Swing system and swing control method for aerial work platform

An aerial work platform and controller technology, which is applied to fluid pressure actuating devices, servo motors, lifting devices, etc., can solve problems such as high cost of proportional valves, difficulty in accurately controlling the moving position of the gondola, and great influence of speed control. , to achieve the effect of improving energy saving, controllability and fretting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with specific drawings and embodiments.

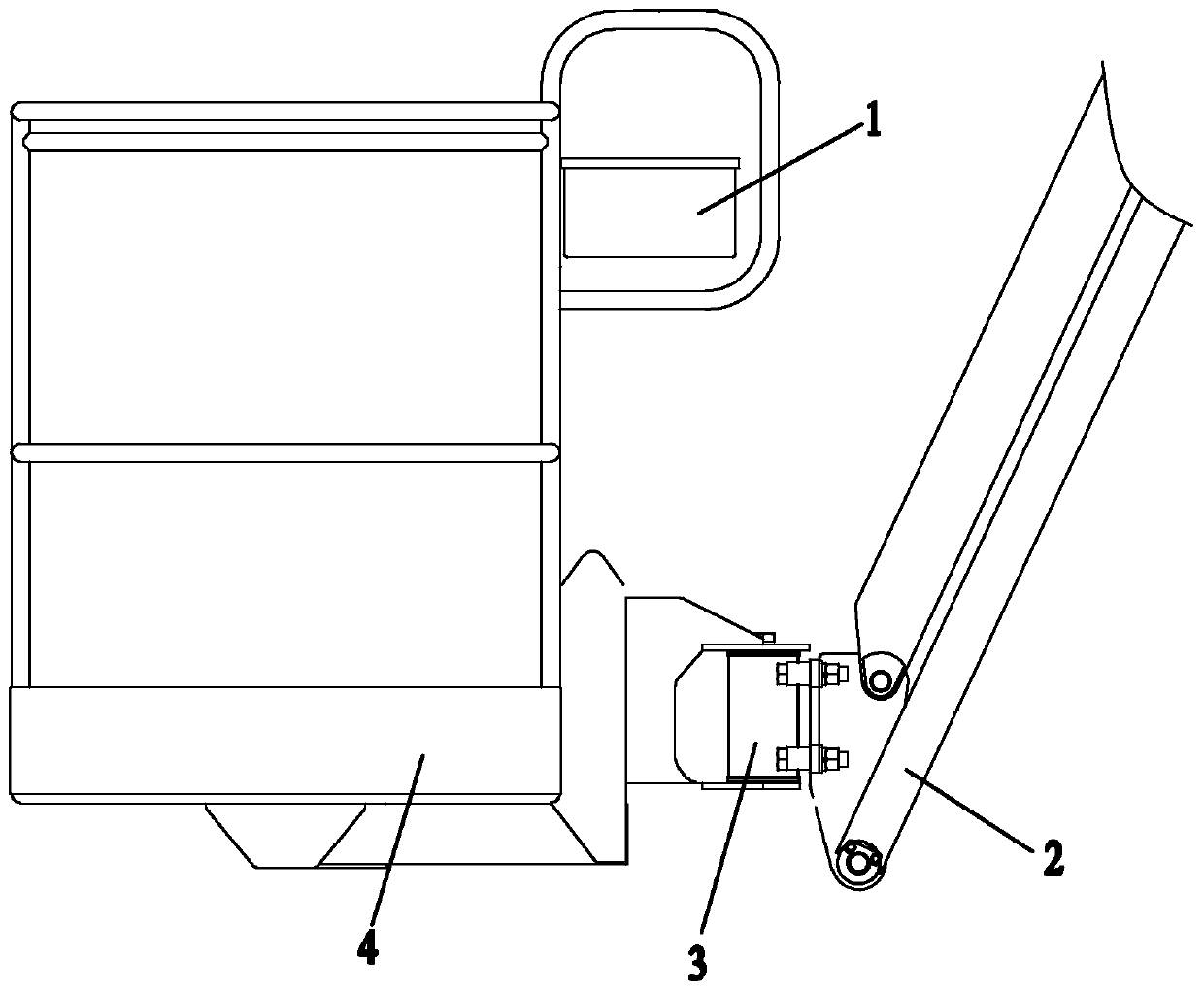

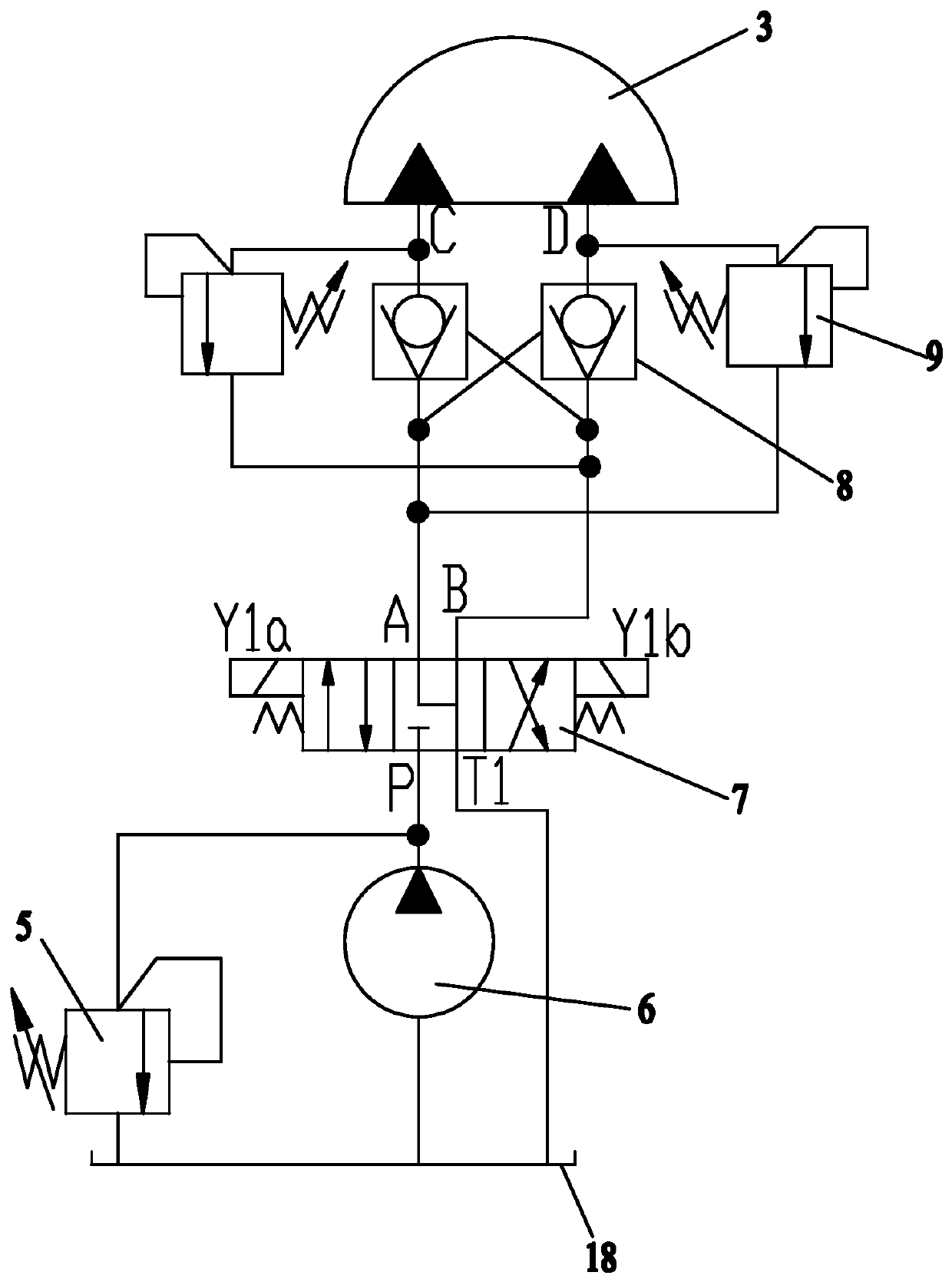

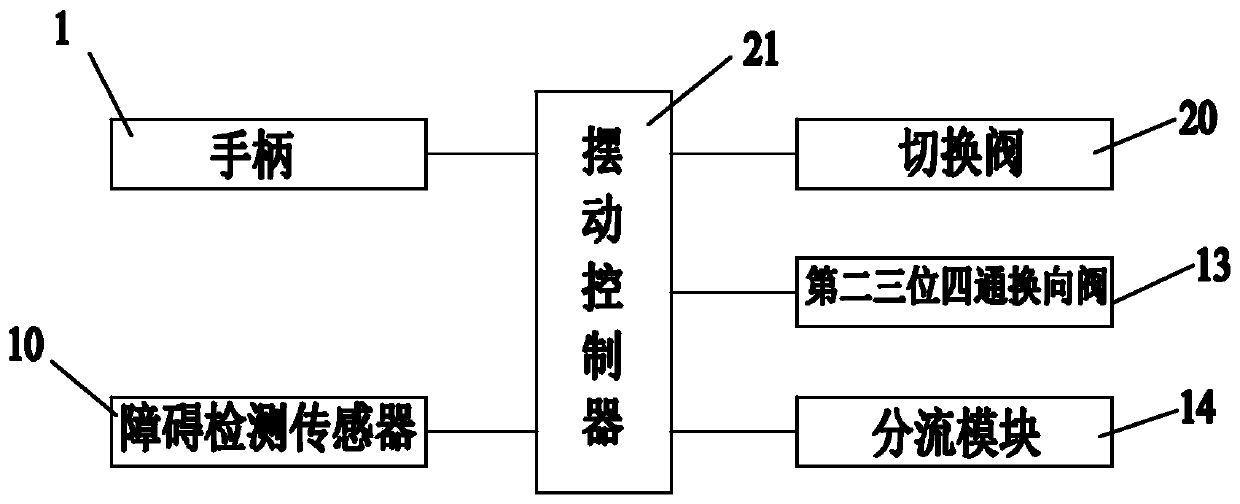

[0037] Such as image 3 and Figure 4 As shown: in order to effectively control the swing speed of the hanging basket 4 according to the angle of the handle, the present invention includes a hanging basket 4, a swing cylinder 3 for driving the hanging basket 4 to swing, and a handle for manipulating the swinging state of the hanging basket 4 1; It also includes a hydraulic swing control circuit for driving and controlling the work of the swing cylinder 3 and a swing controller 21 electrically connected to the handle 1;

[0038] The hydraulic swing control circuit includes a constant pressure variable pump 11, a second three-position four-way reversing valve 13 for controlling the reversing of the swing cylinder 3, and a regulator for stabilizing the flow through the second three-position four-way reversing valve 13. The speed valve 12 and the balance valve va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com