A laser marking method for hard and brittle materials

A laser marking method and technology of hard and brittle materials, which is applied in the field of laser marking of hard and brittle materials, can solve the problems of material cracking and affecting marking clarity, and achieve the effect of avoiding cracking and improving clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

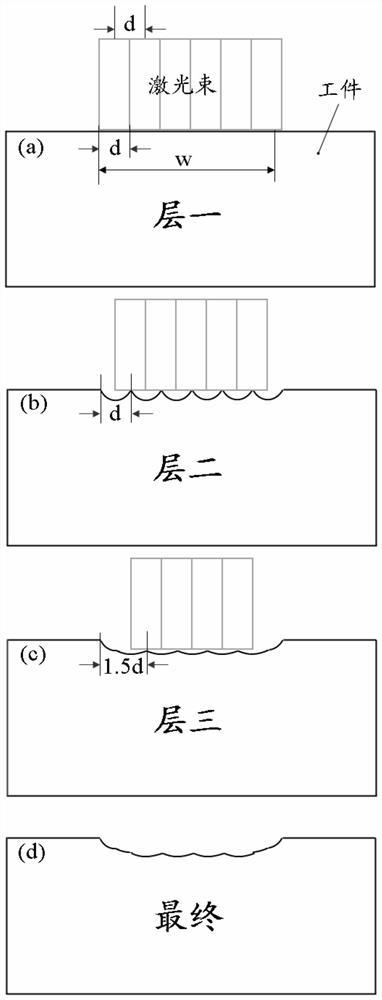

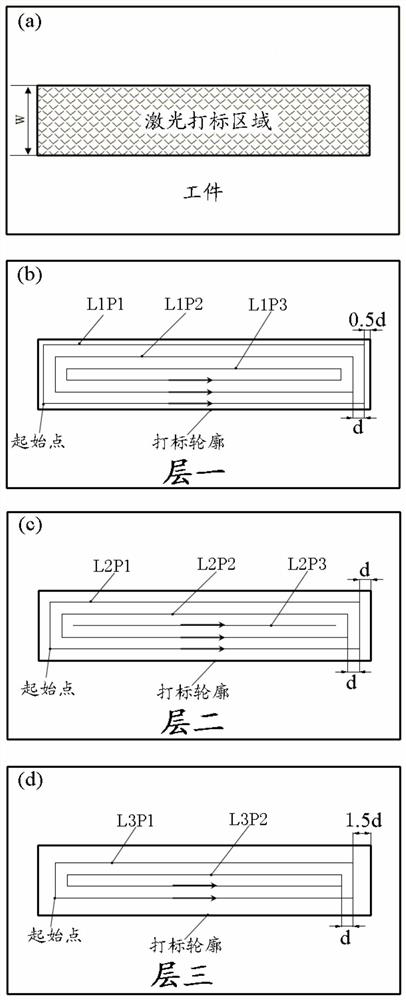

[0022] In this example, the laser is a pulsed fiber laser, the single pulse energy of the laser is 0.5mJ, the frequency is 20KHZ, the pulse width of the laser beam is 10ns, the wavelength is 1064nm, the laser spot diameter is 0.05mm, the scanning speed is 1m / s, and the hard and brittle material is silicon nitride. Laser marking on the surface of the workpiece such as figure 2 In the figure shown in (a), the width W of the figure is 0.28 mm, and the length is 5 mm. Specific steps are as follows:

[0023] Step 1: Input the required graphics or characters into the marking software, set the laser scanning path to scan along the boundary, and the scanning method is from outside to inside;

[0024] Step 2: the number of laser scanning paths n=W / 2d=2.8, rounding n to 3;

[0025] Step 3: With the laser parameters, from figure 2 (b) Start scanning from the starting point of the scanning path L1P1, and the distance between the centers of adjacent scanning paths is 0.05mm. After sc...

Embodiment 2

[0030] In this example, the laser is a pulsed fiber laser, the single pulse energy of the laser is 0.75mJ, the frequency is 35KHZ, the pulse width of the laser beam is 50ns, the wavelength is 1064nm, the diameter of the laser spot is 0.05mm, and the scanning speed is 1.25m / s. Hard and brittle materials for silicon nitride. Laser marking on the surface of the workpiece such as figure 2 In the figure shown in (a), the width W of the figure is 0.28 mm, and the length is 5 mm. Specific steps are as follows:

[0031] Step 1: Input the required graphics or characters into the marking software, set the laser scanning path to scan along the boundary, and the scanning method is from outside to inside;

[0032] Step 2: the number of laser scanning paths n=W / 2d=2.8, rounding n to 3;

[0033] Step 3: With the laser parameters, from figure 2 (b) Start scanning from the starting point of the scanning path L1P1, and the distance between the centers of adjacent scanning paths is 0.05mm....

Embodiment 3

[0038] In this example, the laser is a pulsed fiber laser, the single pulse energy of the laser is 1mJ, the frequency is 50KHZ, the pulse width of the laser beam is 10ns, the wavelength is 1064nm, the diameter of the laser spot is 0.05mm, the scanning speed is 1.5m / s, and the hard and brittle material is silicon nitride. Laser marking on the surface of the workpiece such as figure 2 In the figure shown in (a), the width W of the figure is 0.28 mm, and the length is 5 mm. Specific steps are as follows:

[0039] Step 1: Input the required graphics or characters into the marking software, set the laser scanning path to scan along the boundary, and the scanning method is from outside to inside;

[0040] Step 2: the number of laser scanning paths n=W / 2d=2.8, rounding n to 3;

[0041] Step 3: With the laser parameters, from figure 2 (b) Start scanning from the starting point of the scanning path L1P1, and the distance between the centers of adjacent scanning paths is 0.05mm. Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com