Low shock wave sensitivity 3, 4-dinitrofurazanofuroxan (DNTF) and preparation method thereof

A technology of shock wave and process method, which is applied in the direction of offensive equipment, single substance as explosive, organic chemistry, etc., and can solve the problems of shock wave sensitivity, low mechanical sensitivity and high molding density not involved in DNTF

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] This embodiment is carried out with reference to the following composition by weight percentage: 99.5% DNTF crude product, the solvent is 98% concentrated sulfuric acid, and 1% calcium stearate. The preparation method of the present embodiment is as follows:

[0020] 100g level preparation process:

[0021] (1) DNTF dissolved

[0022] Weigh 100g of DNTF crude product and 400g of 98% concentrated sulfuric acid, put them in a 1000mL flask, turn on the mechanical stirring rate to 500r / m, heat in a water bath to 80°C-85°C, and stir at this temperature for 20min.

[0023] (2) DNTF morphology control

[0024] Add 1g of CS, continue to stir for 10min at 80°C to 85°C, and the stirring rate is 1000r / m;

[0025] (3) DNTF crystal precipitation

[0026] Stop heating, reduce the stirring rate to 800r / m, and naturally cool down at room temperature from 20°C to 25°C, and keep it warm for 10 minutes when it reaches 63.5°C to 64°C; strictly control the temperature of the crystalliza...

Embodiment 2

[0032] This embodiment is carried out with reference to the following composition by weight: 99.5% crude DNTF, solvent 98% concentrated sulfuric acid, and 1% sodium dodecylsulfonate. The preparation method of this embodiment refers to embodiment 1.

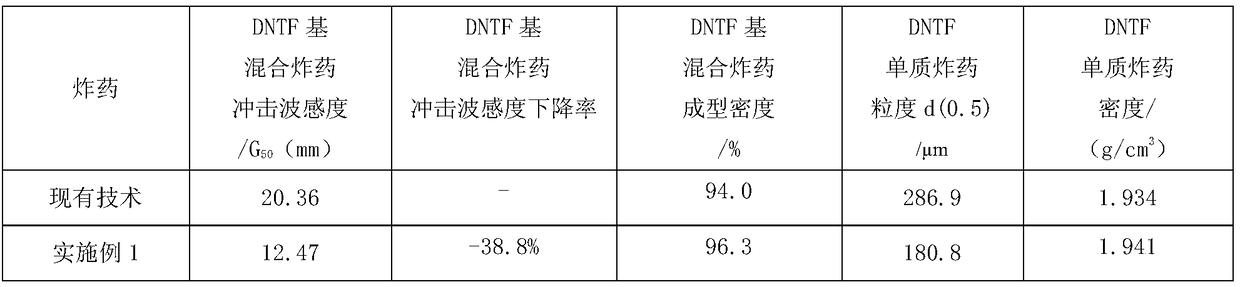

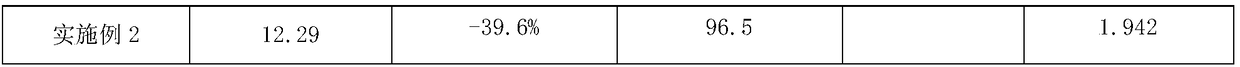

[0033] Table 1 embodiment performance data

[0034]

[0035]

[0036] It can be seen from the above table that the particle size of the low-shock-wave-sensitivity DNTF elemental explosive prepared by the method of the present invention is reduced and relatively uniform, and the density is slightly improved. Compared with the prior art, the shock wave sensitivity of the mixed explosive based on the DNTF single-substance explosive is significantly reduced, the safety is improved, and the molding density is increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com