Gas turbine component air flow test bench and test method

A technology of air flow and gas turbine, which is applied in the direction of gas turbine engine testing, mechanical component testing, machine/structural component testing, etc. It can solve the problems of large space occupation, time-consuming operation, and low measurement accuracy, so as to improve flow measurement Accuracy, simple composition and structure, good safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

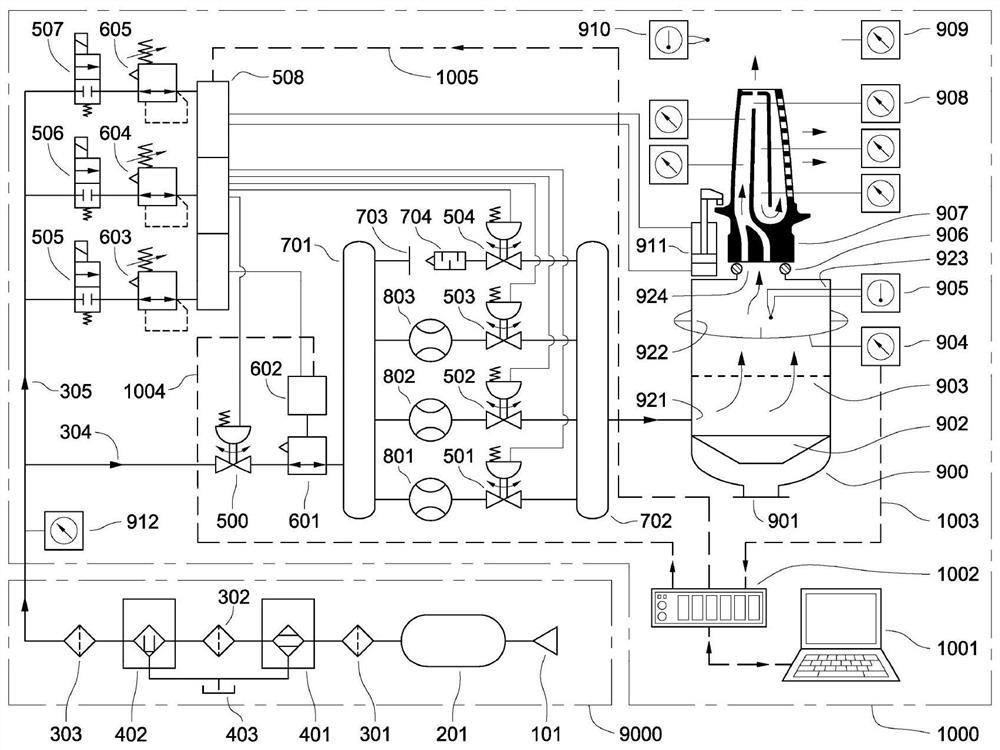

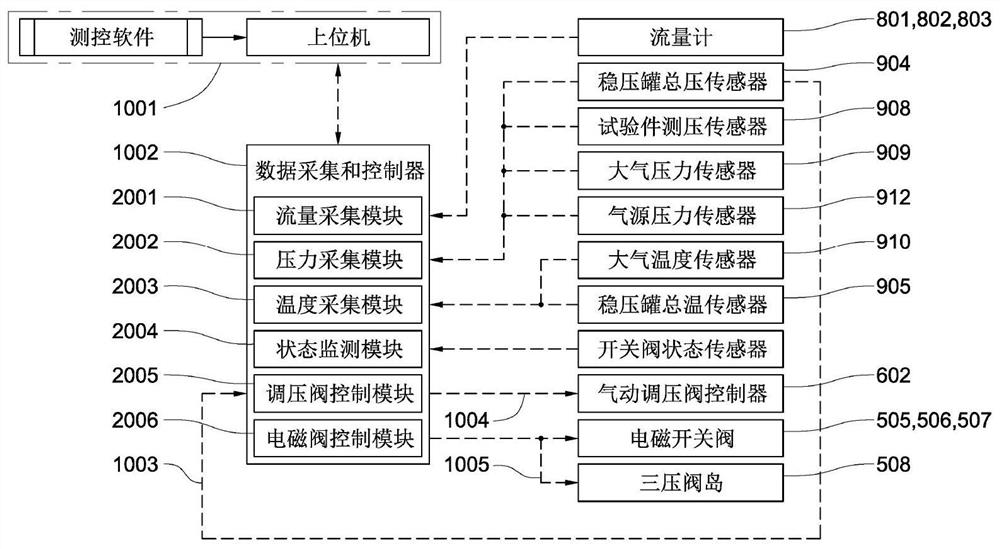

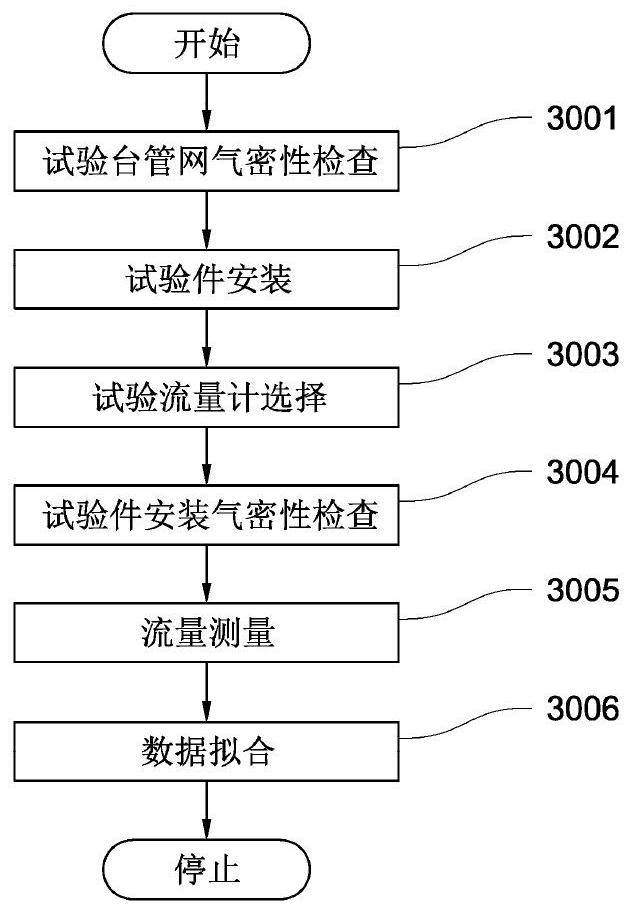

[0065] Such as Figure 1 to Figure 8 The shown air flow test bench for gas turbine components includes air source processing equipment 9000 and a test bench body 1000 .

[0066] The air source treatment equipment 9000 is composed of an air compressor 101, an air storage tank 201, a primary filter 301, a freeze dryer 401, a medium filter 302, an adsorption dryer 402, and a high efficiency filter 303 in series. Wherein, the refrigerated dryer 401 and the adsorption dryer 402 discharge water into the water-repellent device 403 . The filtration accuracy of the primary filter 301 , the intermediate filter 302 , and the high efficiency filter 303 increases step by step, and the filtration accuracy of the outlet of the high efficiency filter 303 is 0.01 μm. The freeze dryer 401 controls the dew point temperature of the processed air at 2°C to 10°C, and the adsorption dryer 402 controls the dew point temperature of the processed air at -20°C to 0°C. After being compressed by the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com