Water platform

A water platform and platform technology, which is applied to floating buildings and other directions, can solve the problems of low wind and wave resistance and safety performance of the platform, and achieve the effects of good wind and wave resistance and safety performance, simple structure and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

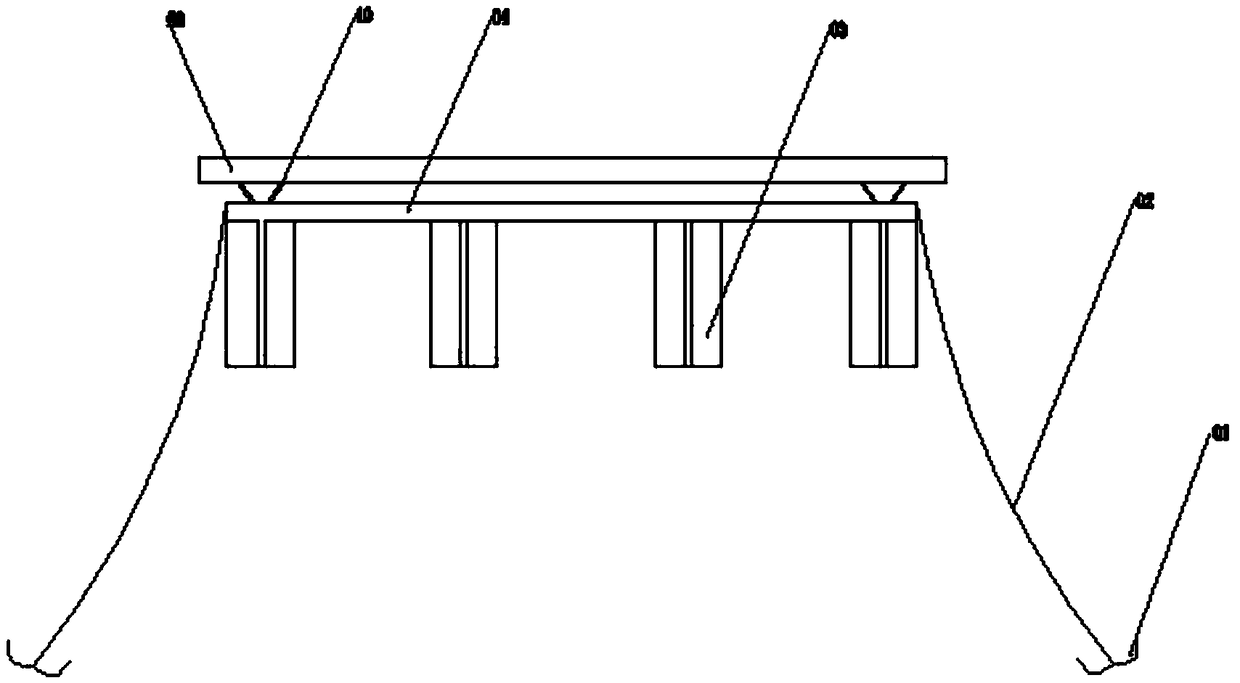

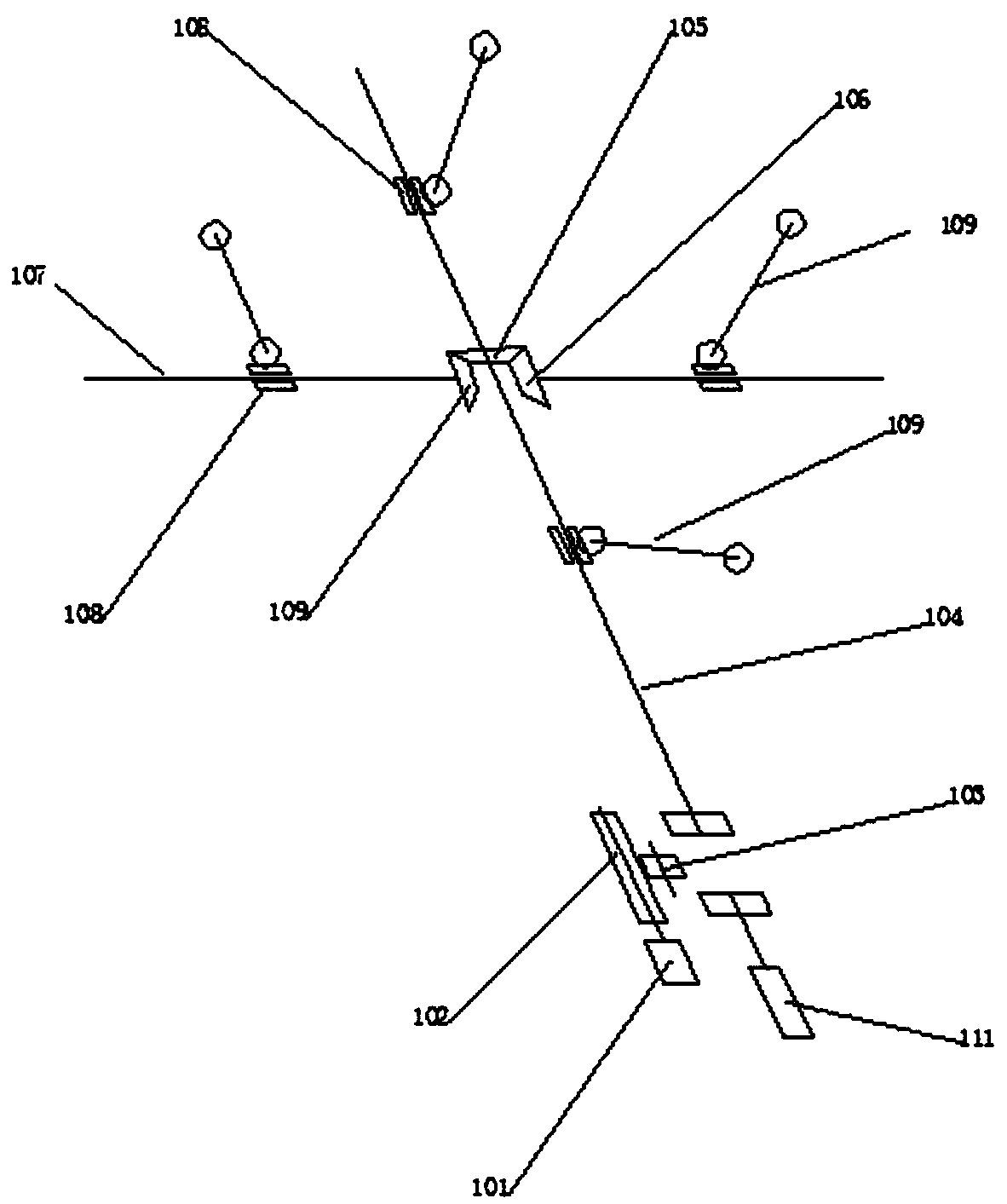

[0018] Embodiment one: combined with attached figure 1 , 2 A water platform, including 12 fiberglass buoys (03) with a diameter of 2 meters and a height of 3 meters, the buoys (03) are arranged in a 3x4 rectangular array, the central cylinder of the buoys (03) is inserted into a steel pipe, and the steel pipe is rotatably connected to the connecting body (04) , each of the four corners of the connecting body (04) is provided with an adjusting device (10), each adjusting device (10) drives a main screw (104) for the motor (101) through the clutch (103), the main screw The two sides of (104) have opposite helical threads. A main bevel gear (105) is arranged in the middle of the main screw (104). The two sides of the main bevel gear (105) respectively drive a driven bevel gear (106). (106) each drives a driven lead screw (107), and each of the four sections of the lead screw is provided with a slide block (108) matching the thread, and each slide block (108) top is hinged with a...

