Piston phase-adjusted pulse tube refrigerator connected with compression piston through spring

A technology of pulse tube refrigerator and spring connection, applied in refrigerators, compressors, gas cycle refrigerators, etc., can solve problems such as difficult control or adjustment, complex system, etc., and achieve improved refrigeration performance, small size, and increased regulation The effect of phase range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

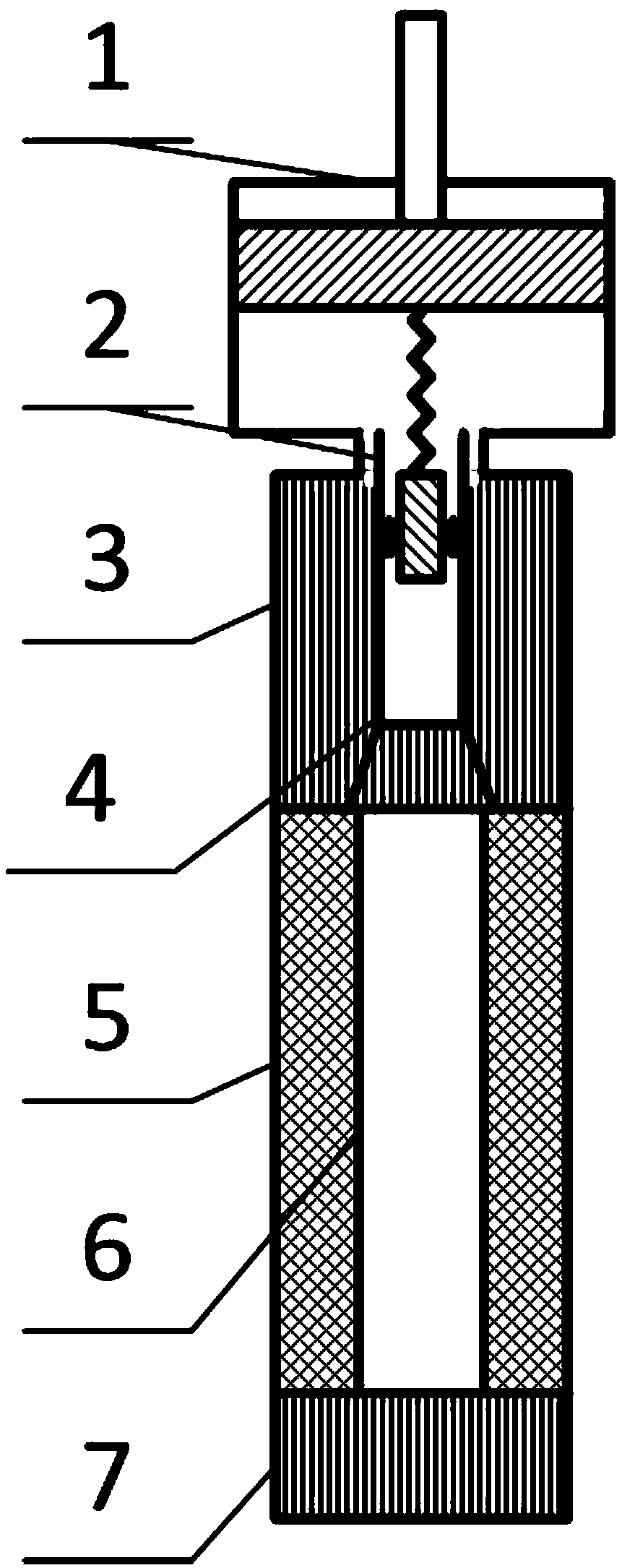

[0043] Such as figure 1 and 2 As shown, the piston-tuned coaxial pulse tube refrigerator connected by a spring to the piston of the compressor in this embodiment includes a compressor module 1, a regenerator hot-end heat exchanger 3, a regenerator 5, and a cold-end exchanger connected in sequence. Heater 7, pulse tube 6, heat exchanger 4 at the hot end of the pulse tube, and phase modulation module 2.

