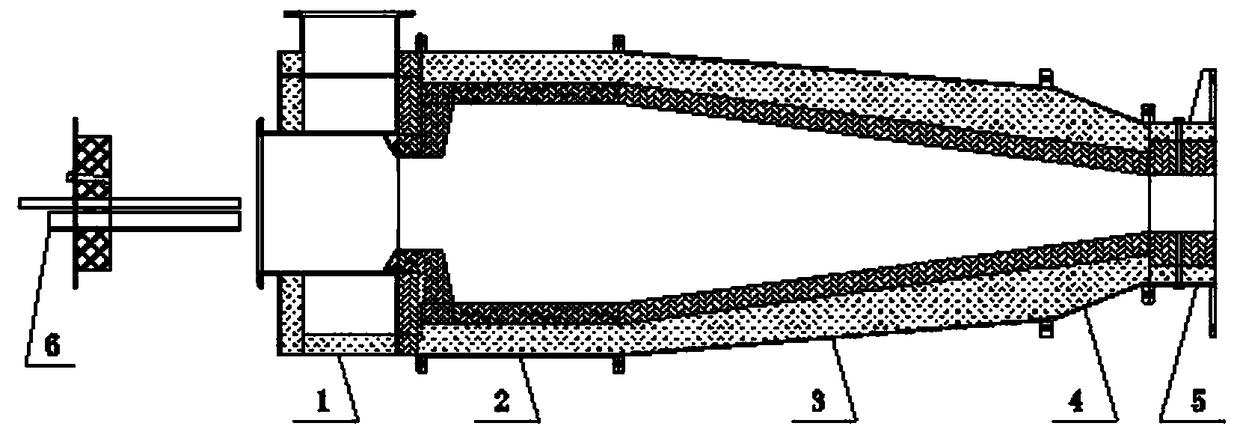

Novel hard carbon black reaction furnace

A technology of hard carbon black and reaction furnace, applied in fibrous fillers and other directions, can solve the problems of low output ratio, increased production cost, insufficient tinting strength, etc., to reduce production cost, prolong service life, and achieve high compression oil absorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

