Automatic bundling equipment for junction box

A junction box, automatic technology, applied in the direction of bundling materials, packaging, etc., can solve the problems of junction box tying failure, easy loosening, affecting construction period and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

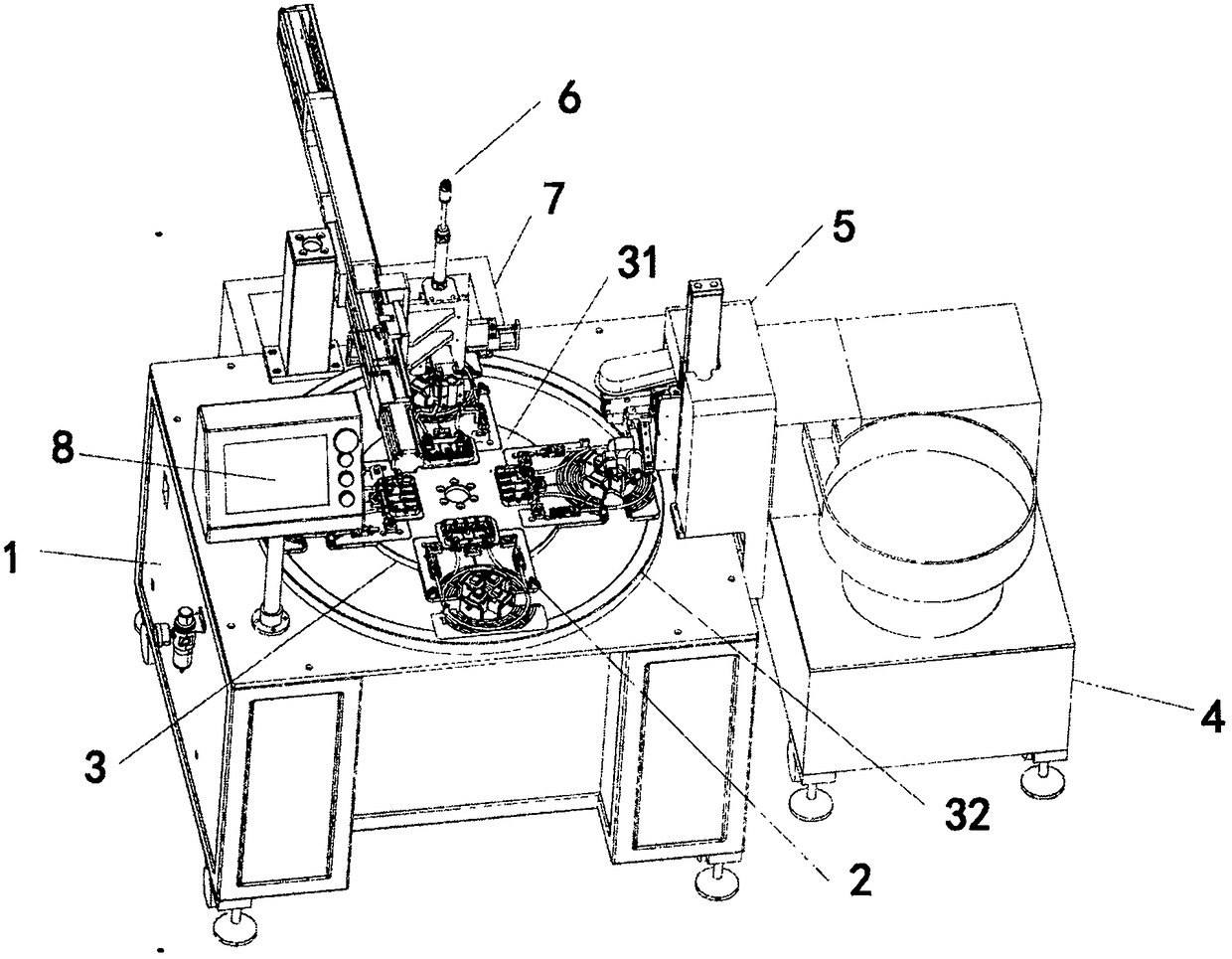

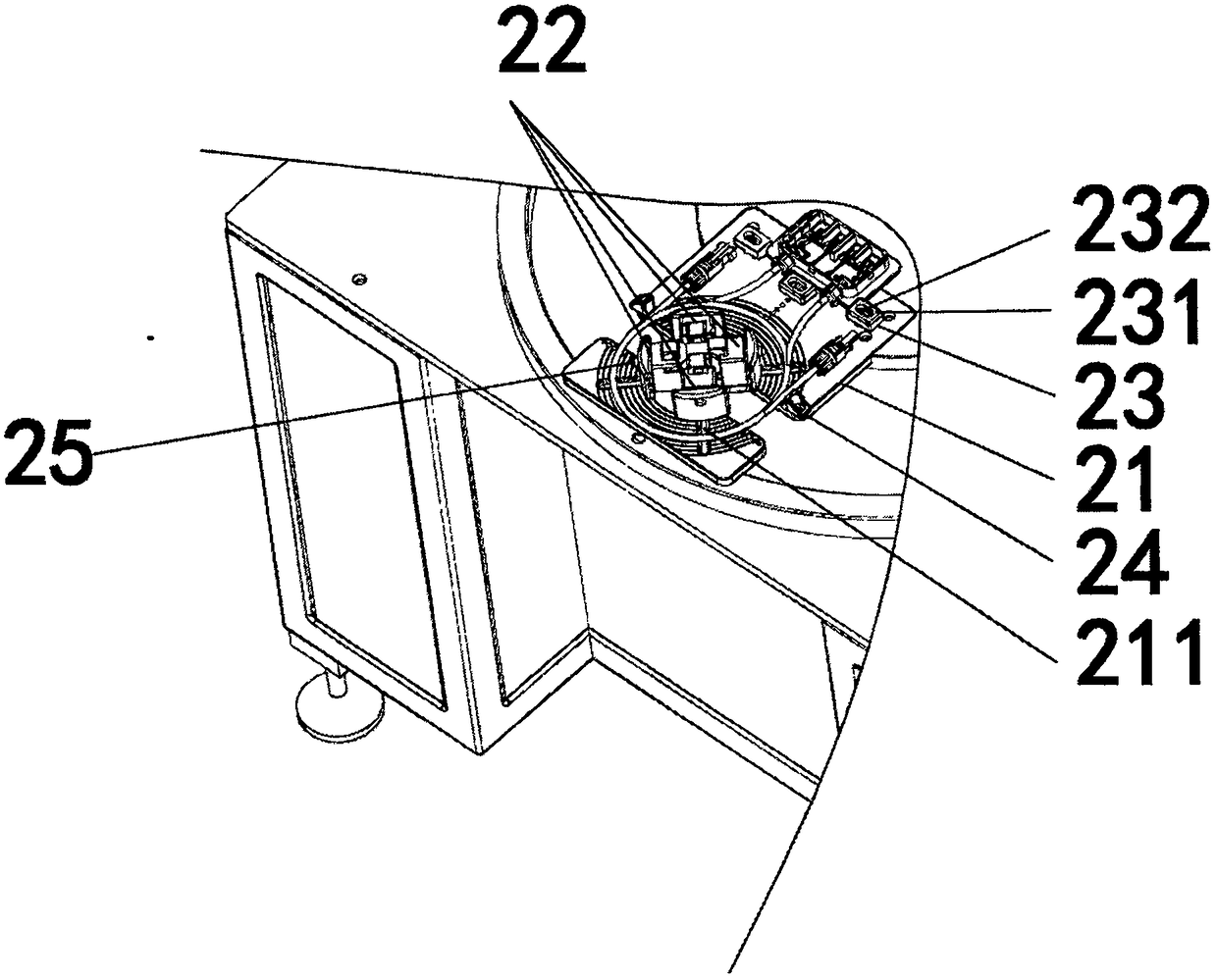

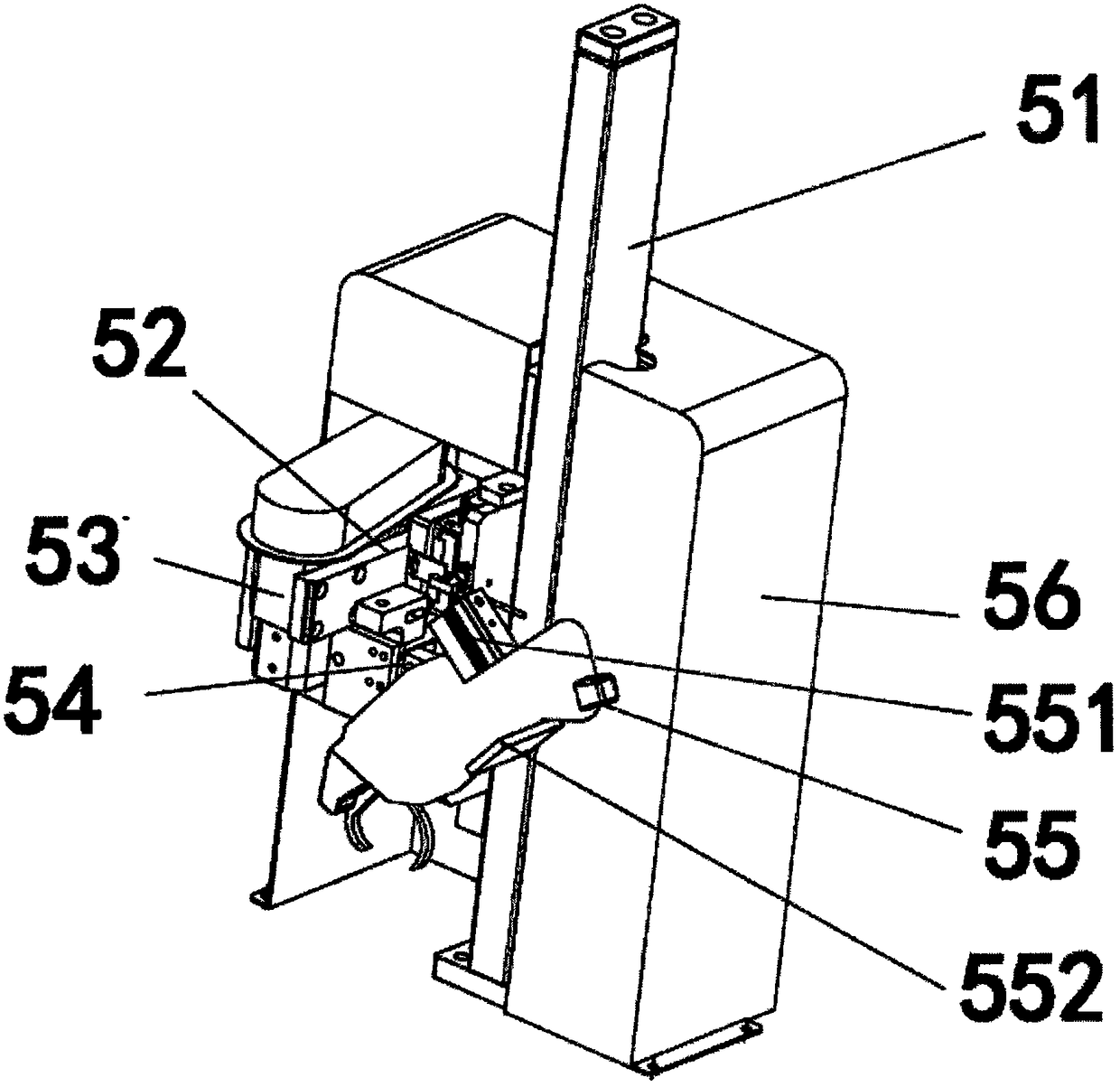

[0023] Such as Figure 1-Figure 6 As shown, a junction box automatic binding equipment described in this embodiment includes a workbench 1 and a vibrating feeder 4. A plurality of winding tools 2 for winding and positioning the junction box are installed on the workbench 1, and the winding The positioned junction box is sent to the automatic transmission mechanism 3 at the automatic wire binding mechanism 5, the automatic wire binding mechanism for automatically bilaterally binding the junction box delivered by the automatic transmission mechanism 3, and the junction box that has been tied The automatic feeding mechanism 6 taken away from the transmission mechanism 3, and the servo console 8 for automatic control of the automatic thread binding mechanism 5, the vibration feeding machine 4, and the automatic feeding mechanism 6; the distribution of the vibration feeding machine 4 The mechanism is connected to the feeding port of the automatic wire-tying mechanism 5 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com