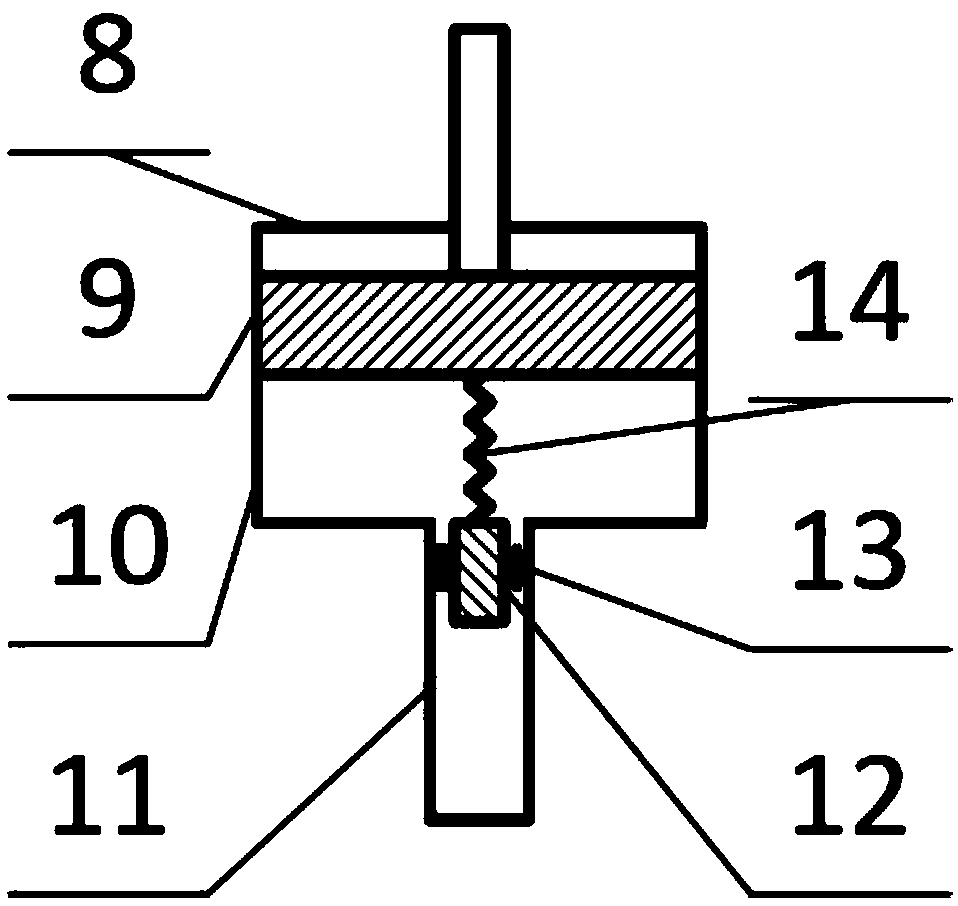

[0044] Wherein, the compressor module 1 includes a back pressure chamber 8 , a compressor piston 9 and a compression chamber 10 . The phasing module 2 includes an expansion chamber 11 , a phasing piston 12 , a sealing gap 13 and a spring 14 . The compression chamber 10 communicates with the heat exchanger 3 at the hot end of the regenerator, and the expansion chamber 11 communicates with the heat exchanger 4 at the hot end of the pulse tube. The spring 14 is located in the compression chamber 10 and connects the compressor piston 9 and the phase adjustment piston 12 .

[0045...

