Low-cost paint-free moisture-proof formaldehyde-free solid wood composite furniture board and a preparation process thereof

A solid wood composite and preparation process technology, applied in the direction of wood layer products, wood processing appliances, wood veneer bonding, etc., can solve the problems of high quality, low cost and high cost, achieve high board performance and save materials The effect of cost, high quality advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the content of the present invention easier to understand, the technical solutions of the present invention will be further described below in conjunction with specific embodiments, but the present invention is not limited to this.

[0051] The solid wood composite furniture board with a thickness specification of 18mm of the present invention belongs to a thick-core multilayer plywood substrate paint-free, moisture-proof, and aldehyde-free solid wood composite furniture board:

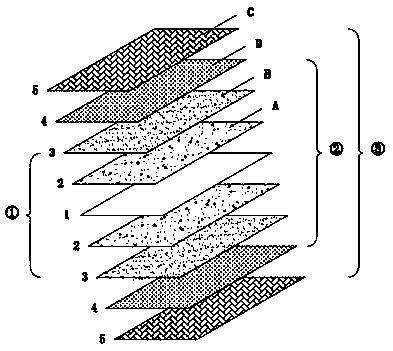

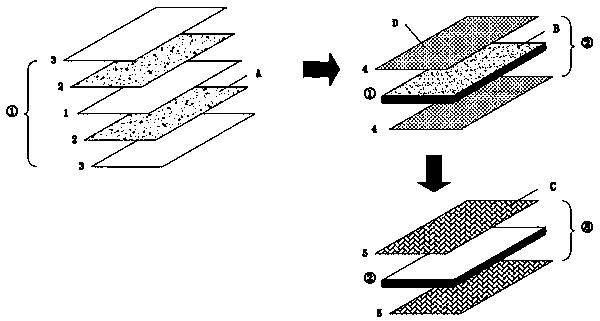

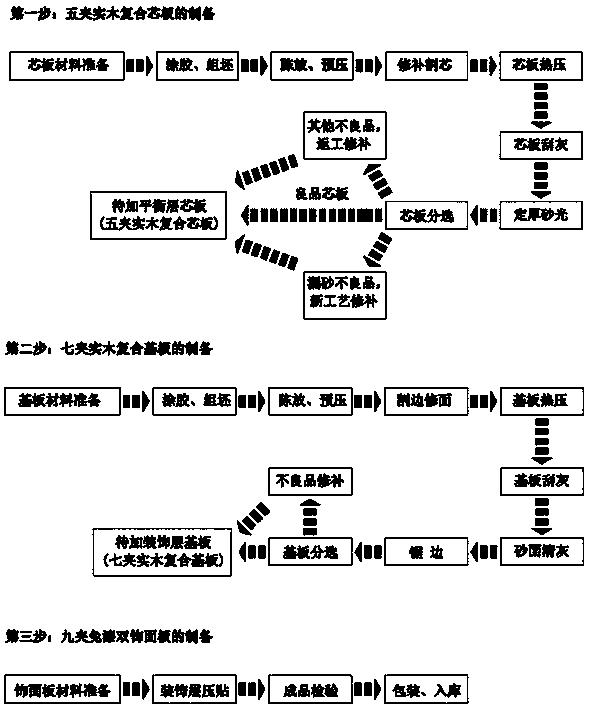

[0052] (1) Design of slab structure

[0053] The combined structure of each layer of the furniture slab is composed of nine layers of materials, such as figure 1 As shown, the various layers of materials that make up the slab are arranged from the center layer to both sides, from the inside to the outside, in order: the center short and medium layer 1, the long and medium layer 2 two layers, and the outer short and medium layer 3 two layers , Two-layer aldehyde balance layer 4, two-la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com