Automobile engine exhaust waste heat recoverer and method

A technology of automobile engine and exhaust waste heat, which is applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems of heat pollution in the surrounding environment and the exhaust heat energy utilization rate of the waste heat recovery device is not very high, so as to reduce the discharge rate, Reduced cross-sectional area and high heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

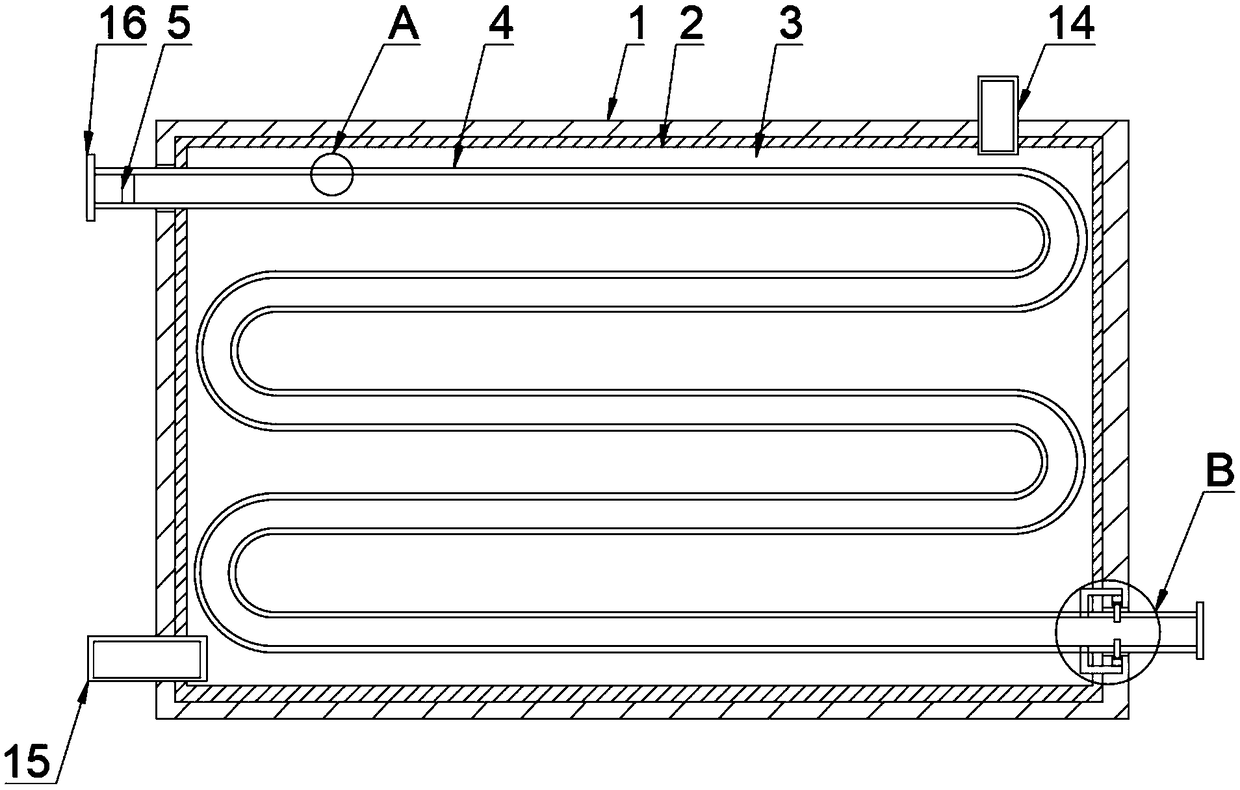

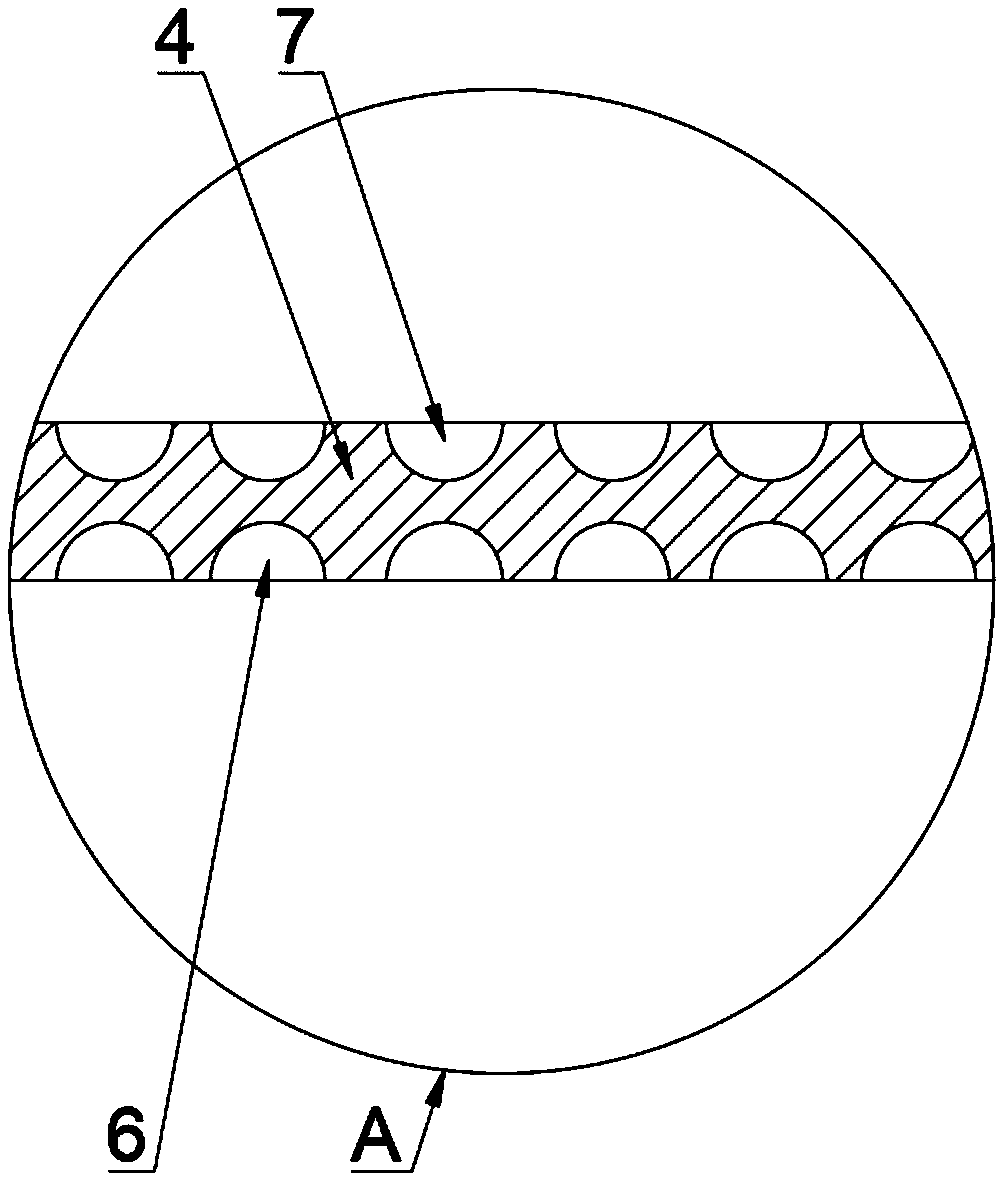

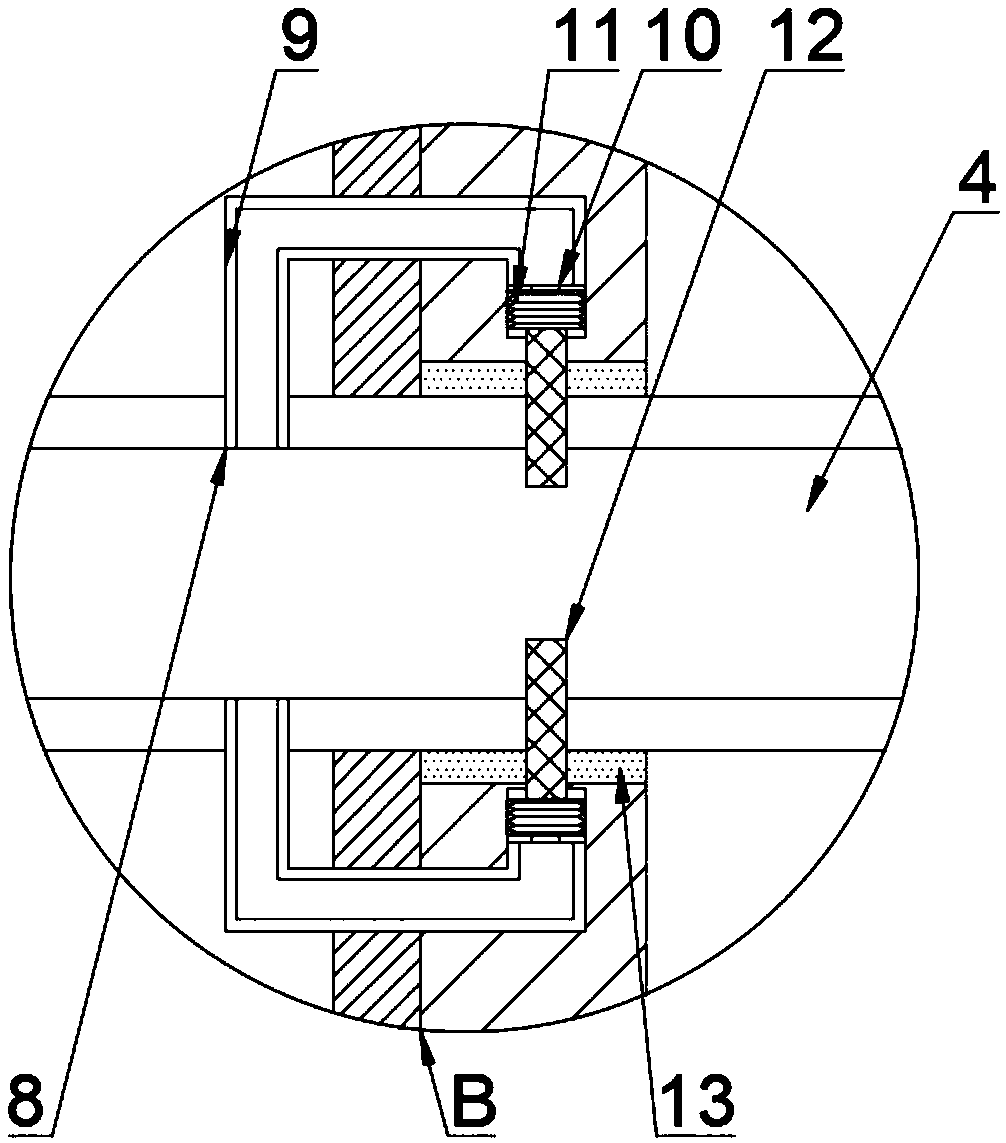

[0024] The present invention provides such Figure 1-3 The exhaust waste heat recovery device of an automobile engine as shown includes a casing 1, the inner wall surface of the casing 1 is provided with a heat insulating layer 2, the inner side of the heat insulating layer 2 is provided