Gang saw welding machine

A technology of welding machine and frame, applied in the field of welding equipment and gang saw welding machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

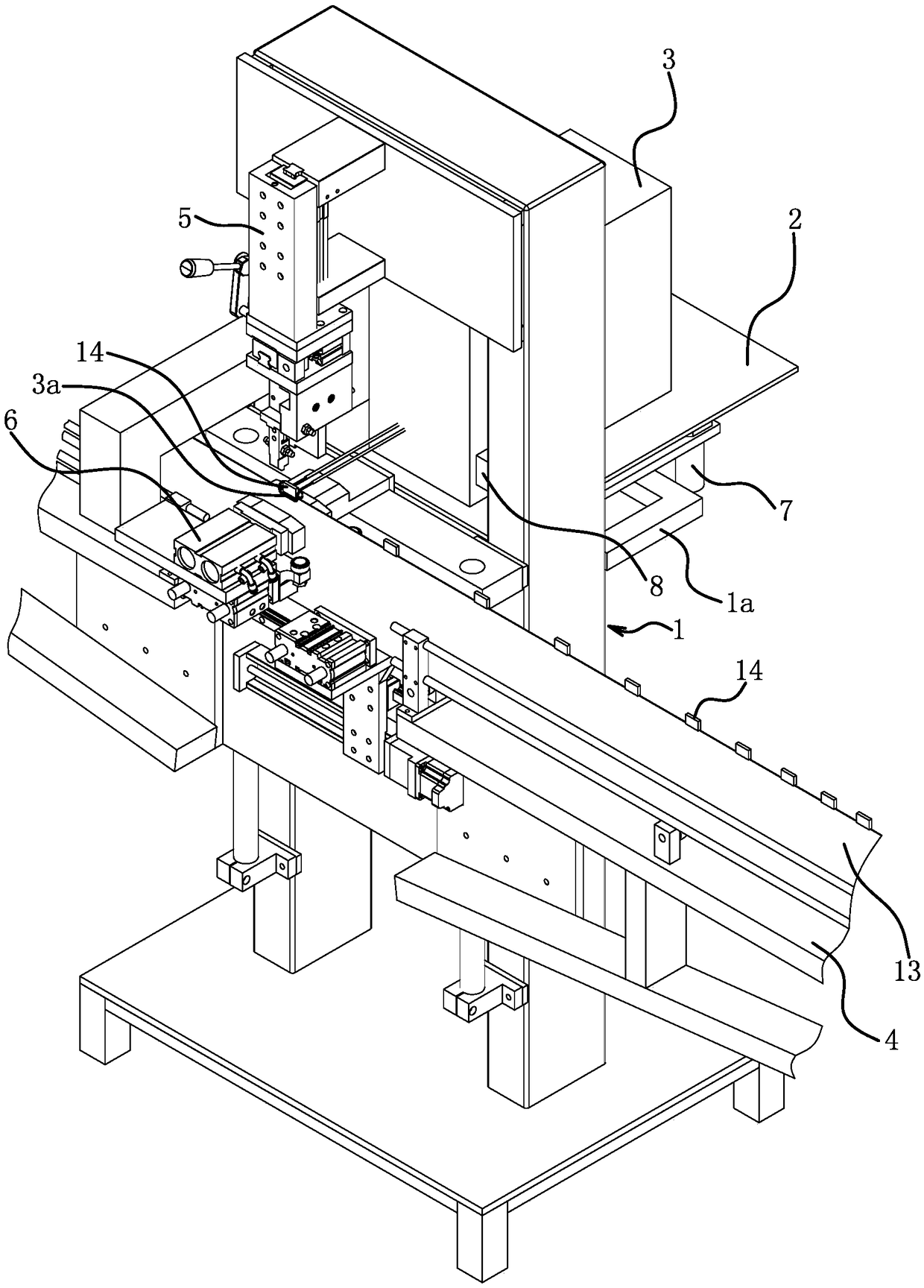

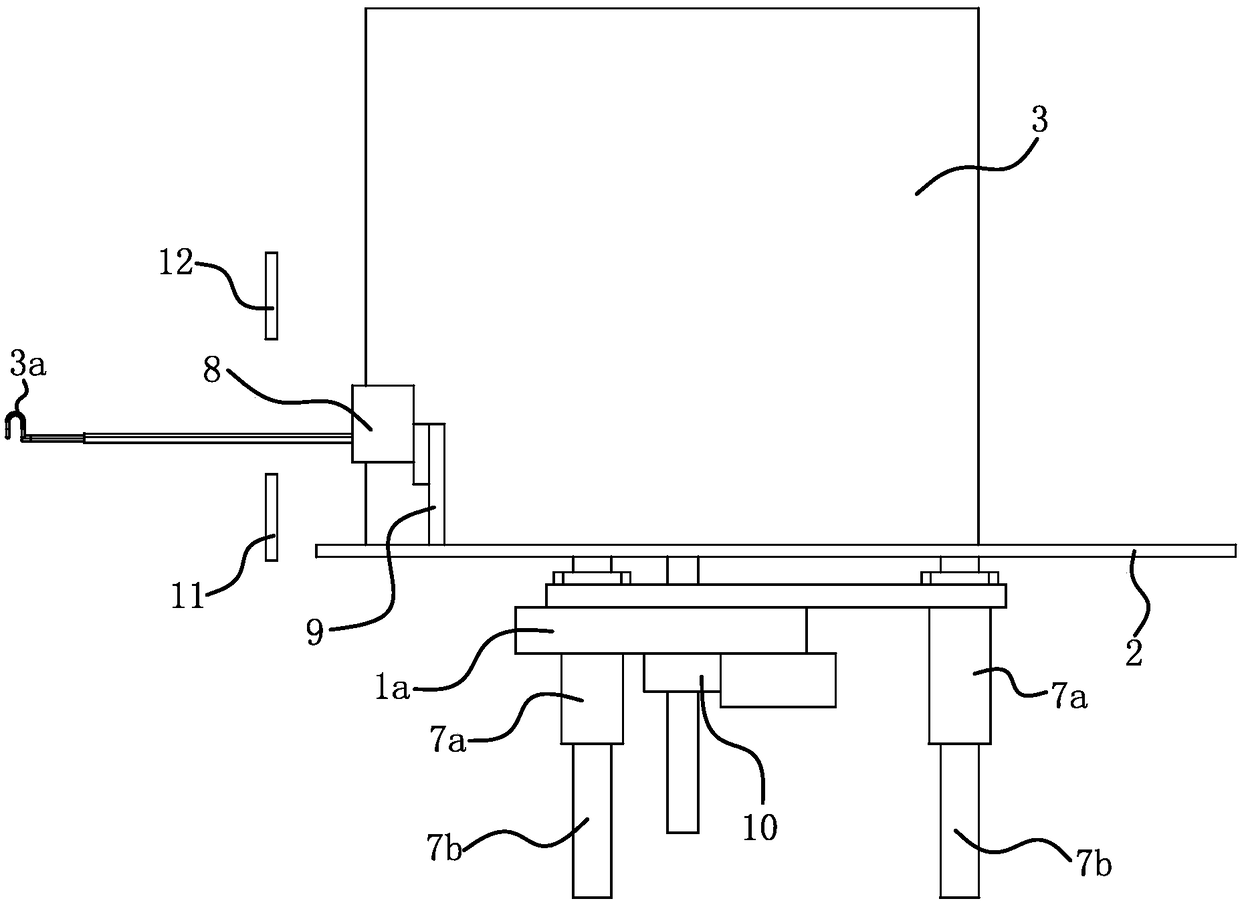

[0012] A gang saw welding machine includes a frame 1, a platform 2 for placing heating equipment, a sensor for detecting the position of the upper edge of a saw board 13, and a control circuit.

[0013] The gang saw welding machine also includes components such as a saw board positioning device 4 , a cutter head clamping device 5 and a saw board clamping device 6 installed on the frame 1 . The rear side of the frame 1 has a suspension frame 1a, and the platform 2 is located above the suspension frame 1a, and the platform 2 and the suspension frame 1a are connected by a guide structure 7 that enables the platform 2 to move vertically. Specifically, a plurality of guide sleeves 7a are fixed on the cantilever frame 1a, and a guide rod 7b is pierced in each guide sleeve 7a, and the upper end of the guide rod 7b is fixedly connected with the platform 2 . This structure significantly improves the lifting stability of the platform 2, and significantly reduces the possibility of displ...

Embodiment 2

[0022] The structure and principle of this embodiment are basically the same as that of Embodiment 1. The basic similarities will not be described in detail, and only the differences will be described. The difference is that the sensor is a distance measuring sensor, and the distance measuring sensor is located in the saw board positioning device. 4 directly above. The saw board 13 is installed in the saw board positioning device 4 and the upper edge surface of the upper saw board 13 is facing the distance sensor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com