Magnetic nanoparticle inductance temperature measurement method and device used for electromagnetic heating equipment

A technology of magnetic nanoparticles and heating equipment, which is applied in the direction of using electric devices, thermometers and measuring devices using electric/magnetic elements that are directly sensitive to heat, and can solve the inconvenient use of magnetic temperature measurement technology with penetrating ability, etc. problems, to achieve the effect of offsetting background interference and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

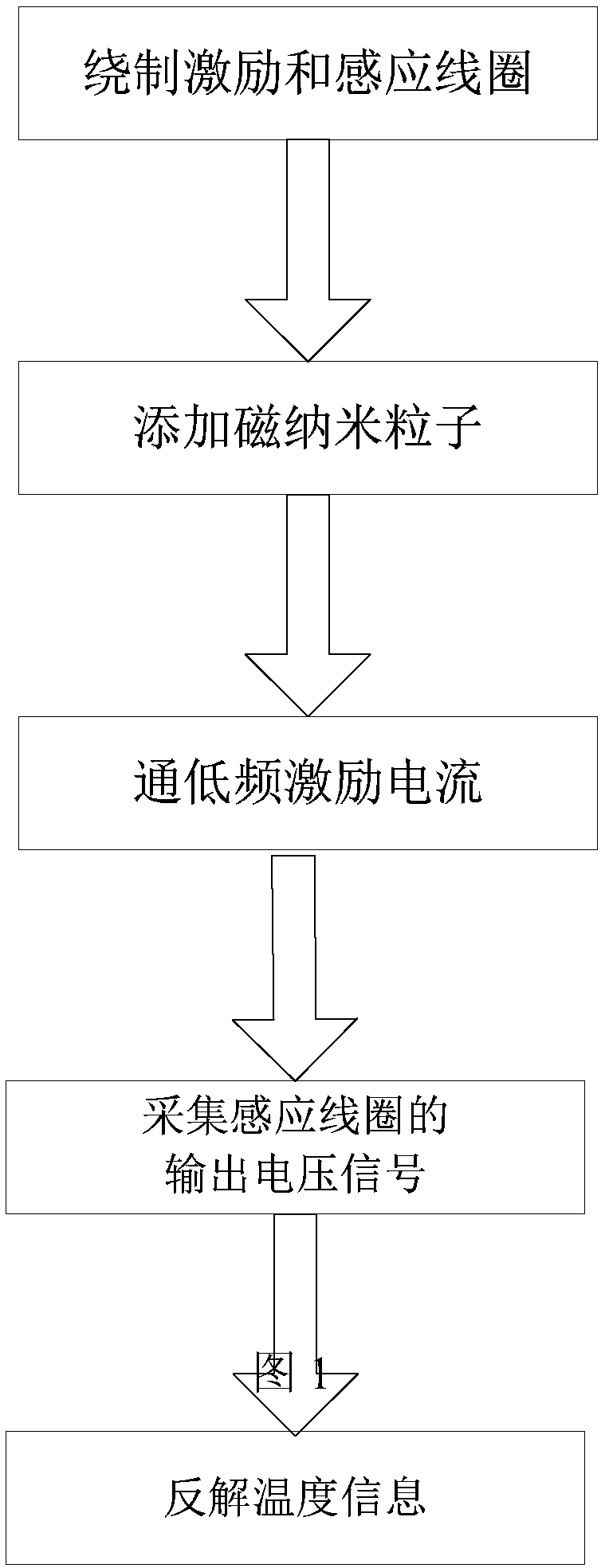

[0029] Such as figure 1 As shown, the present invention provides a magnetic nanoparticle inductive temperature measurement method that can be used for electromagnetic heating equipment, comprising the following steps:

