Low-hair-containing Tencel polyester blended fabric and preparation method thereof

A technology of blended fabrics and wool tencel, applied in the field of fabric weaving, can solve the problems of easy shrinkage, cumbersome dyeing process, and high cost, and achieve the effects of increasing dyeing rate, saving water resources, and improving melting resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

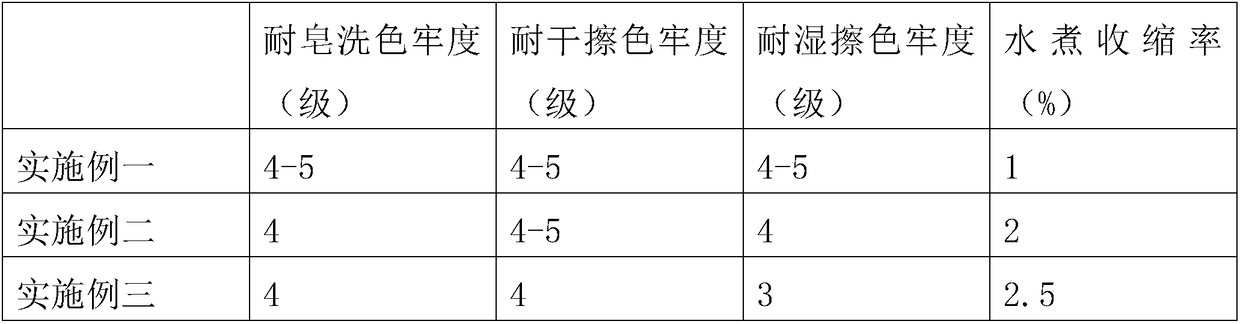

Examples

Embodiment 1

[0037] A low-hair tencel blended fabric, made of wool fiber, tencel and polyester fiber as raw materials; in terms of raw material weight percentage, the content of each raw material component in the finished fabric is: 64S fine short hair 5%, 70S short hair 10% loose wool, 5% loose wool 80S, 50% Tencel 33D / 10F, 15% ordinary polyester fiber 30D / 18F, 15% cationic polyester fiber 30D / 18F.

[0038] A low-hair tencel blended fabric and a preparation method thereof, comprising the following steps:

[0039] S1. Ingredients: 64S fine short hair, 70S loose wool, 80S loose wool, 33D / 10F tencel, 30D / 18F ordinary polyester fiber, 30D / 18F cationic polyester after treatment with the treatment liquid The fibers are weighed and mixed according to the weight percentages of 5%, 10%, 5%, 50%, 15%, and 15%, respectively;

[0040] Described cationic polyester fiber and ordinary polyester fiber are pre-processed through the following steps before batching:

[0041] (1) 10 parts by weight of epox...

Embodiment 2

[0057] A low-hair tencel blended fabric, made of wool fiber, tencel and polyester fiber as raw materials; in terms of raw material weight percentage, the content of each raw material component in the finished fabric is: 64S short hair 10%, 70S short hair 5% loose wool, 10% loose wool 80S, 45% Tencel 33D / 10F, 10% ordinary polyester fiber 30D / 18F, 20% cationic polyester fiber 30D / 18F.

[0058] A low-hair tencel blended fabric and a preparation method thereof, comprising the following steps:

[0059] S1. Ingredients: 64S fine short hair, 70S loose wool, 80S loose wool, 33D / 10F tencel, 30D / 18F ordinary polyester fiber, 30D / 18F cationic polyester after treatment with the treatment liquid The fibers are weighed and mixed according to the weight percentages of 10%, 5%, 10%, 45%, 10%, and 20%, respectively;

[0060] S2. Spinning: including opening and mixing in a wool machine, opening and removing impurities with a cleaning machine, carding with a carding machine to obtain wool tops,...

Embodiment 3

[0074] A low-hair Tencel blended fabric, made of wool fiber, Tencel, and polyester fiber as raw materials; in terms of raw material weight percentage, the content of each raw material component in the finished fabric is: 64S short hair 8%, 70S short hair 8% loose wool, 8% loose wool 80S, 46% Tencel 33D / 10F, 20% ordinary polyester fiber 30D / 18F, 10% cationic polyester fiber 30D / 18F.

[0075] A low-hair tencel blended fabric and a preparation method thereof, comprising the following steps:

[0076] S1. Ingredients: 64S fine short hair, 70S loose wool, 80S loose wool, 33D / 10F tencel, 30D / 18F ordinary polyester fiber, 30D / 18F cationic polyester after treatment with the treatment liquid The fibers are weighed and mixed according to the weight percentages of 8%, 8%, 8%, 46%, 20%, and 10%, respectively;

[0077] S2. Spinning: including opening and mixing in a wool machine, opening and removing impurities with a cleaning machine, carding with a carding machine to obtain wool tops, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com