Reaction equipment for degrading ammonia-nitrogen

A reaction equipment and ammonia nitrogen technology, applied in the field of environmental engineering, can solve the problems of unsuitable combination of multiple water treatment methods and single function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

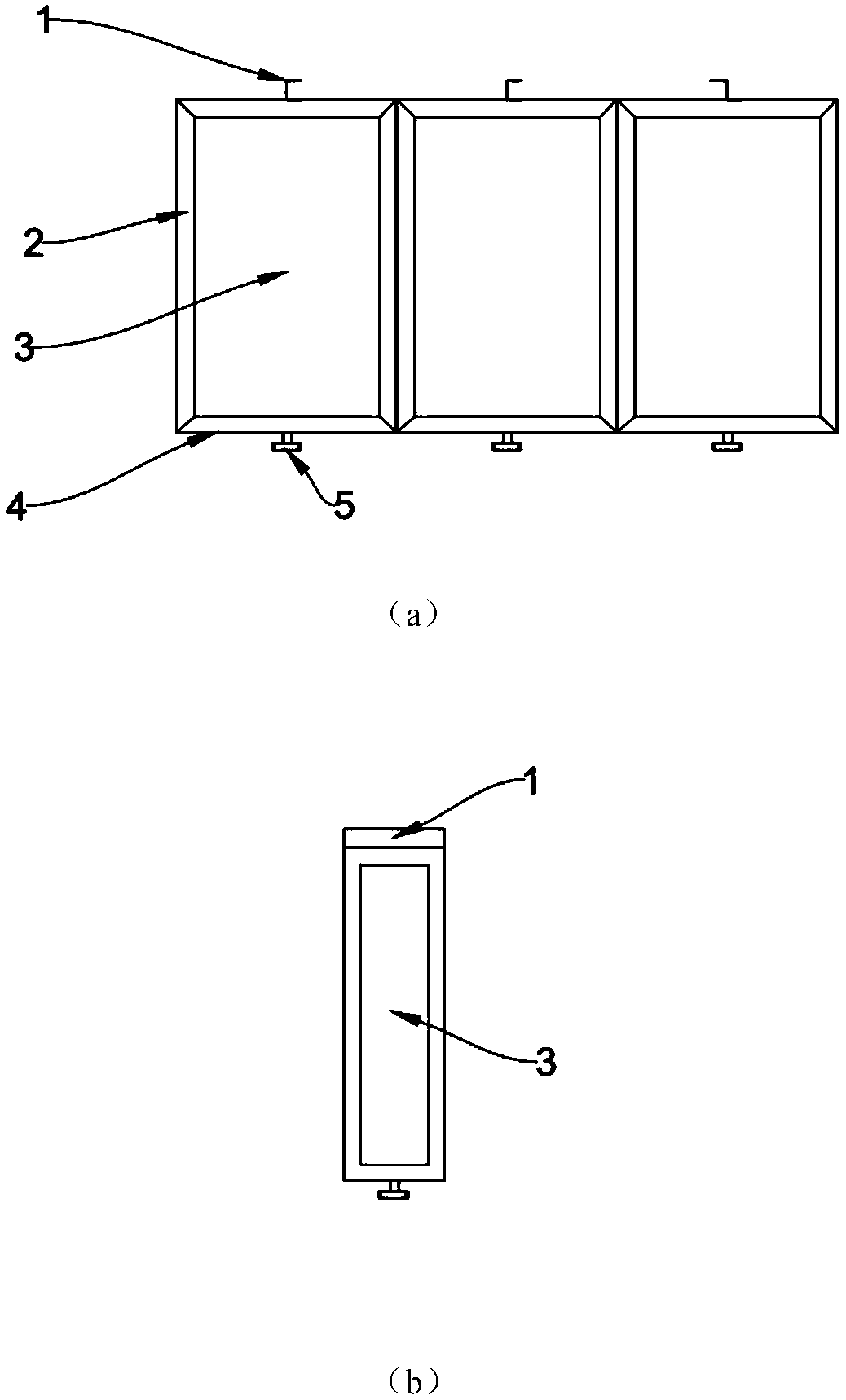

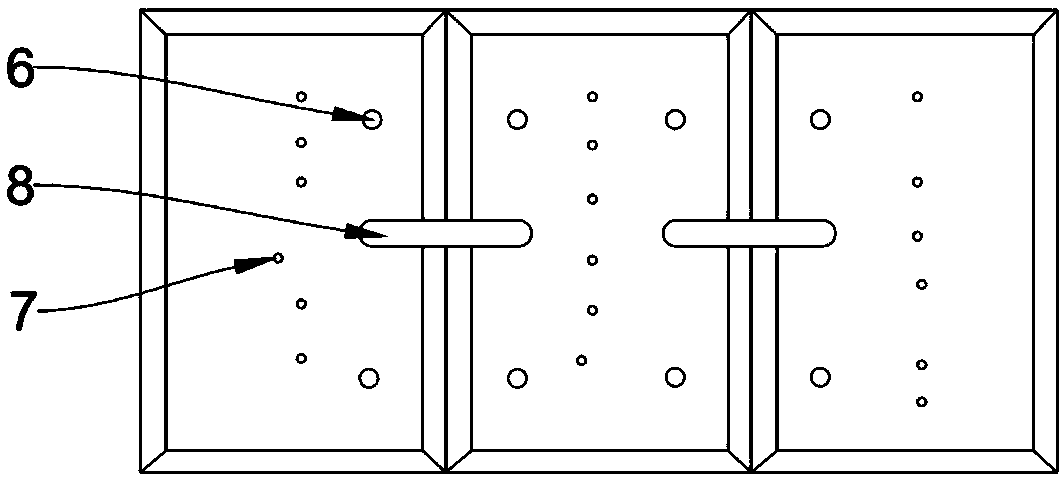

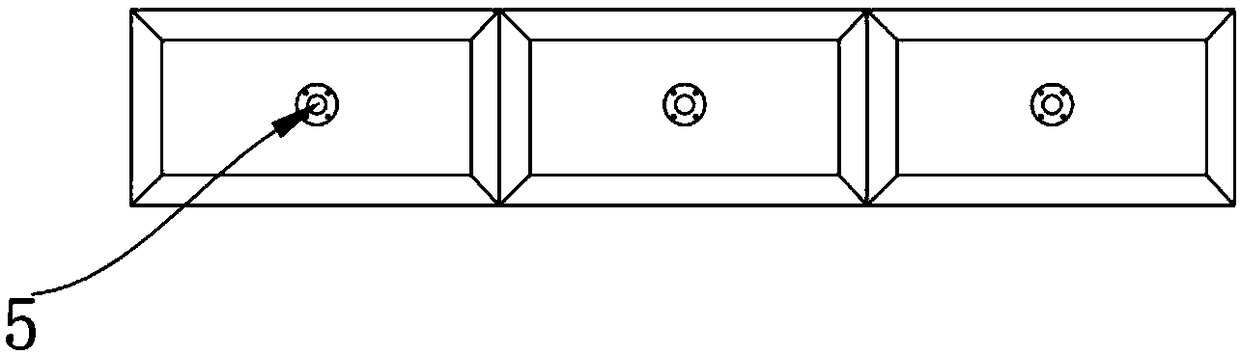

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 of the present invention, ammonia nitrogen content 10mg / L in the sewage flows through three reaction tanks successively, and when flowing into the first reaction tank, the suspended solids and microbial flocs in the water settle due to gravity, remove insoluble substances, and the hydraulic retention time 1h. When the sewage flows through the second reaction tank, add Mg-containing 2+ and PO 3- Ionic agent, make the ammonia nitrogen and phosphorus in the sewage to be replaced by struvite (magnesium ammonium phosphate, MgNH 4 P0 4 ·6H 2 0) in the form of precipitation, thereby recovering nitrogen and phosphorus in the sewage at the same time, and the hydraulic retention time is 2h. Sewage flows into the third reaction tank, and bio-microcapsules are added to the reaction tank to ensure that the dosage of bio-microcapsules is calculated according to the volume of the device. The unit dosage is 0.3g / m 3 , hydraulic retention time 2h. The degradation rate...

Embodiment 2

[0036] Under the same conditions of Example 1, the sewage flowing into the first reaction tank was changed from removing suspended solids through gravity sedimentation to sieving and intercepting, and the grid hole was 5mm. A fine screen is added to the reaction tank, and the retention is carried out through the screen. The degradation to ammonia nitrogen is 63%.

Embodiment 3

[0038] Under the same conditions of Example 1, the hydraulic retention time becomes 2.5 hours after the sewage flows into the second reaction tank, and the ammonia nitrogen degradation rate reaches 66%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com