Odor absorption process for sludge press workshop

A technology of sludge squeezing and sludge squeezing machine, which is applied in the direction of dust removal, cleaning methods and appliances, chemical instruments and methods, etc., which can solve the problems of endangering the health of personnel and emitting odor, and achieve the effect of reducing hazards and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0034] The odor absorption process used in the sludge press workshop includes the following steps:

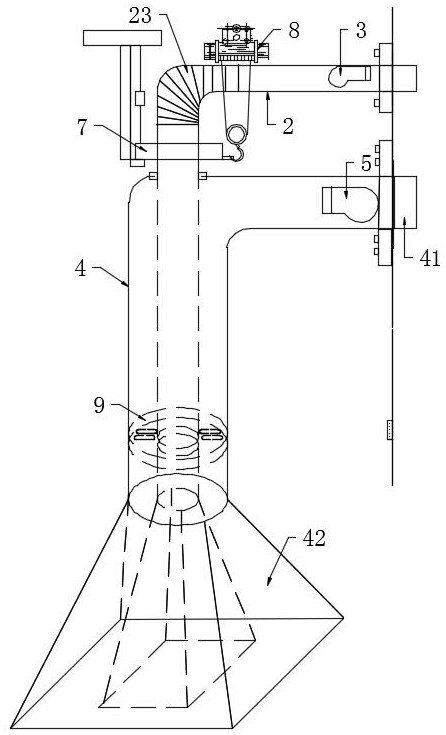

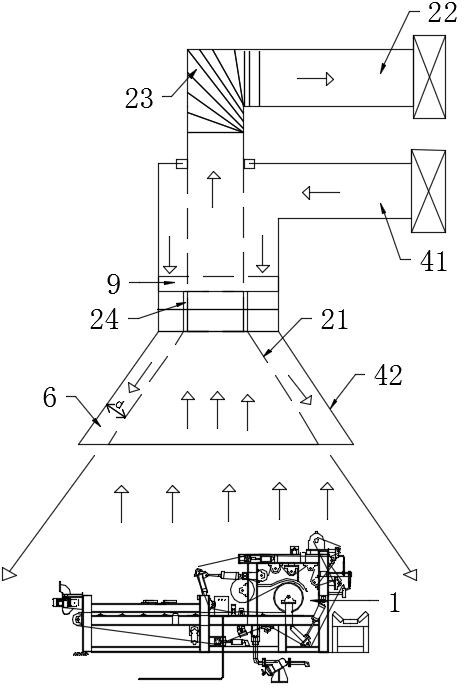

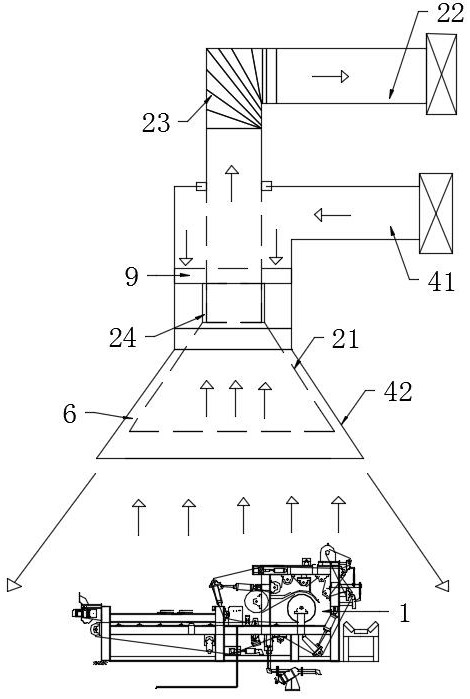

[0035] Isolating the source of the odor, the step of isolating the source of the odor is to use a cover to cover the sludge press 1;

[0036] Suck away the foul smell, the step of sucking the bad smell is to use the exhaust pipe 2 to suck away the bad smell in the cover body, wherein, the exhaust pump 3 is installed on the described exhaust pipe 2, and the exhaust pipe 2 One end is an odor suction end 21, and the other end is an odor removal end 22. The odor intake end 21 is in sealing communication with the inner space of the housing, and the odor removal end 22 is used to output the odor to the sludge press. Workshop exterior.

[0037] During implementation, the odor removal end 22 is communicated with the delivery pipeline (not shown in the figure), and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com