A kind of grinding liquid for mirror surface treatment of steel mold surface and using method

A technology of mirror surface treatment and surface treatment, which is applied in the field of grinding fluid, can solve the problems of poor treatment effect, achieve good treatment effect, strengthen the mirror surface effect, and reduce the effect of mirror surface treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

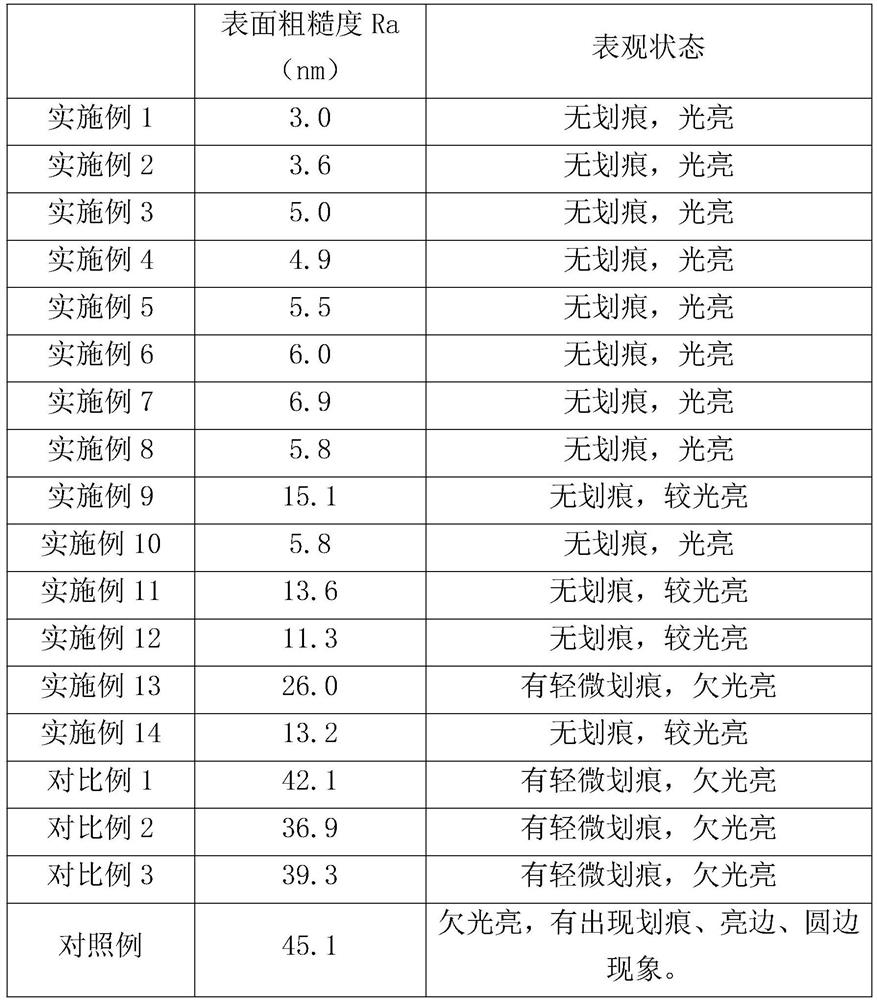

Examples

Embodiment 1

[0055] A kind of lapping fluid that is used for steel mold surface mirror surface treatment of the present embodiment, its raw material comprises following components by weight:

[0056] 2.5μm natural diamond powder: 4.5 parts,

[0057] 0.15μm natural diamond powder: 5.5 parts,

[0058] Glycerol: 1.3 parts,

[0059] 0.15μm single crystal diamond powder: 1.8 parts,

[0060] Stearic acid: 0.4 parts,

[0061] Deionized water: 86 parts.

[0062] The grinding liquid of present embodiment 1 is used for DC53 steel mold surface, and its preparation method for use comprises the following steps:

[0063] (1) Heat deionized water to 70°C.

[0064] (2) Add stearic acid and glycerin into deionized water, stir evenly and cool to 20-25°C.

[0065] (3) Add 2.5 μm natural diamond powder to the solution obtained in step (2), and stir evenly to obtain a coarse grinding liquid.

[0066] (4) Put the DC53 steel mold into the mold slot according to the direction that the grinding surface needs ...

Embodiment 14

[0073] The grinding liquid formula composition of embodiment 14 is exactly the same as embodiment 1, namely:

[0074] 2.5μm natural diamond powder: 4.5 parts,

[0075] 0.15μm natural diamond powder: 5.5 parts,

[0076] Glycerol: 1.3 parts,

[0077] 0.15μm single crystal diamond powder: 1.8 parts,

[0078] Stearic acid: 0.4 parts,

[0079] Deionized water: 86 parts.

[0080] The lapping liquid of embodiment 14 is used for the DC53 steel mold surface of the same batch as embodiment 1, and its preparation method for use comprises the following steps:

[0081] (1) Heat deionized water to 70°C.

[0082] (2) Add stearic acid and glycerol into hot deionized water, stir evenly and cool to 20-25°C.

[0083] (3) Add 2.5 μm natural diamond powder, 0.15 μm natural diamond powder, and single crystal diamond powder into the solution, and stir evenly to obtain a grinding liquid.

[0084] (4) Put the DC53 steel mold with the surface to be ground down, and put it into the mold slot to m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com