Embodiment 2

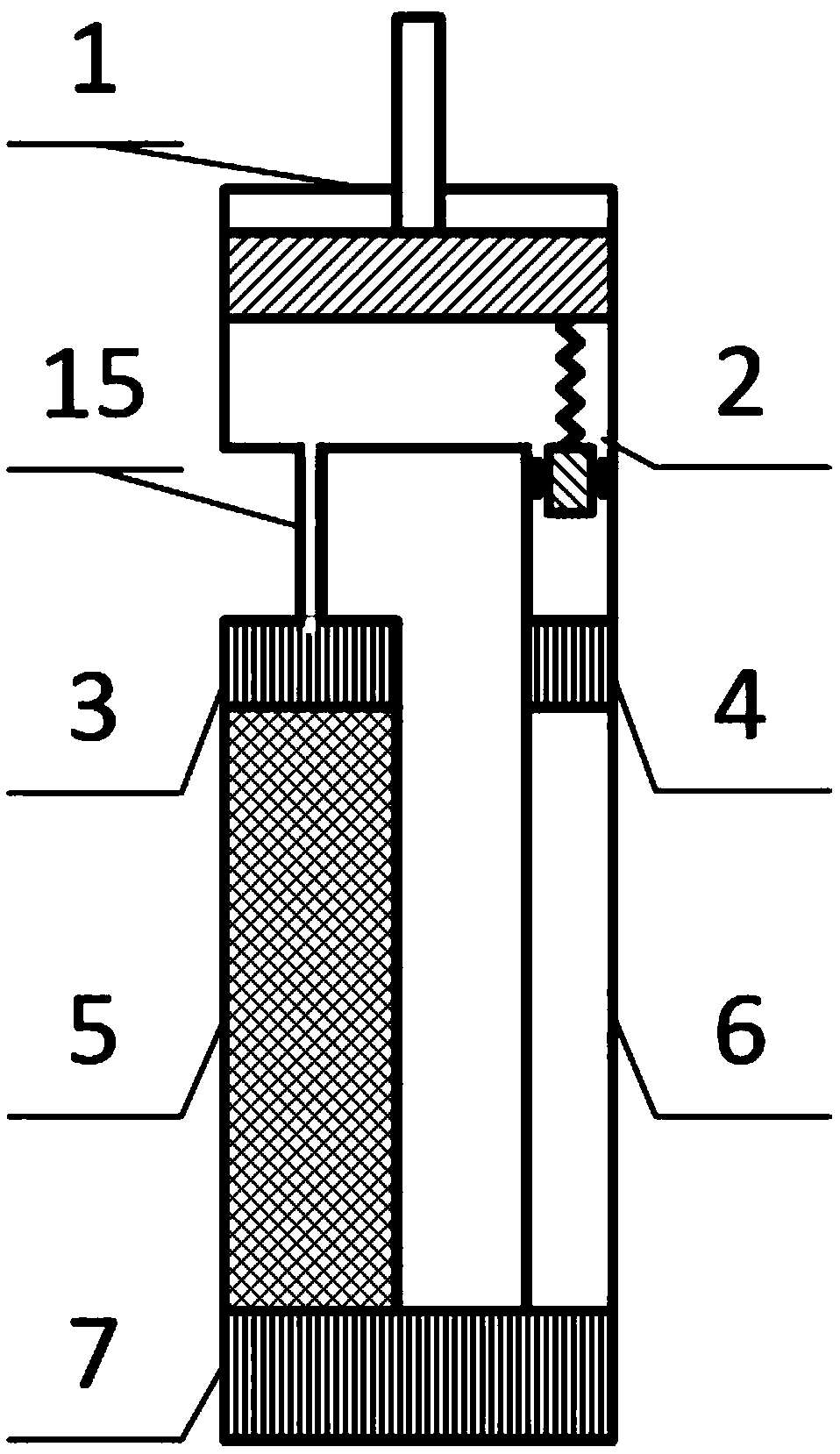

[0048] Such as image 3 As shown, in this embodiment, the piston phasing U-shaped pulse tube refrigerator is connected by a spring to the piston of the compressor. The regenerator 5 is arranged in parallel with the pulse tube 6 and communicated with the cold end heat exchanger 7. The expansion chamber 11 is connected to the pulse tube The hot end heat exchanger 4 communicates, and the compression chamber 10 communicates with the regenerator hot end heat exchanger 3 through a connecting pipe 15 . All the other structures are the same as in Example 1.

Embodiment 3

[0050] Such as Figure 4 As shown, in the piston-tuned coaxial pulse tube refrigerator in which the piston of the compressor is connected by springs in this embodiment, the regenerator 5 and the pulse tube 6 are coaxially arranged. The compressor module 1 contains two back pressure chambers 8 and two compressor pistons 9, which are arranged symmetrically. The phasing module 2 includes two phasing pistons 12 , which are respectively connected to the two compressor pistons 9 through springs 14 . The compression chamber 10 communicates with the heat exchanger 3 at the hot end of the regenerator, and the expansion chamber 11 communicates with the heat exchanger 4 at the hot end of the pulse tube through a connecting pipe 15 . All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com