An offshore platform

An offshore platform and platform technology, which is applied to floating buildings and other directions, can solve the problems of low wind and wave resistance and safety performance of the platform, and achieve the effects of good wind and wave resistance and safety performance, simple structure and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

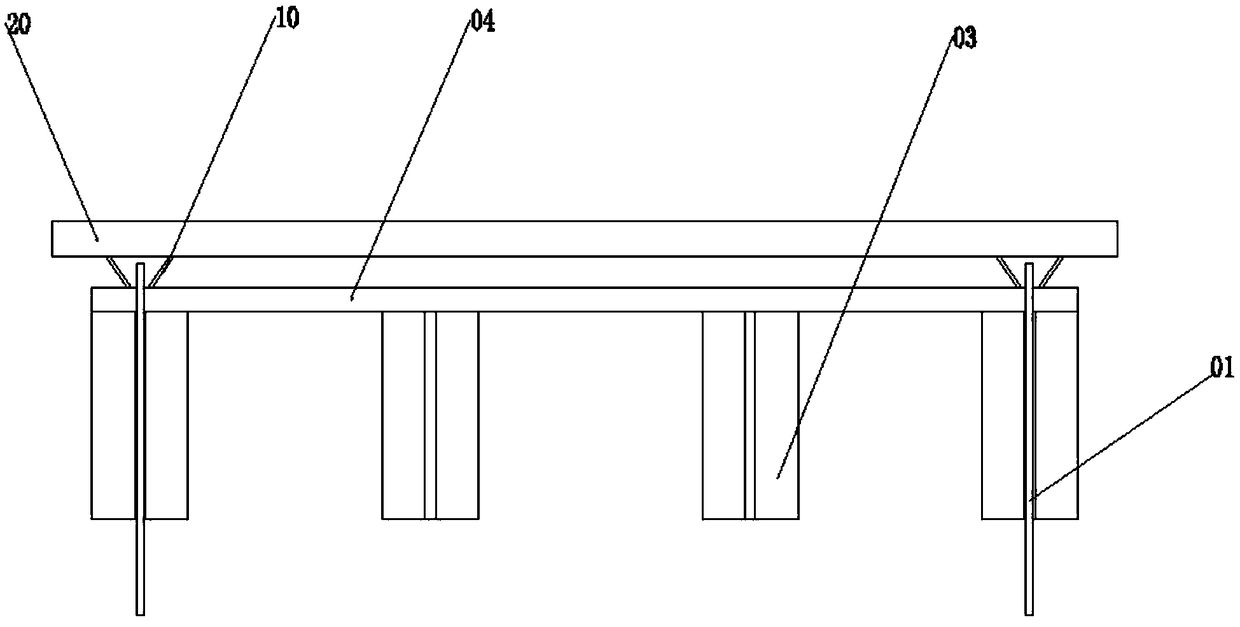

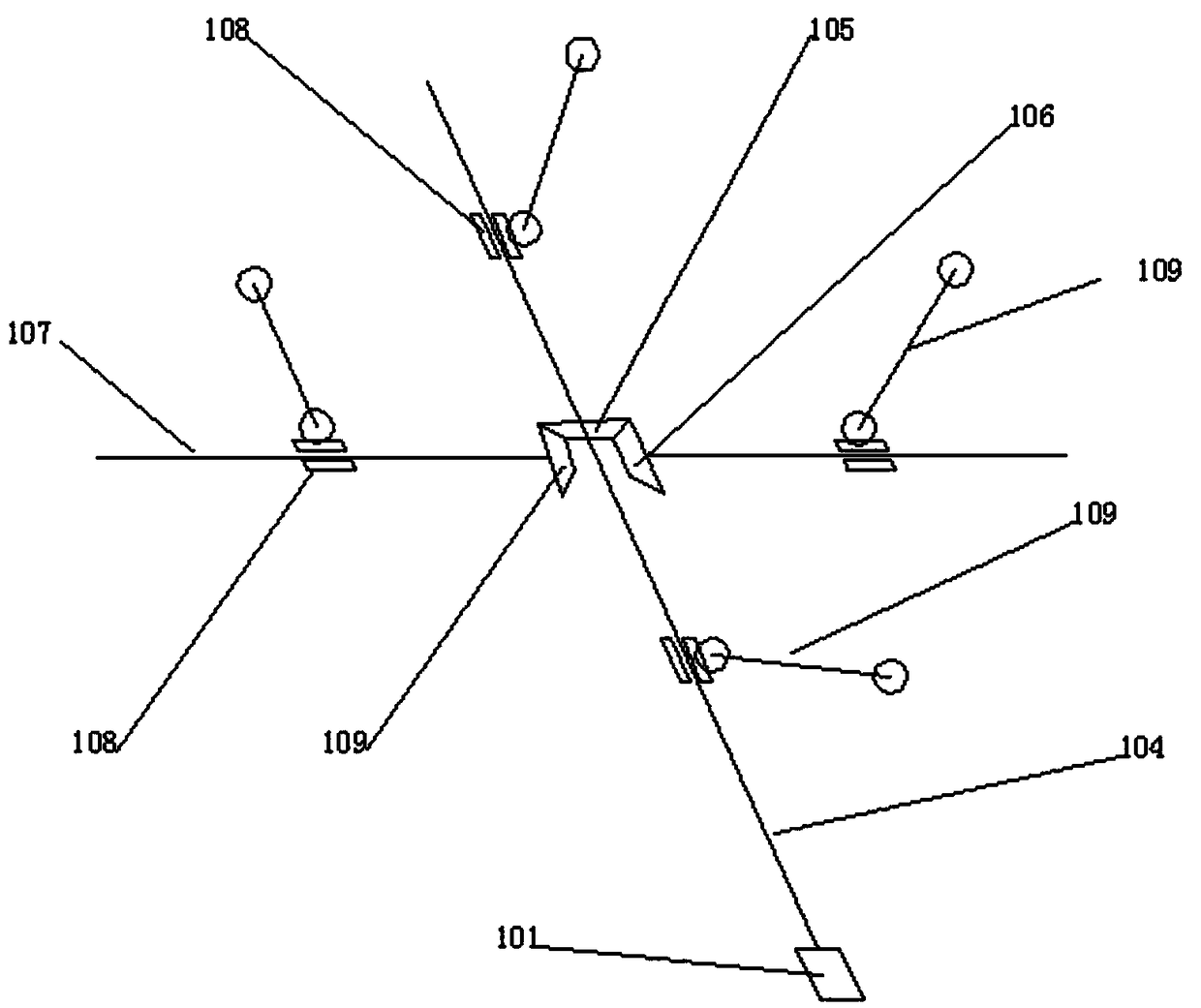

[0020] Embodiment one: combined with attached figure 1 , 2 An offshore platform, comprising 12 fiberglass buoys (03) with a diameter of 2 meters and a height of 3 meters, the buoys (03) are arranged in a 3x4 rectangle, the central cylinder of the buoys (03) is inserted into a steel pipe, and the steel pipe is fixedly connected to the connecting body (04), Steel pipe piles (01) are respectively inserted into the steel pipes of the buoys (03) on the four corners of the platform, and the steel pipe piles (01) are inserted into the seabed; an adjustment device (10 ), each adjusting device (10) drives a main screw (104) for the motor (101), the two sides of the main screw (104) have threads in opposite directions, and the middle part of the main screw (104) is provided with a main bevel gear (105), the main bevel gear (105) both sides drives a driven bevel gear (106) respectively, and the driven bevel gear (106) respectively drives a driven lead screw (107), and each of the four s...

