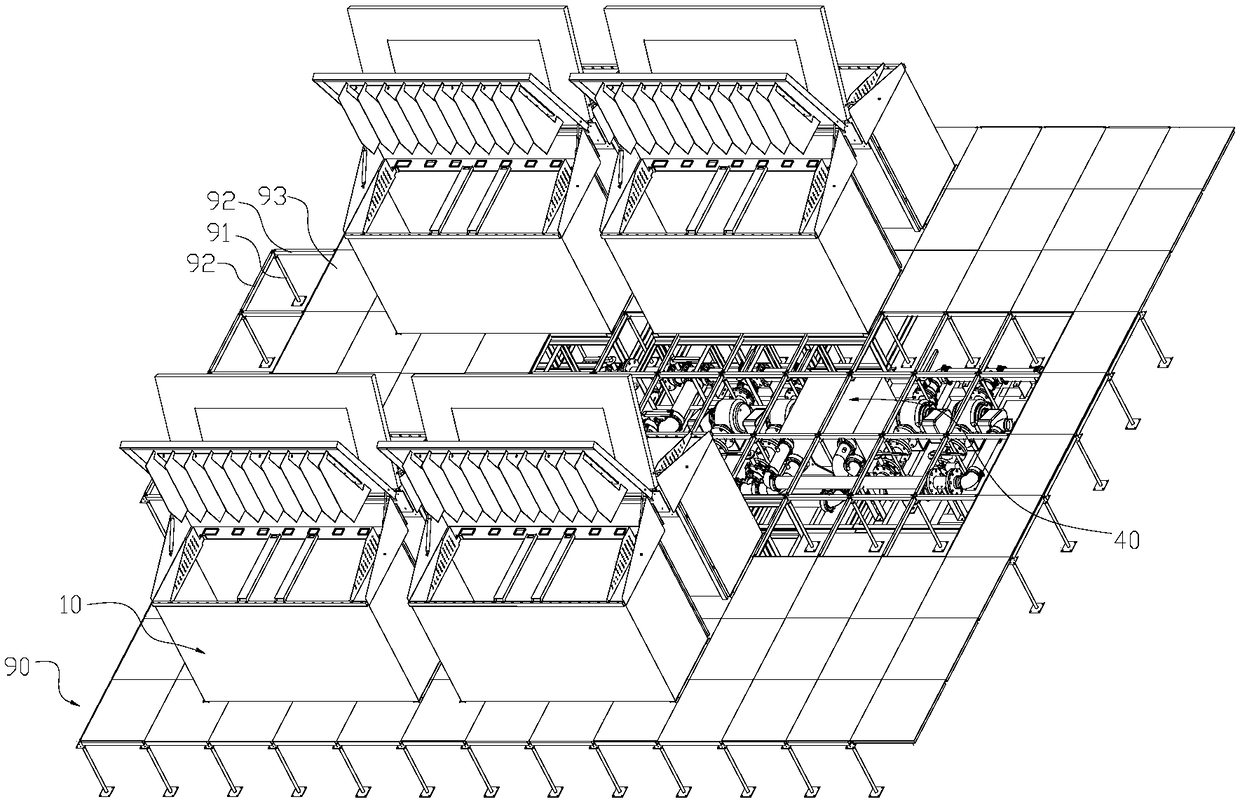

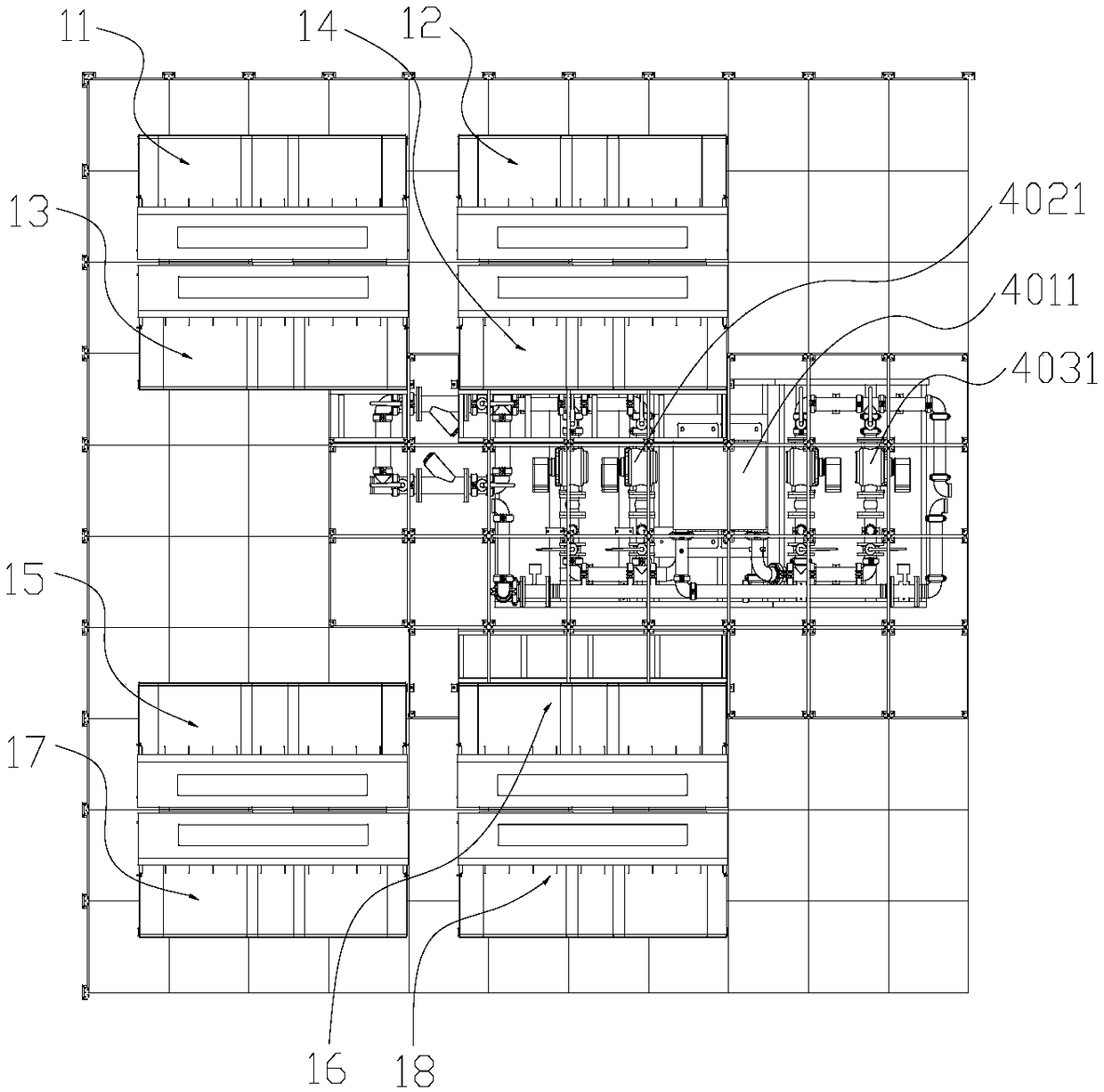

[0088] Example 1, such as figure 1 , figure 2 , image 3 As shown in the standard 8-cabinet distributed server liquid cooling system, the distributed server liquid cooling system hosts are arranged horizontally along the passage side of the aisle in the middle aisle area of the two sets of distributed server liquid cooling system cabinets. This layout can be reserved Increase the installation area of the cabinets of the distributed server liquid cooling system. At the same time, core components such as filters, pumps, and heat exchangers that may need to be maintained or replaced frequently are placed under the static floor of the aisle for easy maintenance.

Embodiment 2

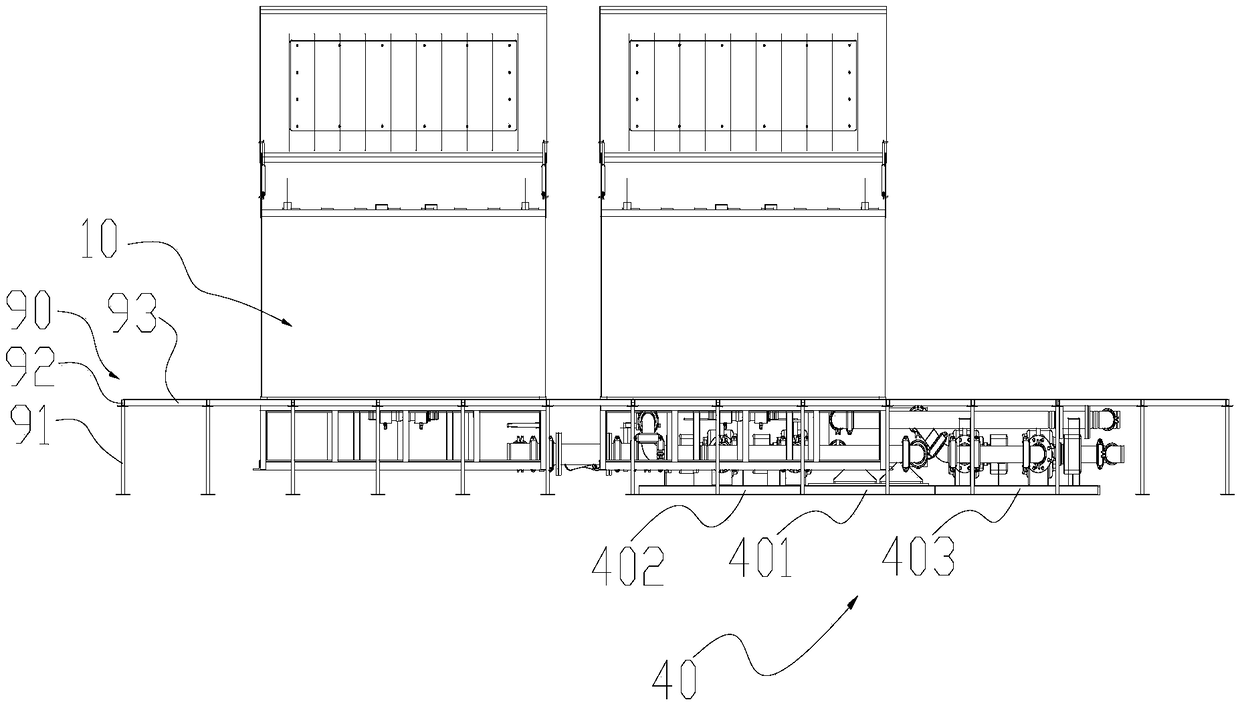

[0089] Example 2, such as Figure 8 , Figure 9 , Figure 10 As shown, in the standard 4-cabinet distributed server liquid cooling system, the distributed server liquid cooling system mainframe is longitudinally arranged in the middle aisle area of the two sets of distributed server liquid cooling system cabinets along the vertical direction of the passing side of the aisle. This layout method Wider aisles can be reserved. The installation area available for liquid-cooled server cabinets will be slightly reduced. At the same time, core components such as filters, pumps, and heat exchangers that may require frequent maintenance or replacement are placed under the static floor of the aisle for easy maintenance. The first refrigerant liquid outlet and liquid return port are arranged directly under the electrostatic floor in the area closest to the cabinet liquid inlet and cabinet liquid outlet of the distributed server liquid cooling system, which can reduce the difficulty of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com