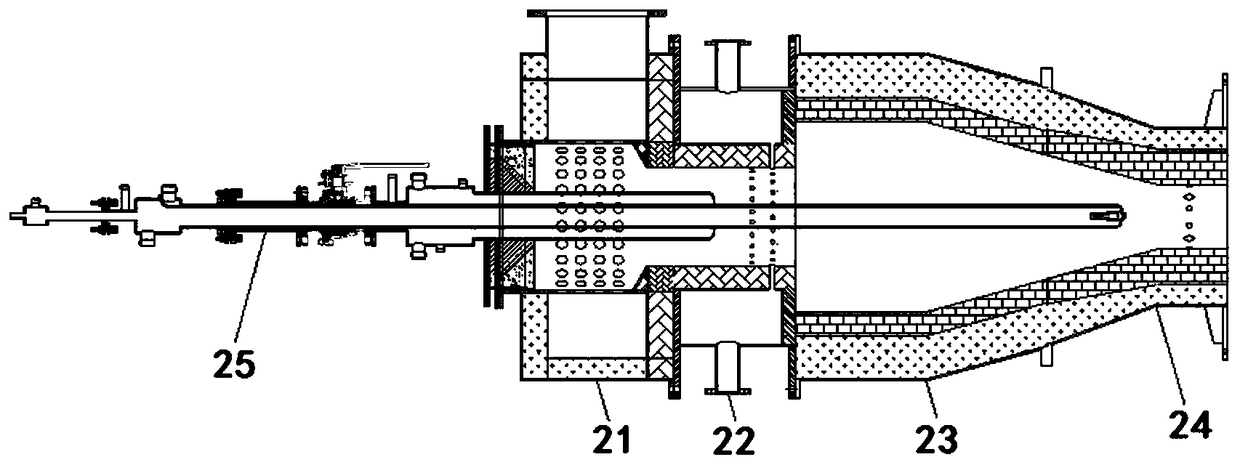

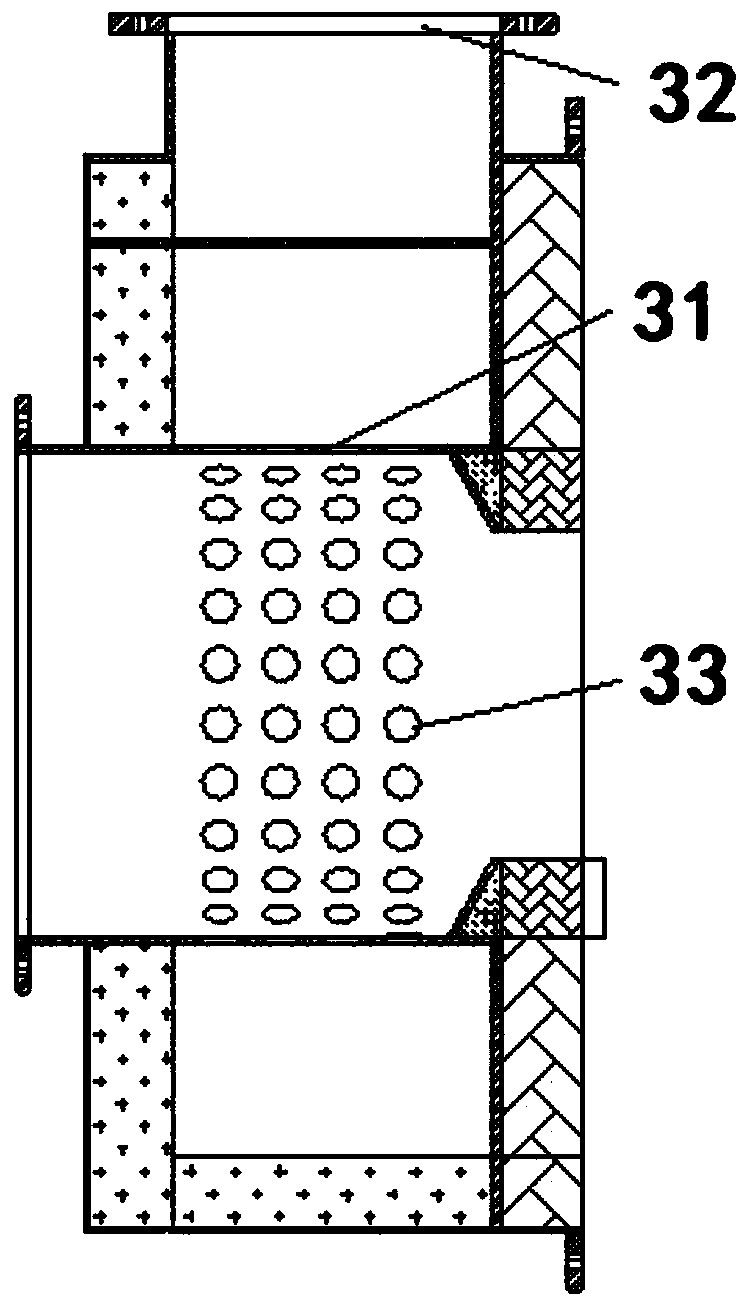

[0024] Such as figure 2 Shown, the present invention is achieved in this way, a kind of novel hard carbon black reaction furnace, described air distributor 21, gas distributor 22, combustion section 23 and throat pipe straight section 24 are axially coaxially sealed and connected to form carbon black Reaction furnace body, the panel central position of described carbon black reaction furnace body is axially provided with raw material oil gun 25, and the muzzle of described raw material oil gun 25 goes deep into the front 200-300mm place of throat straight section; Part of the raw material oil ejected from the oil gun participates in combustion to further increase the reaction temperature, which helps the rest of the raw material oil to be cracked to obtain high-quality carbon black products, and the distance can meet the sufficient occurrence of combustion and reaction processes, and the ejected raw material oil does not The side wall of the reaction furnace will be scoured t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com