Method and device for detecting surface topography of fixed abrasive grinding tool

A technology of consolidating abrasives and surface topography, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of diffraction, sensitivity to environmental factors, and inability to accurately reflect the actual topography of the abrasive tool surface, and achieve high cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

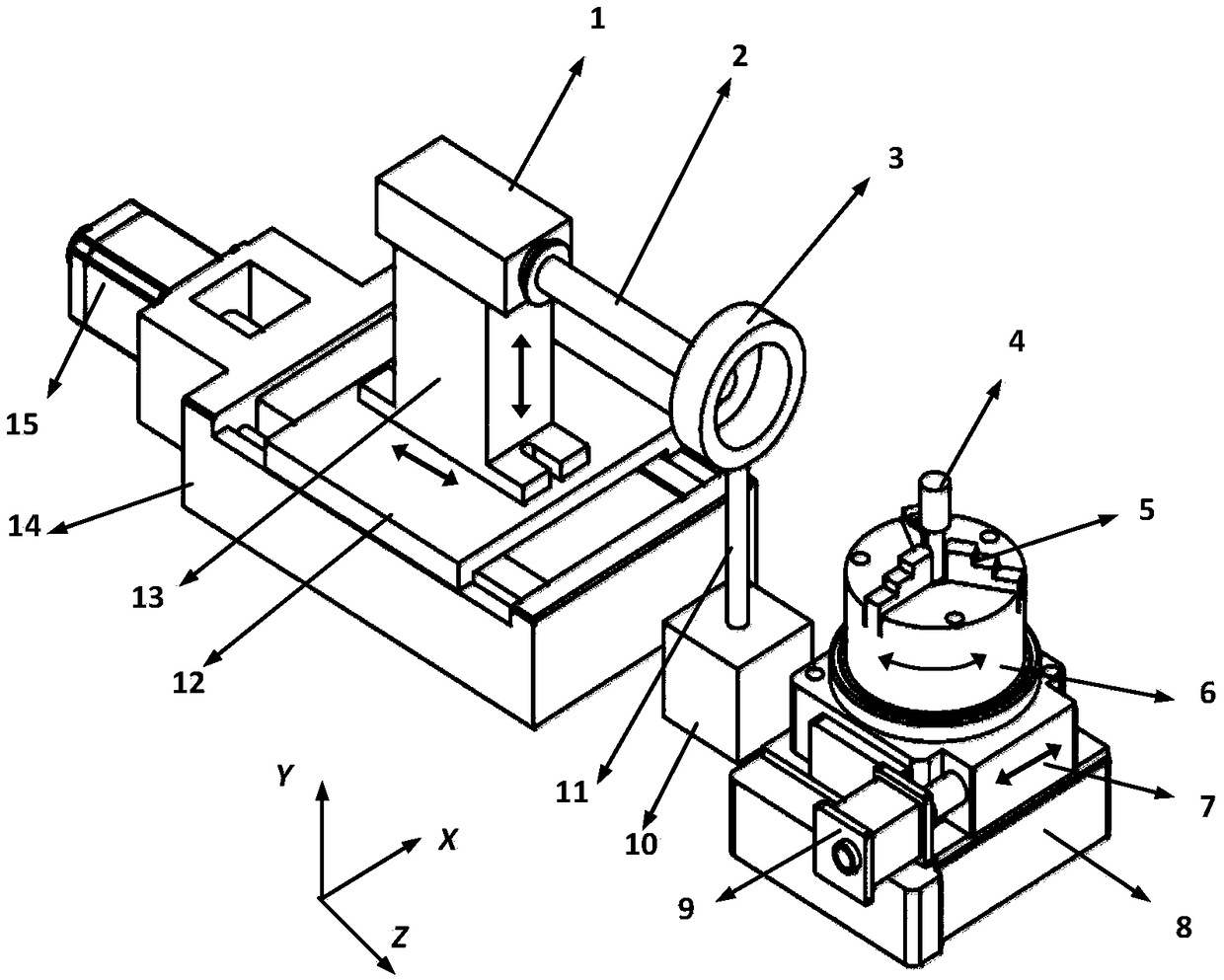

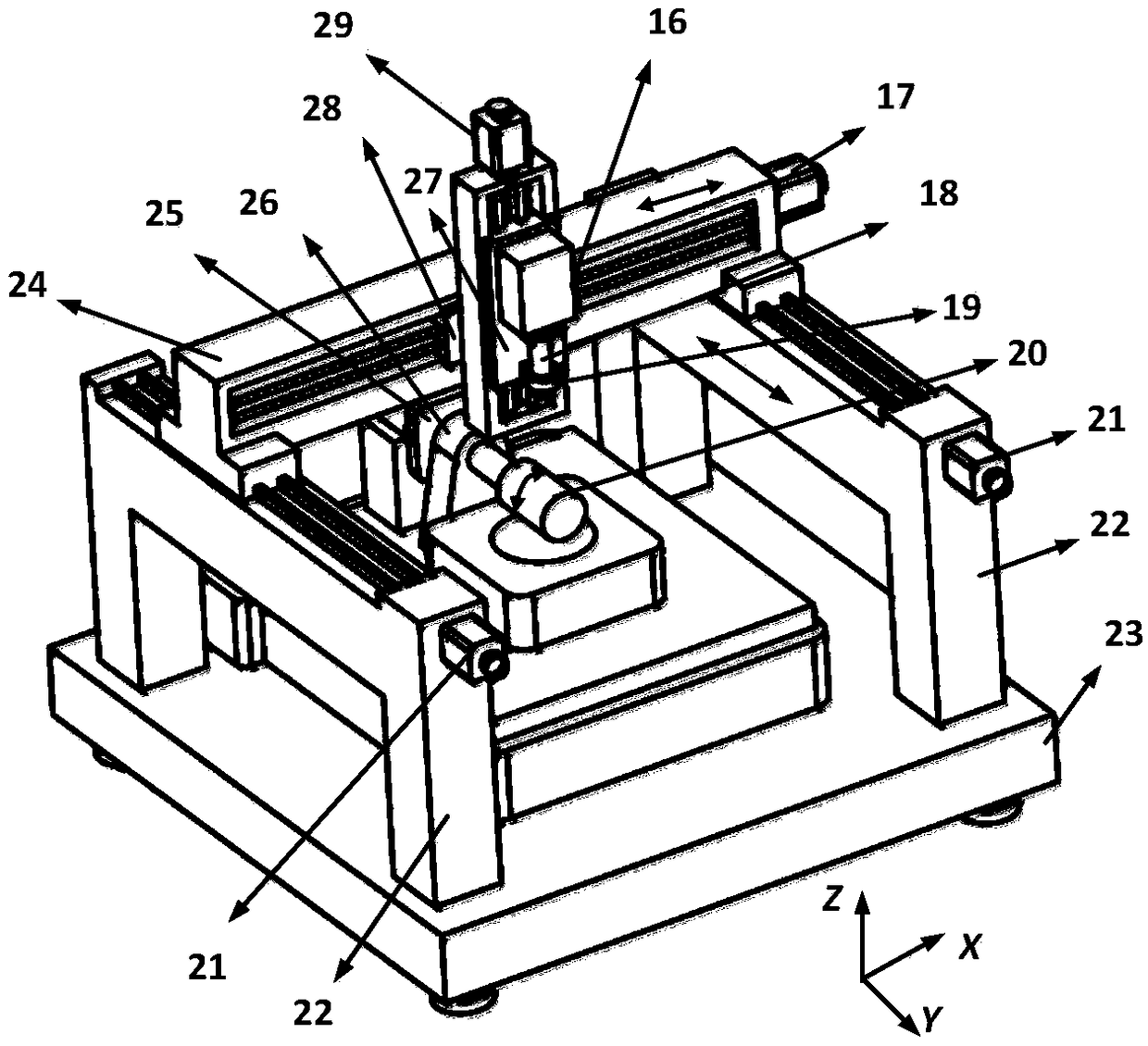

[0038] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0039] The surface topography detection method of the consolidated abrasive tool of the present invention comprises the following steps:

[0040] Step 1. Connect the CCD camera to the computer through the image acquisition card. The CCD camera transmits the screen of the measured bonded abrasive to the computer and displays it on the computer monitor. Change the position of the CCD camera and rotate the measured bonded abrasive so that The CCD camera lens is aimed at the measured surface area of the measured fixed abrasive abrasive;

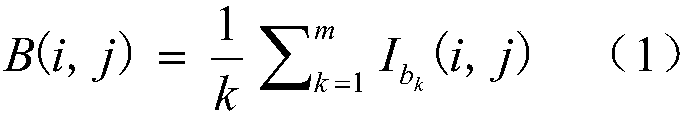

[0041] Step 2: When using the CCD camera to obtain the topography information of the surface of the measured bonded abrasive tool, since a single image can only obtain two-dimensional information of the measured area, it is impossible to directly obtain the complete three-dimensional information ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com