Embodiment 2

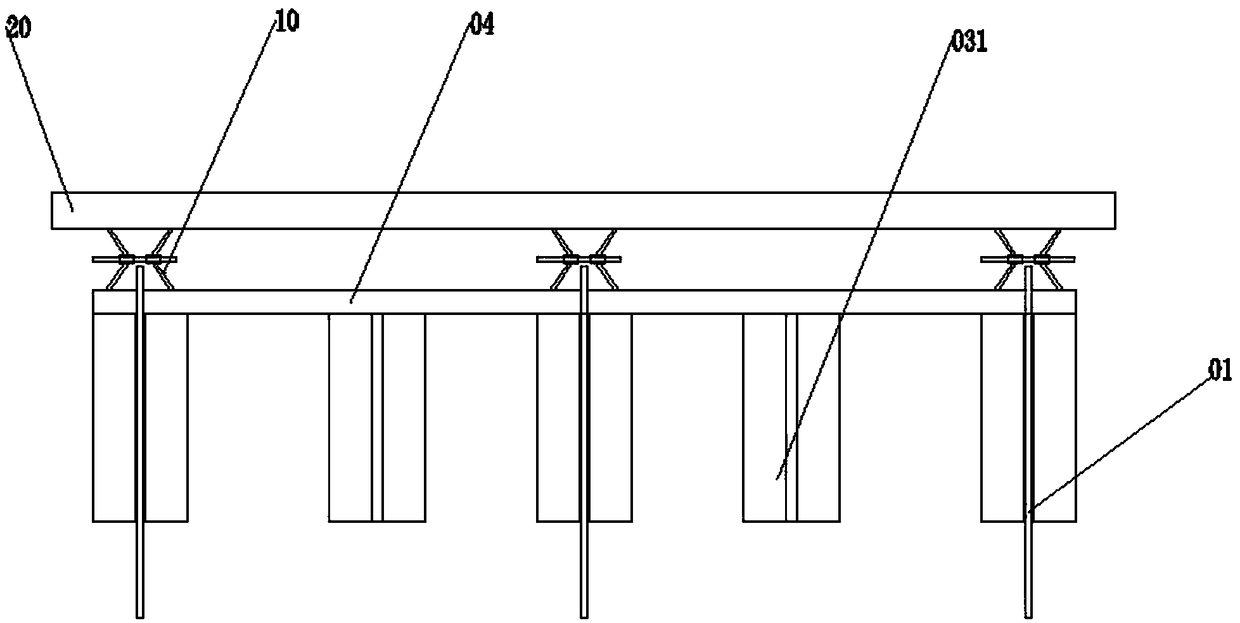

[0022] Embodiment two, combined with figure 2 , 3 , an offshore platform, comprising 15 elliptical fiberglass buoys (031) with a short diameter of 2.2 meters and a long diameter of 3.6 meters, the buoys (031) are arranged in a 3x5 rectangle, the central cylinder of the buoys (031) is inserted into a steel pipe, and the steel pipe and the connecting body ( 04) Fixed connection, the steel pipe is connected with the buoy (031) in rotation, and the steel pipe piles (01) are respectively inserted into the six steel pipes on the long sides of the platform; the connecting body (04) is provided with six adjustment devices (10) , the difference between each adjustment device (10) and Embodiment 1 is: the lower support rod (110) is respectively hinged at the bottom of each slide block (108), and the lower end of the lower support rod (110) is connected to the connecting body (04) Hinged so that the upper and lower support rods (110) form a symmetrical structure. Each pair of upper su...

Embodiment 3

[0023] Embodiment three: combined with attached Figure 5 , an offshore platform, including 24 ship-shaped fiberglass buoys (032) with a maximum width of 2.2 meters and a length of 3.6 meters. The buoys (032) are arranged in a 4x7 rectangle. The central cylinder of the buoys (032) is inserted into a steel pipe, and the steel pipe and the connecting body (04) Fixed connection, the steel pipe is connected with the buoy (031) in rotation; eight adjustment devices (10) are arranged on the connection body (04), and each adjustment device (10) is respectively inserted into the eight steel pipes on the long sides of the platform Steel pipe piles (01), four corner steel pipe piles on the platform main body (20) are respectively provided with a steel pipe pile holding device (201).

[0024]On this offshore platform, the steel pipe piles can be driven in separately using a pile driver. In the case of soft ground, the steel pipe piles (01) can be inserted into the steel pipes of the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com