Automatic waxing device

An automatic and wax block technology, which is applied in the direction of grinding automatic control devices, grinding machines, grinding machine parts, etc., can solve problems that affect production efficiency, easily produce waste products, and uneven waxing, so as to improve equipment safety, The effect of improving product quality and removing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

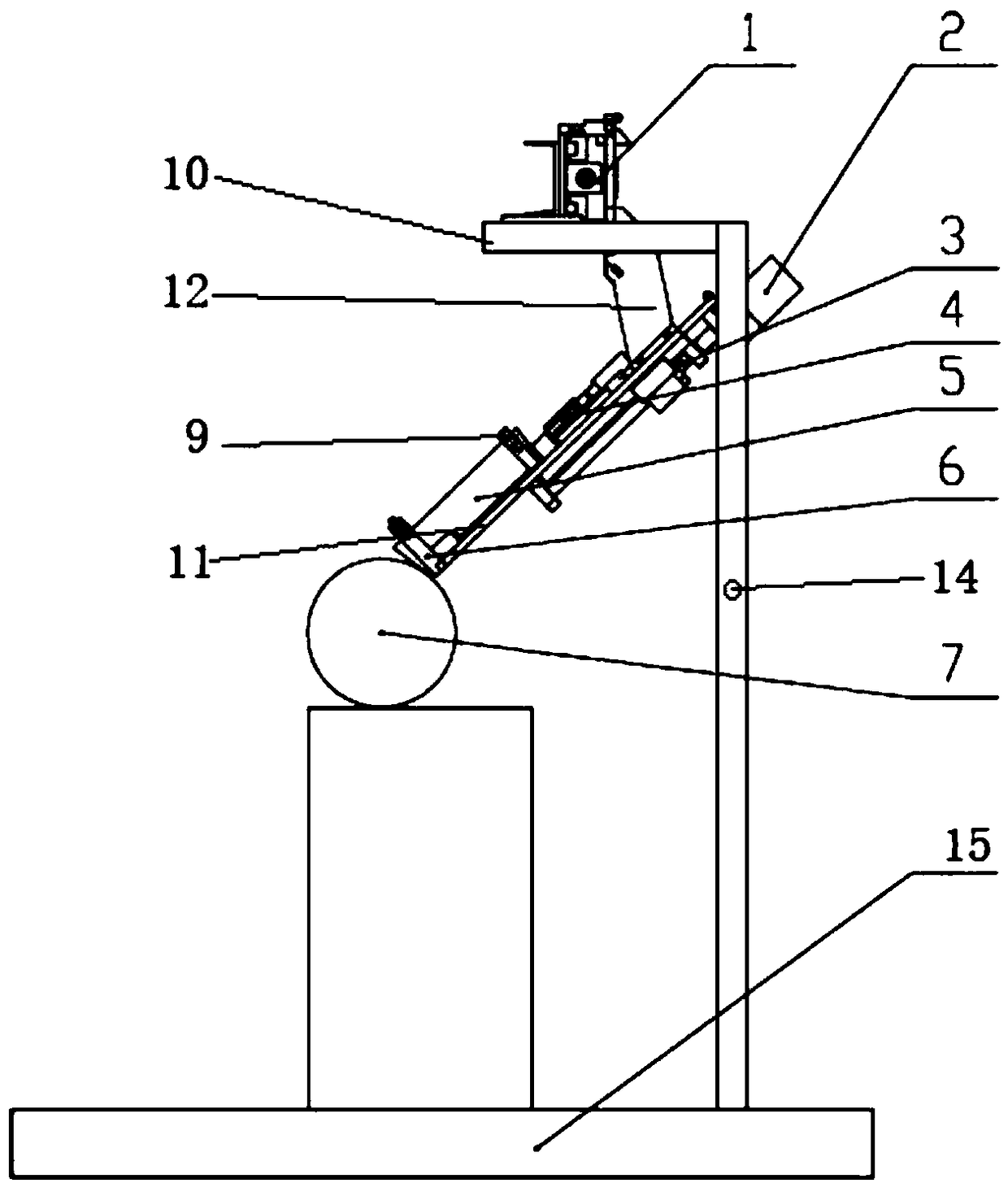

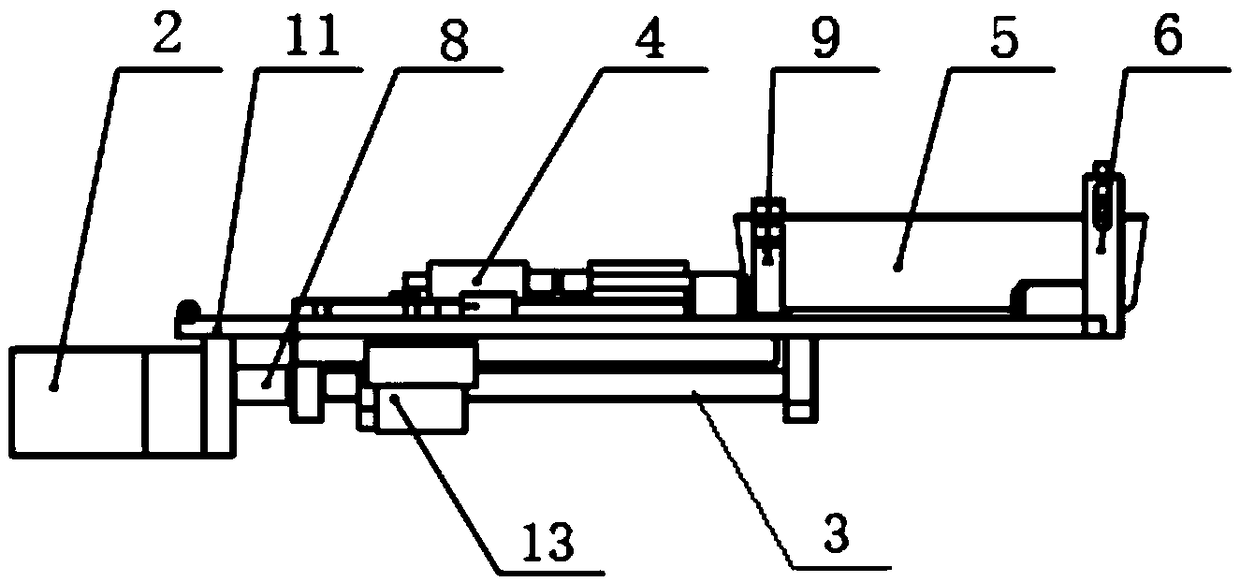

[0025] The invention provides an automatic waxing device, specifically as figure 1 and figure 2 As shown, it includes a horizontal driving module 1, a wax block feeding module and a supporting module;

[0026] The horizontal driving module 1 is arranged on the support module, and the horizontal driving module 1 is connected with the wax block feeding module to drive the wax block feeding module to move in the horizontal direction.

[0027] Specifically, the wax block feeding module includes a ball screw module, a pressure sensor 4, an adjustment head 9, a replacement head 6 and a support plate 11, the support plate 11 is inclined, the upper end of the support plate 11 is connected with the connecting plate 12, and the pressure sensor 4 is set At the upper end of the support plate 11 surface, the replacement head 6 and the adjustment head 9 are successively arranged on the lower end of the support plate 11 surface. The wax block 5 is housed in the replacement head 6 and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com