with a water storage bin 3, and the inside of the water storage bin 3 is provided with a trachea 4. One end of the trachea 4 is provided with a filter layer 5, the inner wall surface of the trachea 4 is provided with an inner groove 6, the outer wall surface of the trachea 4 is provided with an outer groove 7, and the other end of the trachea 4 is provided with an opening 8, The top of the opening 8 is provided with an air guide tube 9, one end of the air guide tube 9 is provided with an air outlet 10, one end of the air outlet 10 is provided with an elastic air bag 11, and one end of the elastic air bag 11 is provided with an air limiting plate 12, and the air limiting plate 12 is provided at ...

Embodiment 2

[0034] A method for recovering exhaust waste heat of an automobile engine, comprising the exhaust waste heat recovery device of an automobile engine, further comprising the following steps:

[0035] S1: Cold water is installed in the water storage tank 3, and the exhaust gas discharged from the engine enters from one end of the air pipe 4. The filter layer 5 made of activated carbon in the air pipe 4 filters out the solid particles in the exhaust gas, and the air pipe 4 made of a copper tube absorbs the heat energy in the exhaust gas. pass it on;

[0036] S2: The multiple inner grooves 6 on the inner wall surface of the air pipe 4 increase the contact area with the exhaust gas, and the multiple outer grooves 7 on the outer wall surface increase the contact area between the air pipe 4 and the cold water, and a small part of the exhaust gas passes through the air guide pipe 9 from the air outlet 10 is discharged into the elastic air bag 11;

[0037] S3: the elastic airbag 11 ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com