A kind of hydrated sulfate composite phase change material and preparation method thereof

A composite phase change material and sulfate technology, which is applied in the field of hydrated sulfate composite phase change materials and its preparation, can solve the problems of weak temperature sensitivity and narrow phase transition temperature range, and achieve high phase transition latent heat and phase transition temperature wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

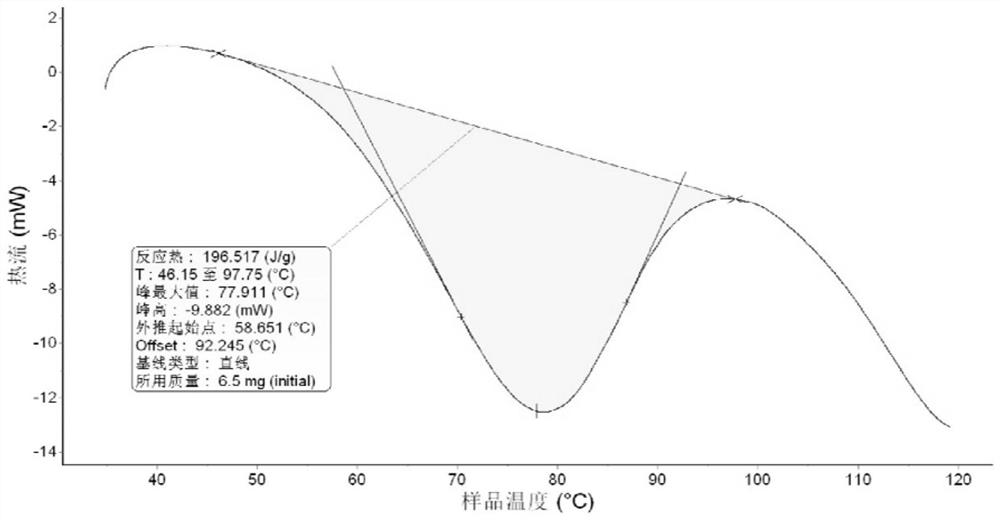

Embodiment 1

[0040] Accurately weigh 18g of aluminum sulfate octadecahydrate, 10.5g of ammonium aluminum sulfate dodecahydrate and 1.5g of potassium aluminum sulfate dodecahydrate and mix manually, and then add 0.15g of white clay, 0.3g of carboxymethylcellulose and 0.6g of graphite. Put the above mixture into a ball mill tank, add 4ml of deionized water to carry out wet ball milling for 1 hour, control the speed of the ball mill to 15-25 rpm, put the mixture A obtained by ball milling into a reaction kettle, melt and stir at 110°C for 0.5 h, after adding 0.6 g of potassium hydroxide thereto, continue stirring for 0.5 h to adjust and maintain the pH between 3 and 4 to obtain molten mixture B. The molten mixture B was lowered to 60°C in the reaction kettle and continued to stir for about 1 hour to complete the recrystallization to obtain the solid mixture C. After that, it was washed and purified with deionized water for 3 times, each time using 72ml of deionized water, and then dried at 60°...

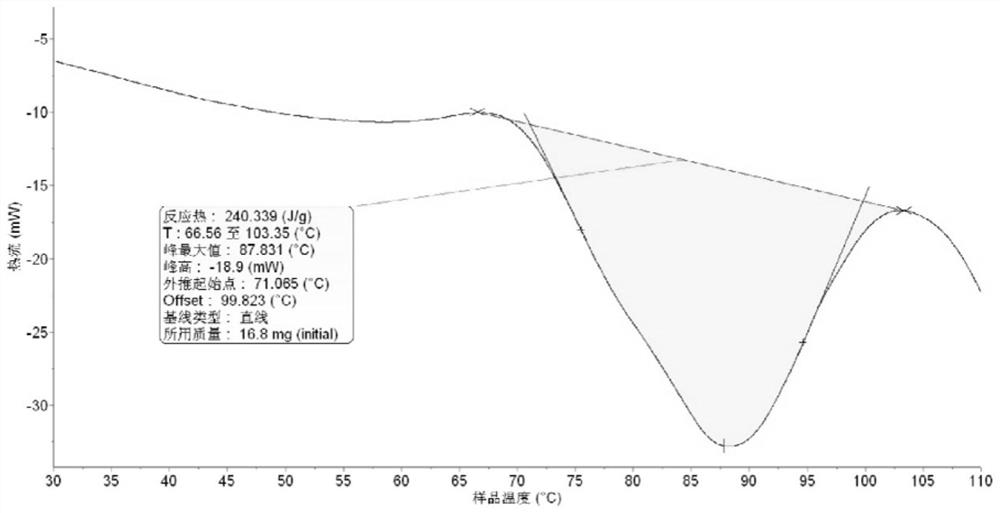

Embodiment 2

[0042] Accurately weigh 16.5g of aluminum sulfate octadecahydrate, 9g of ammonium aluminum sulfate dodecahydrate and 4.5g of potassium aluminum sulfate dodecahydrate and mix manually, then add 0.15g of clay, 0.3g of carboxymethylcellulose and 0.6g of graphite. Put the above mixture into a ball mill tank and add 4ml of deionized water to carry out wet ball milling for 1 hour, control the speed of the ball mill to 15-25 rpm, put the mixture A obtained by ball milling into a reaction kettle, melt and stir at 120°C for 0.5 h, after adding 0.9 g of potassium hydroxide thereto, continue stirring for 0.5 h to adjust and maintain the pH between 3 and 4 to obtain molten mixture B. The molten mixture B was lowered to 65°C in the reaction kettle and continued to stir for about 1 hour to complete the recrystallization to obtain the solid mixture C. After that, it was washed and purified with deionized water for 3 times, each time using 72ml of deionized water, and then dried at 60°C Obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com