Fluidized bed cluster reactor

A fluidized bed and reactor technology, applied in the field of gas-solid reaction fluidization equipment, can solve the problems of not describing the fluidized bed cluster reactor, unable to meet practical application requirements, affecting the gas-solid reaction efficiency, etc., and achieve easy implementation. , Reasonable design, small particle wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

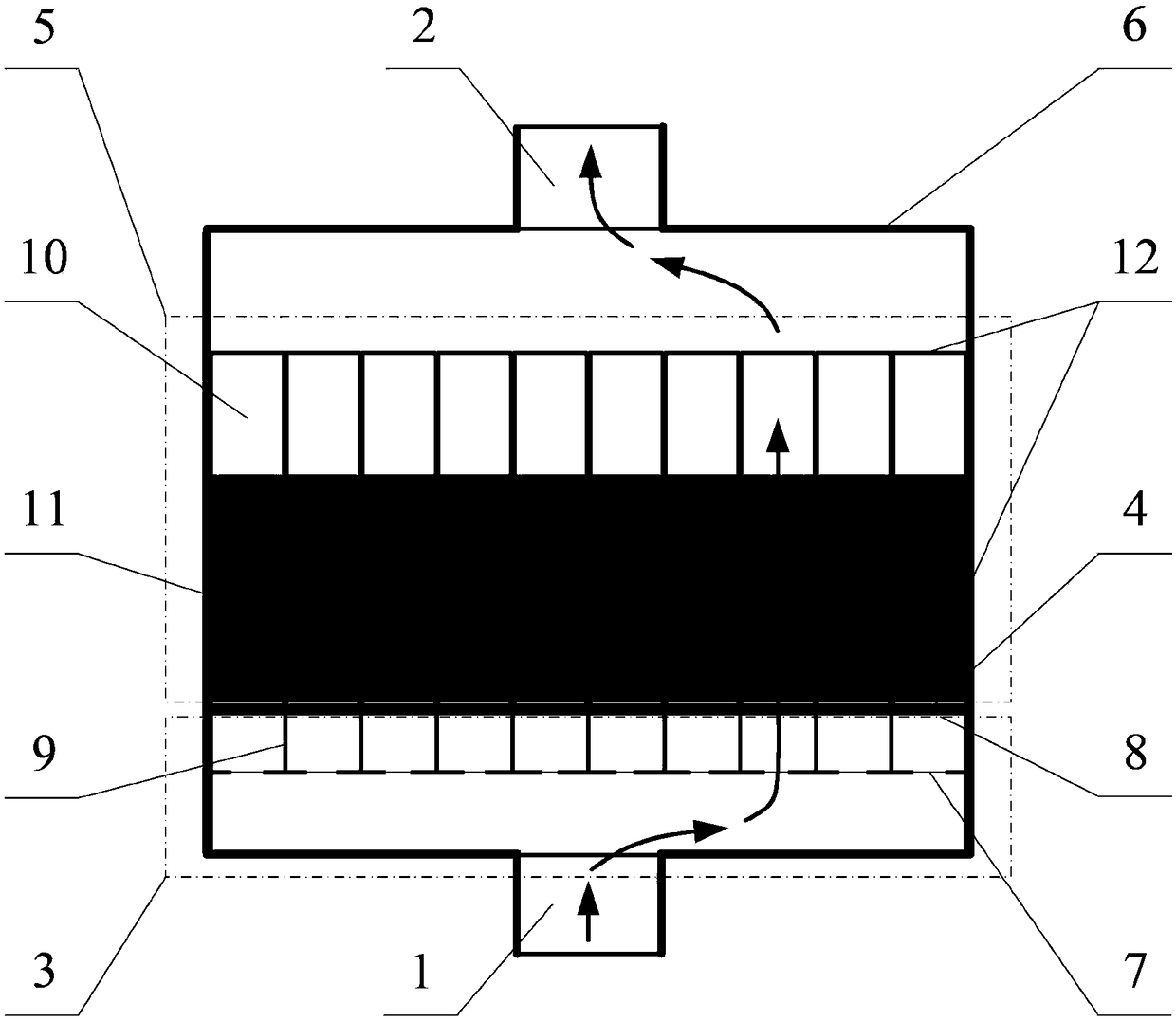

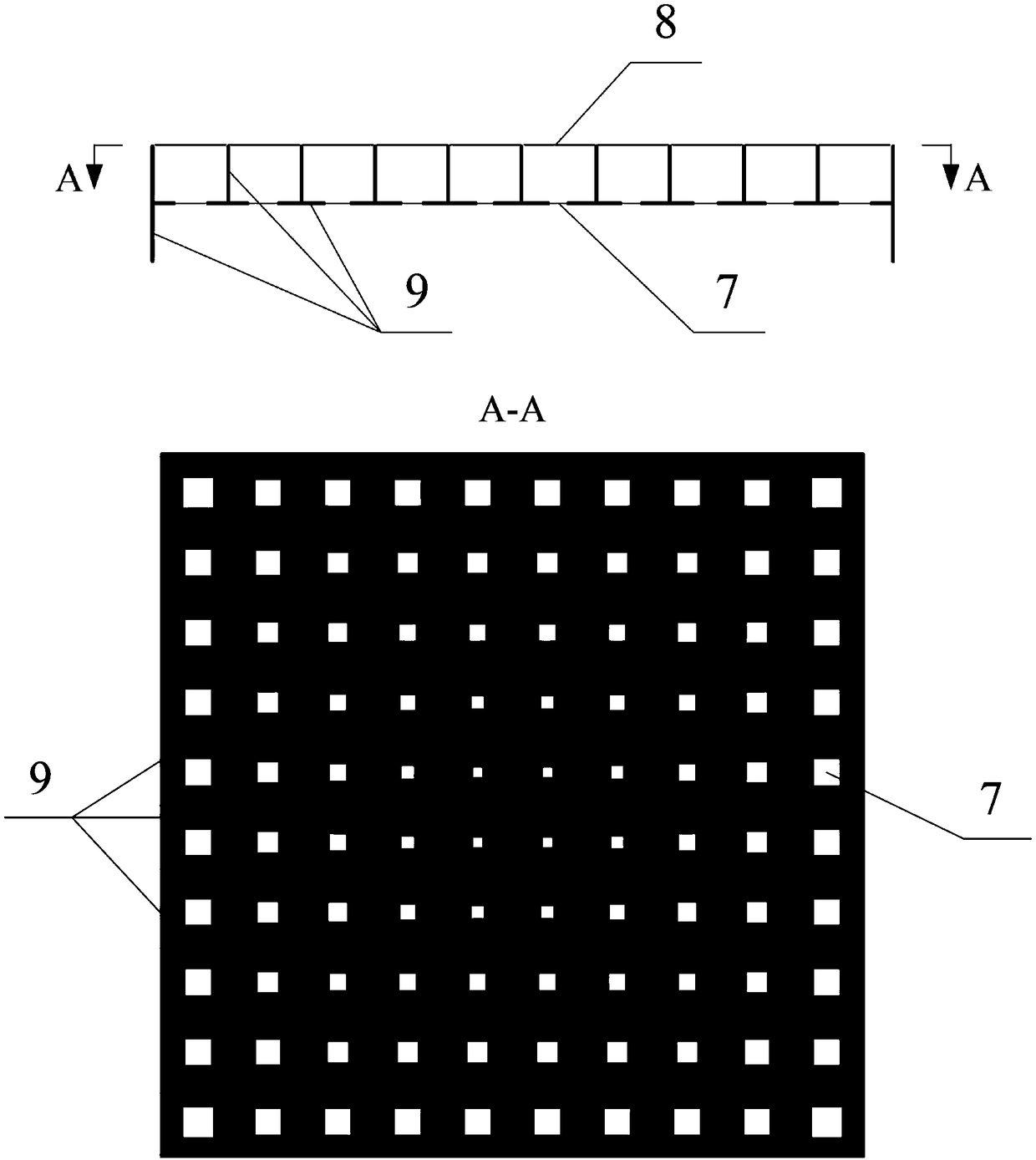

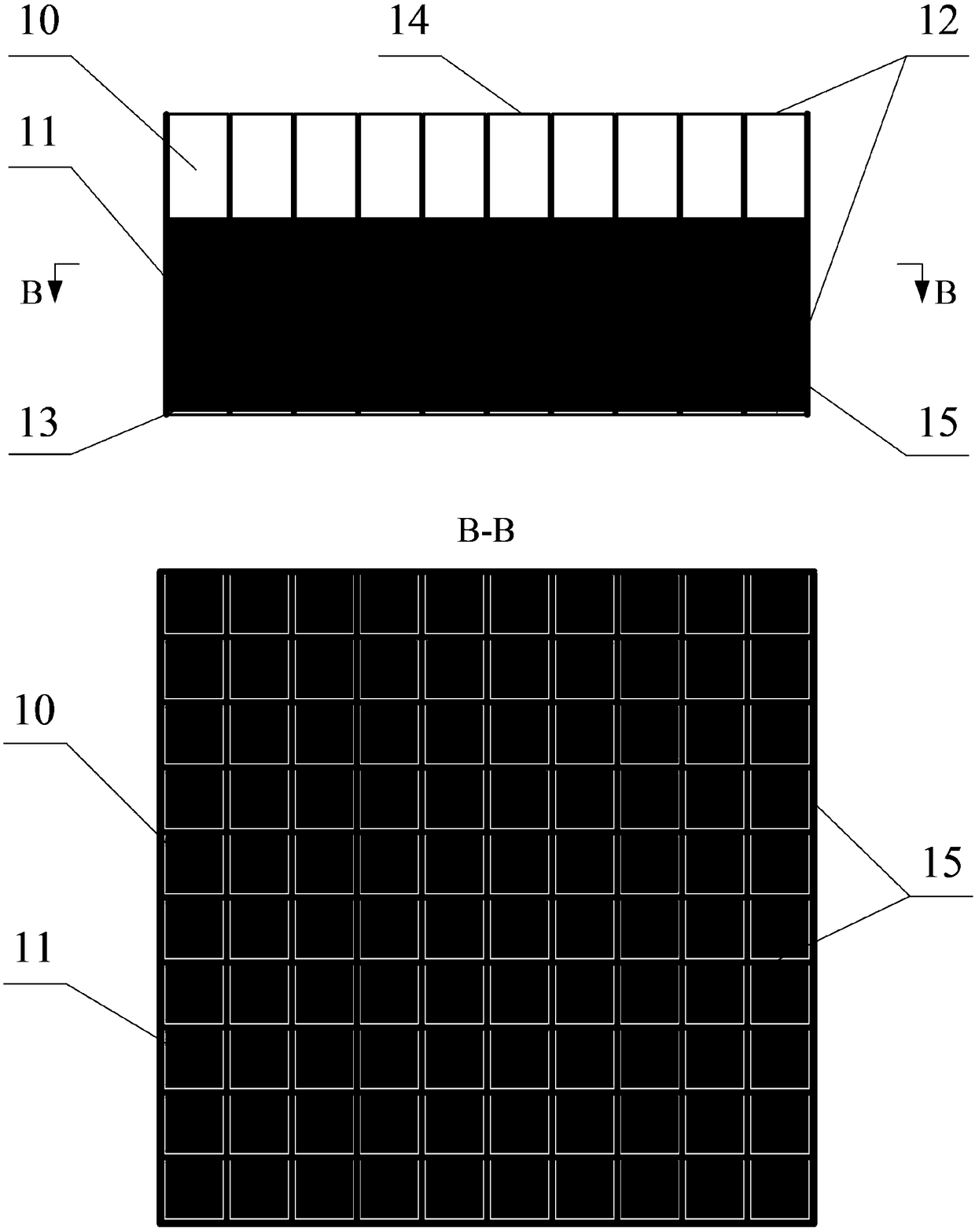

[0031] A fluidized bed cluster reactor, which is composed of an air inlet 1, an air outlet 2, a header 3, an air distribution plate 4, a fluidized bed cluster adsorption bed 5, and a shell 6; the cross section of the shell 6 is square; the inside of the header 3 Air inlet 7, air outlet 8 and manifold wall 9 are provided; the air outlet 8 of manifold 3 is square; the fluidized bed cluster adsorption bed 5 includes several bed pipes 10, granular materials 11 and leak-proof net 12 arranged side by side ; The bed tubes 10 in the fluidized bed cluster adsorption bed 5 are at the same height; the cross-sections of the bed tubes 10 are all