Embodiment 2

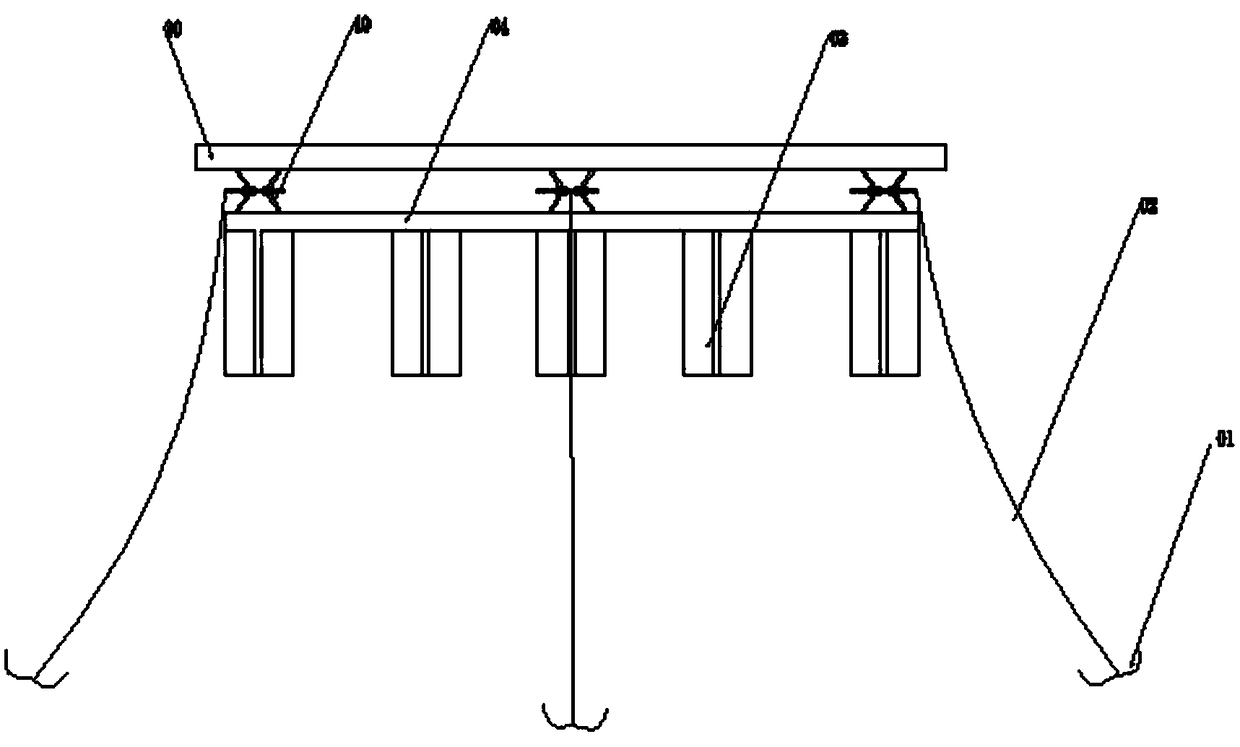

[0020] Embodiment two, combined with figure 2 , 3 , a water platform, including 15 elliptical fiberglass buoys (031) with a short diameter of 2.2 meters and a long diameter of 3.6 meters. (04) is fixedly connected, and the connecting body (04) is provided with six adjustment devices (10), and the difference between each adjustment device (10) and embodiment 1 is: the bottom of each slide block (108) is hinged with The lower support rod (110), the lower end of the lower support rod (110) is hinged with the connecting body (04), so that the upper and lower support rods (110) form a symmetrical structure. The upper support rods (109) are arranged in an inverted splayed shape, and the lower support rods (110) are arranged in a straight splayed figure. When the upper and lower support rods are in a line, the distance between the platform main body (20) and the connecting body (04) is the largest. Such a structure avoids the sliding connection of the slider (108) on the connectin...

Embodiment 3

[0021] Embodiment three: combined with attached Figure 5 , a water platform, including 24 ship-shaped fiberglass buoys (032) with a maximum width of 2.2 meters and a length of 3.6 meters. The buoys (032) are arranged in a 4x7 rectangular array. ) is fixedly connected, and the connecting body (04) is provided with eight adjusting devices (10). The difference between each adjusting device (10) and Embodiment 2 is that four winches (111) on one side of the water platform drive the anchor (01), four capstans (111) on the other side of the anchor chain (01) connect the positioning piles (112) by the anchor chain (01) respectively. Other structures and working principles are the same as those in Embodiment 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com