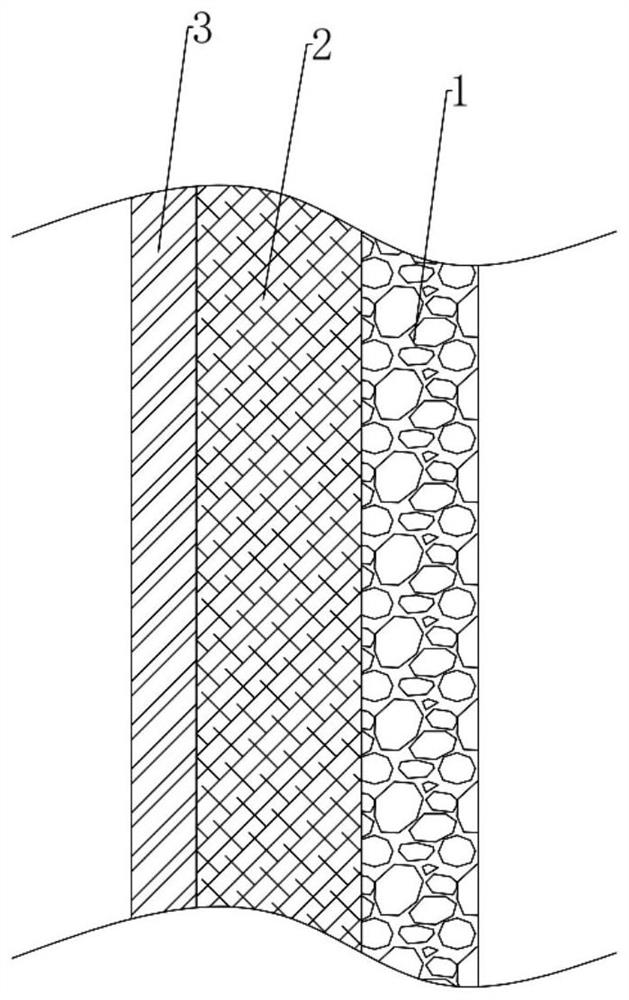

A wave-absorbing composite board and its application

A composite board and composite material technology, applied in the field of electromagnetic wave-absorbing structures, can solve the problems of free space impedance matching imbalance, low electromagnetic wave absorption rate, single structural design, etc., and achieve good frost resistance and corrosion resistance, and compressive strength High, the effect of reducing resource waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation method of the electromagnetic wave transmissive composite material comprises the following steps:

[0051] (1) prepare alkali activator: water, water glass and sodium hydroxide are mixed, stir, then leave standstill 24h, obtain alkali activator; By mass ratio, water: water glass: sodium hydroxide=(45~55 ):1:2;

[0052] (2) Preparation of the first alkali-activated slag cementitious material: add fly ash and slag to a slurry mixer, stir evenly to obtain a mixed ash body, then add an alkali activator, and stir evenly to obtain the first alkali-activated slag Cementitious material; by mass ratio, fly ash: slag = (7:5) ~ (10:3), mixed ash body: alkali activator = 1: (0.4 ~ 0.5);

[0053] (3) Sodium bicarbonate is added in the epoxy resin glue, stir evenly, obtain mixture A; According to mass volume ratio, sodium bicarbonate: epoxy resin glue=2~3g:20~30mL;

[0054] (4) Wash the expanded polystyrene particles with deionized water for 2-3 times, and then dry th...

Embodiment 1

[0068] Embodiment 1 provides an electromagnetic wave transmission composite material, the preparation method of which includes the following steps:

[0069] (1) prepare alkali activator: mix water, water glass and sodium hydroxide, stir 8~10min, then leave standstill 24h, obtain alkali activator; By mass ratio, water: water glass: sodium hydroxide=50: 1:2;

[0070] (2) Preparation of the first alkali-activated slag cementitious material: add fly ash and slag to a slurry mixer, stir for 120-150 seconds to obtain a mixed ash body, then add an alkali activator, and stir for 4-5 minutes to obtain the first A kind of alkali-activated slag cementitious material; By mass ratio, fly ash: slag=7:3, mixed ash body: alkali activator=1:0.4;

[0071] (3) Sodium bicarbonate is added in the epoxy resin glue, stirs 3~5min, obtains mixture A; According to mass volume ratio, sodium bicarbonate:epoxy resin glue=1g:10mL;

[0072] (4) Wash the expanded polystyrene particles with deionized water ...

Embodiment 2

[0079] Embodiment 2 provides an electromagnetic wave transmission composite material, the preparation method of which includes the following steps:

[0080] (1) prepare alkali activator: mix water, water glass and sodium hydroxide, stir 8~10min, then leave standstill 24h, obtain alkali activator; By mass ratio, water: water glass: sodium hydroxide=45: 1:2;

[0081] (2) Preparation of the first alkali-activated slag cementitious material: add fly ash and slag to a slurry mixer, stir for 120-150 seconds to obtain a mixed ash body, then add an alkali activator, and stir for 4-5 minutes to obtain the first A kind of alkali-activated slag cementitious material; By mass ratio, fly ash: slag=7:5, mixed ash body: alkali activator=1:0.45;

[0082] (3) Sodium bicarbonate is added in the epoxy resin glue, stirs 3~5min, obtains mixture A; According to mass volume ratio, sodium bicarbonate:epoxy resin glue=2g:30mL;

[0083] (4) Wash the expanded polystyrene particles with deionized water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com