A Composite Emulsifier and Its Application in Production of Microemulsion Diesel Oil

A compound emulsifier and micro-emulsification technology, which is used in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve the problems of difficult commodities, turnover use, only ten days or half a month, etc., and achieves the reduction of exhaust smoke. , the effect of reducing production costs and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Embodiment 1: the preparation of composite emulsifier

[0071] 1. Pretreatment of waste oil:

[0072] The waste oil is mechanically filtered to remove impurities. Add 4% chemical oxidizing agent accounting for waste oil weight, and heat to 75°C. Stir the reaction for 20 minutes, and centrifuge to remove water and a small amount of unreacted chemical oxidant.

[0073] Formulation of chemical oxidizing agents:

[0074] 3 parts of hydrogen peroxide, 1 part of sodium percarbonate, 0.001 part of titanium salt.

[0075] Mix and stir evenly at room temperature.

[0076] 2. Methylation modification of waste oil:

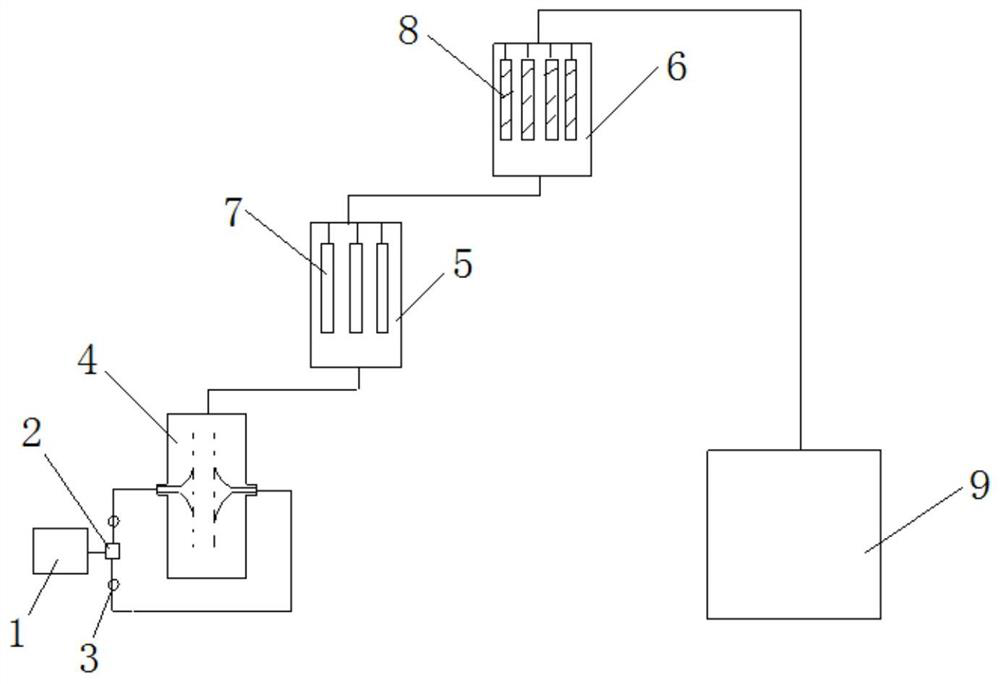

[0077] In the continuous flow reaction system of the present invention ( figure 1 ) for methyl esterification modification.

[0078] The waste oil after pretreatment is put into batching tank 1 earlier, then will account for the waste oil after the pretreatment waste oil weight 20% to be dissolved with the methyl alcohol that catalyst metal sodium is added in t...

Embodiment 2

[0081] Embodiment 2: the preparation of microemulsion diesel oil

[0082] 1. Raw material composition:

[0083] 80 parts of diesel oil, 10 parts of water, 6.5 parts of composite emulsifier, 2.5 parts of solubilizing agent, 0.8 parts of stabilizer, and 0.02 parts of water splitting catalyst.

[0084] Wherein, the composite emulsifier is prepared by Example 1; the solubilizing water agent is mixed by n-propanol, n-butanol and n-amyl alcohol in a volume ratio of 0.5:1:0.5; the stabilizer is castor oil methyl ester amide, made of castor oil The sesame oil is prepared in the continuous flow reaction system of the present invention; the water splitting catalyst is composed of titanate and permanganate in a mass ratio of 1:1.

[0085] 2. Preparation process:

[0086] Put diesel oil, water, compound emulsifier, solubilizer, stabilizer and water splitting catalyst into the batching tank, stir at room temperature for 3-5 minutes, mix well, start the centrifugal pump, and pass the mixe...

Embodiment 3

[0087] Embodiment 3: the preparation of microemulsion diesel oil:

[0088] 1. Raw material composition:

[0089] 72 parts of diesel oil, 12 parts of water, 7 parts of composite emulsifier, 3.5 parts of solubilizing agent, 0.5 part of stabilizer, and 0.05 part of water splitting catalyst.

[0090] Wherein, the composite emulsifier is prepared by Example 1; the solubilizing water agent is mixed by n-propanol, n-butanol and n-amyl alcohol in a volume ratio of 0.5:1:0.5; the stabilizer is castor oil methyl ester amide, made of castor oil The sesame oil is prepared in the continuous flow reaction system of the present invention; the water splitting catalyst is composed of titanate and permanganate, and the mass ratio of the two is 1:1.

[0091] 2. The preparation process is the same as in Example 2, and the microemulsion diesel oil is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com