A control method for preventing spindle bearing from burning out

A main shaft bearing and control program technology, applied in the field of control, can solve the problems of customer shutdown, burnt bearing, bearing burnout, etc., and achieve the effect of reducing replacement efficiency, reducing maintenance cost, and ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

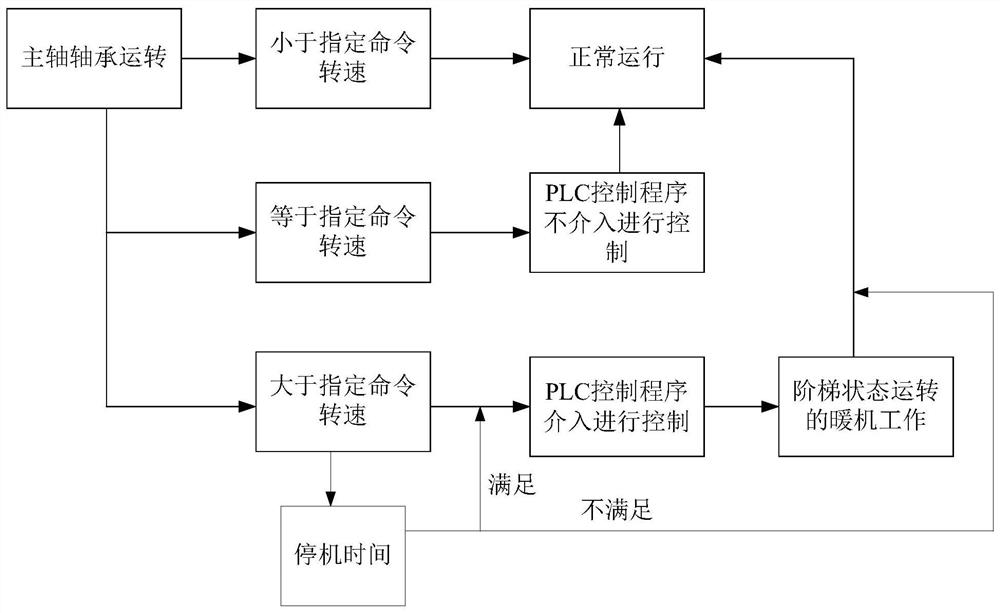

[0022] Such as figure 1 As shown, a control method for preventing spindle bearings from burning out. Before the spindle bearings of the machine tool perform high-speed work, the PLC control program is used to forcibly control the spindle bearings to perform warm-up work in a stepped state. By forcing the specified speed of the high-speed spindle bearing, it can reduce the damage to the spindle bearing and reduce the cost.

[0023] Among the present invention, PLC control program control mode comprises:

[0024] When the rotation speed of the spindle bearing is lower than the specified command speed, the downtime is satisfied or not, the PLC control program does not intervene in the control, and the spindle bearing of the machine tool works normally;

[0025] When the rotation speed of the spindle bearing is equal to the specified command speed, the downtime is satisfied or not, the PLC control program does not intervene to control, and the spindle bearing of the machine tool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com