On-line monitoring and troubleshooting assisting system of ball mill

A help system and ball mill technology, applied in grain processing and other directions, can solve the problem of no ball mill online monitoring and fault handling help system, etc., and achieve the effect of good visibility, good human-computer interaction interface, and convenient and timely processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

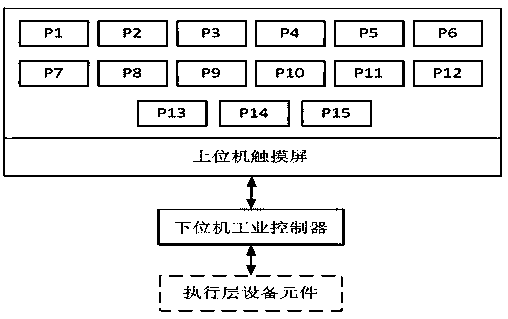

[0031] The present invention is an on-line monitoring and fault handling assistance system for a ball mill. In the assistance system, the touch screen of the upper computer is used as the carrier to write monitoring screens and fault alarm screens. The monitoring screens are switched by clicking the button above the touch screen, through the MPI protocol or Ethernet. The protocol communicates with the PLC of the lower computer, reads PLC data, monitors the ball mill in real time, and provides alarms, fault records, and corresponding cause analysis and processing. It has a good human-computer interaction interface, good visibility, and easy operation. Simple, you can check the running status of each part of the ball mill at any time.

[0032] The help system of the present invention includes a touch screen of an upper computer, an industrial controller of a lower computer, and equipment elements of an execution layer, wherein the industrial controller of the lower computer and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com