square; the centers of the bed tubes 10 are arranged in parallel. The air inlet 1 of the reactor is connected to the header 3, and the header 3 is connected to the inlet 13 of the fluidized bed cluster adsorption bed 5, and the leak-proof net 12 prevents the granular material 11 in the bed pipe 10 from leaking out while ensuring the smooth flow of g...

Embodiment 2

[0033] A fluidized bed cluster reactor, which is composed of an air inlet 1, an air outlet 2, a header 3, an air distribution plate 4, a fluidized bed cluster adsorption bed 5, and a shell 6; the cross section of the shell 6 is square; the inside of the header 3 Air inlet 7, air outlet 8 and manifold wall 9 are provided; the air outlet 8 of manifold 3 is square; the fluidized bed cluster adsorption bed 5 includes several bed pipes 10, granular materials 11 and leak-proof net 12 arranged side by side ; The center of the bed tube 10 in the fluidized bed cluster adsorption bed 5 gradually rises as the distance from the center point of the reactor increases; the cross-sections of the bed tubes 10 are all square; the centers of the bed tubes 10 are arranged in parallel. The air inlet 1 of the reactor is connected to the header 3, and the header 3 is connected to the inlet 13 of the fluidized bed cluster adsorption bed 5, and the leak-proof net 12 prevents the granular material 11 in...

Embodiment 3

[0035] A fluidized bed cluster reactor, which is composed of an air inlet 1, an air outlet 2, a header 3, an air distribution plate 4, a fluidized bed cluster adsorption bed 5, and a shell 6; the cross section of the shell 6 is square; the inside of the header 3 An air inlet 7, an air outlet 8 and a manifold wall 9 are provided; the air outlet 8 of the manifold 3 is a regular hexagon; the fluidized bed cluster adsorption bed 5 includes several bed pipes 10 arranged side by side, granular materials 11 and anti-corrosion The leaking net 12; the bed tubes 10 in the fluidized bed cluster adsorption bed 5 are at the same height; the cross-sections of the bed tubes 10 are regular hexagons; the centers of the bed tubes 10 are arranged in parallel. The air inlet 1 of the reactor is connected to the header 3, and the header 3 is connected to the inlet 13 of the fluidized bed cluster adsorption bed 5, and the leak-proof net 12 prevents the granular material 11 in the bed pipe 10 from lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com