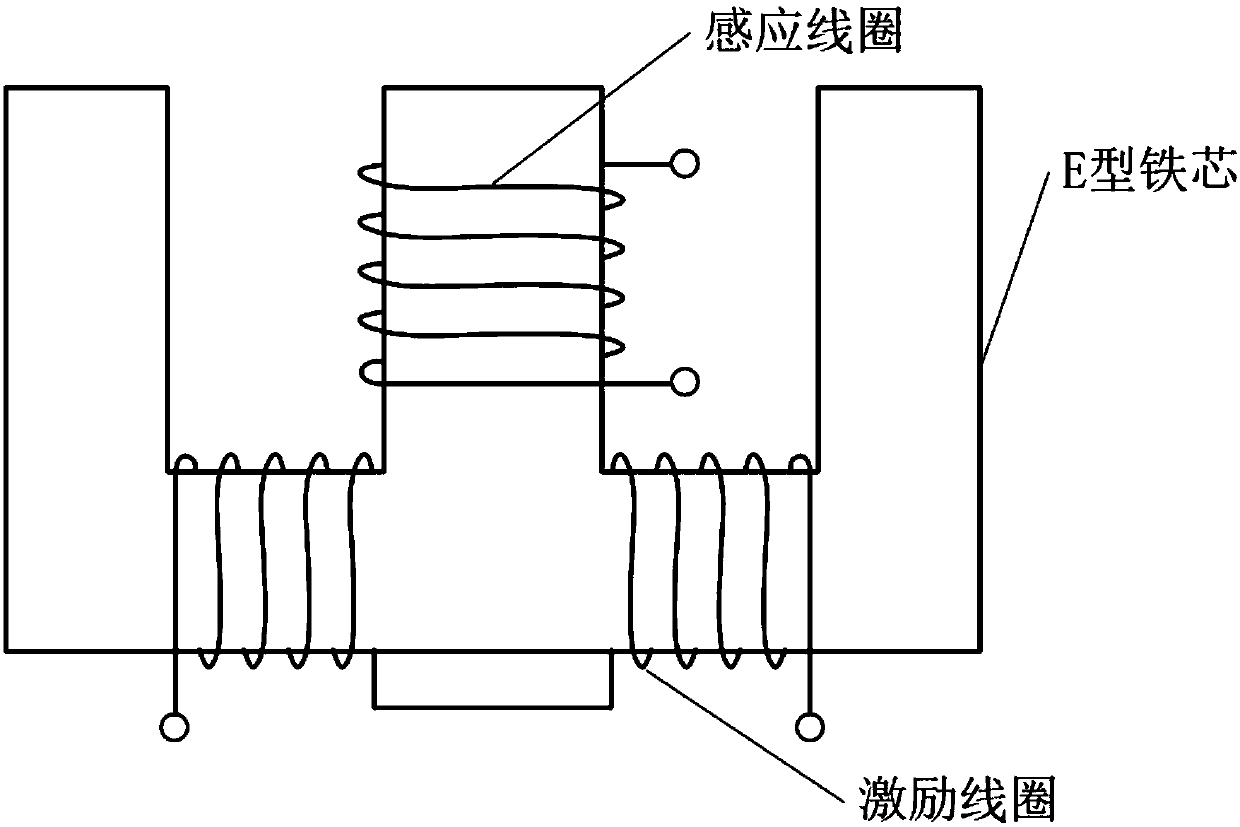

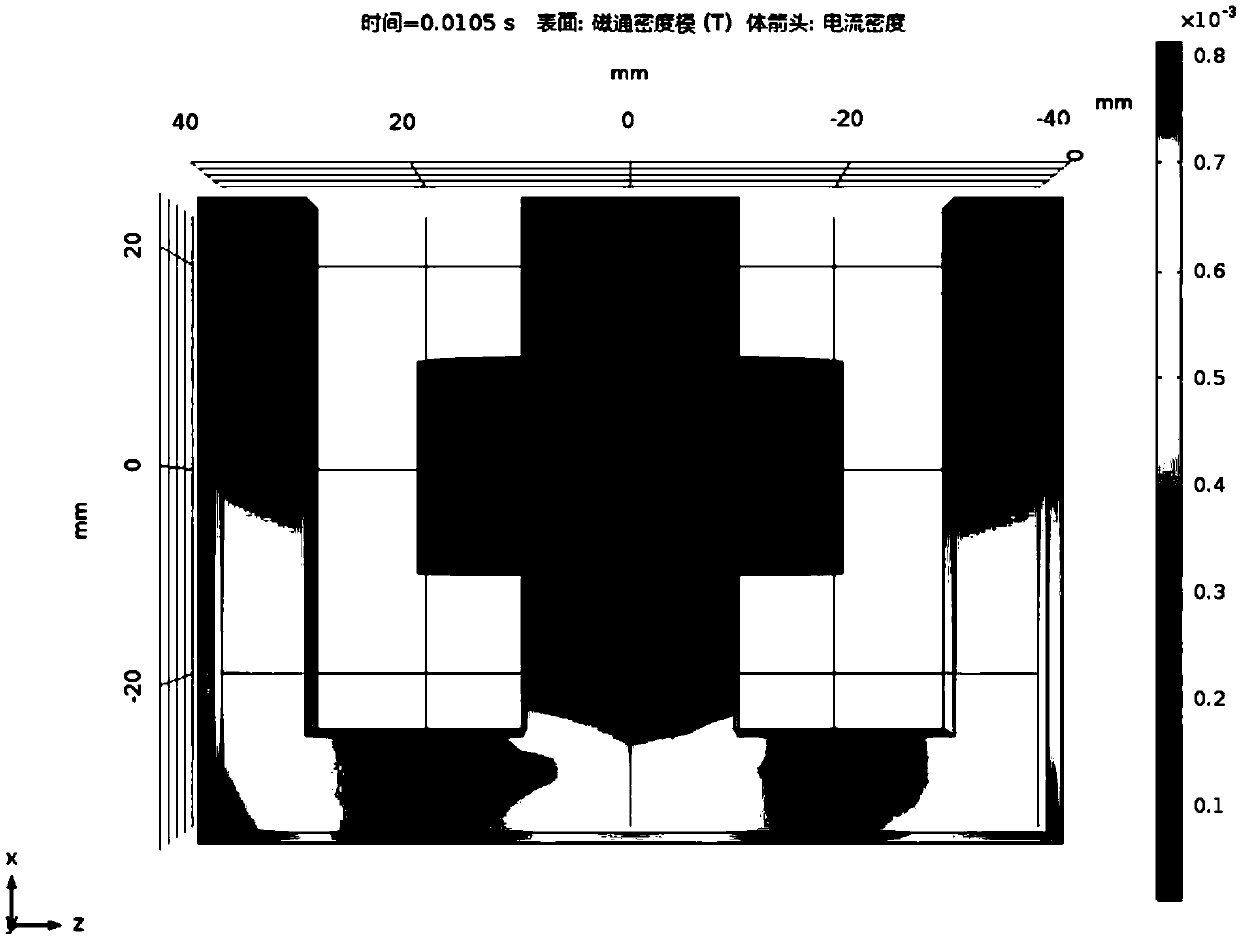

[0030] (1) Choose the most common such as E-type iron core to form a symmetrical structure. The sum of the sectional areas of the two side columns of the E-shaped iron core is equal to the sectional area of the central column. On the E-shaped iron core, the same direction excitation coil with the same position and symmetrical property is wound, and the coil inductance is L=μ o ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com