Low-frequency sound field particle velocity sensitive structure and preparation method

A particle vibration velocity and sensitive structure technology, which is applied in the measurement of ultrasonic/sonic/infrasonic waves, measuring devices, instruments, etc., can solve the problems of the lower limit of the effective operating frequency of the sensor, the deterioration of the sensor response characteristics, and the attenuation of sensitivity, so as to improve the response in the low frequency band characteristics, suppression of heat conduction effects, and effect of ensuring response sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

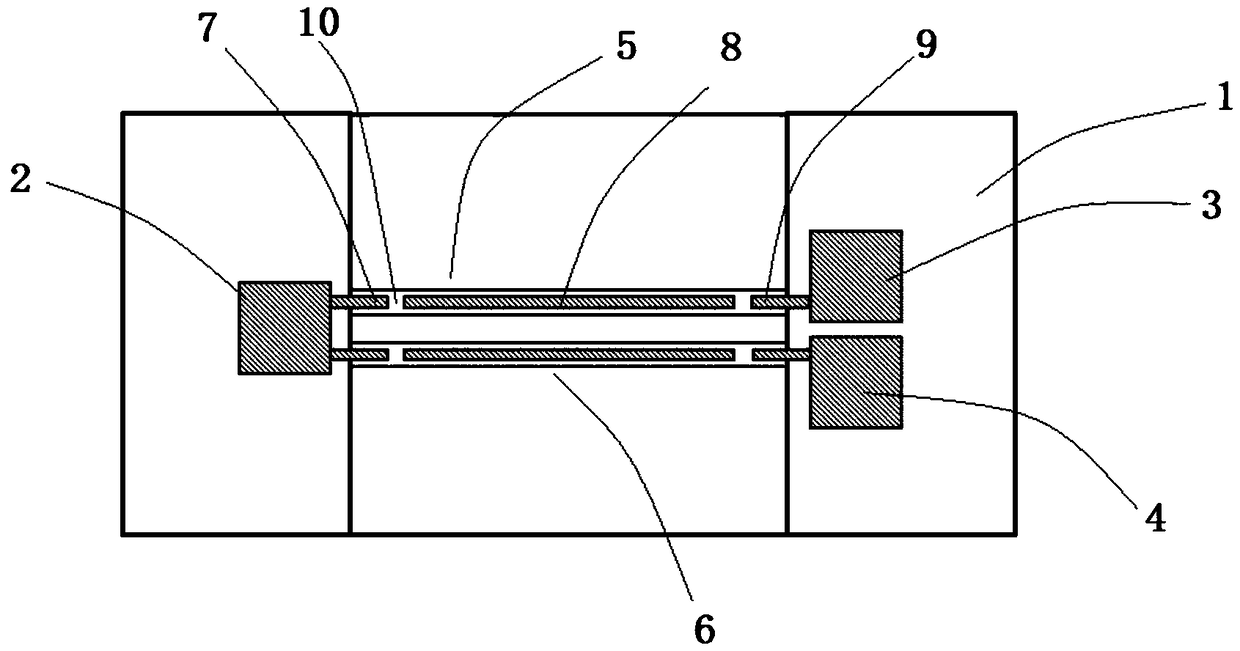

[0032] Such as figure 1 As shown, a bridge hole is formed on the silicon substrate 1, a first electrode 2 is arranged on one side of the bridge hole, a second electrode 3 and a third electrode 4 are arranged on the other side of the bridge hole, and a first thin wire is arranged above the bridge hole. 5. The second thin wire 6, the first thin wire 5, and the second thin wire 6 are arranged in parallel and keep a small distance. One end of the two thin wires is connected to the first electrode 2, and the other ends of the two thin wires are respectively connected to the first electrode 2. The second electrode 3 and the third electrode connection 4 are prior art.

[0033] The structures of the first thin wire 5, the second thin wire 6, the first electrode 2, the second electrode 3 and the third electrode 4 are all composed of a heat insulating layer, a supporting layer, an adhesive layer and a sensitive layer from bottom to top. The sensitive layers of the first thin wire 5 and...

Embodiment 2

[0035] In the second embodiment, a thin wire is arranged between the first thin wire and the second thin wire, and the said one thin wire is arranged in parallel with the first thin wire and the second thin wire, and its structure is the same as that of the first thin wire and the second thin wire. The two thin threads are the same. The thin filaments have a width of 2 μm and a thickness of 0.4 μm. The width of the air gap layer was 0.2 μm. All the other structures of embodiment two are the same as embodiment one.

Embodiment 3

[0037] The preparation method of the low-frequency sound field particle velocity sensitive structure of the present invention comprises the following steps:

[0038] Step 1: If figure 2 As shown, a thermal insulation layer and a support layer are sequentially deposited on a silicon substrate, wherein the thermal insulation layer is located below the support layer;

[0039] Step 2: Carry out the first glue coating, photolithography and development to define the structure of the first electrode, the second electrode, the third electrode, the first thin wire and the second thin wire of the low-frequency sound field particle velocity sensitive structure. Such as image 3 As shown, carry out the first glue application. Such as Figure 4 As shown, the adhesion layer and the sensitive layer are deposited sequentially. Such as Figure 5 As shown, the photoresist is stripped to form the corresponding sensitive structures.

[0040] Step 3: Carry out the second glue coating, photo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com