Counter-flame soot collection device and method and soot volume fraction measurement method

A collection device and volume fraction technology, applied in liquid/fluid solid measurement, measurement device, sampling device, etc., to avoid secondary experiment pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The lower nozzle of the opposing flame burner is fed with pure ethylene gas at a flow rate of 20cm / s, and the upper nozzle of the opposing flame is fed with a mixture of nitrogen and oxygen at a flow rate of 20cm / s, wherein the molar fraction of oxygen is 25%, and the molar fraction of nitrogen is 75% %, collect the soot under the above conditions and measure the soot volume fraction under the above conditions.

[0055] Follow the steps below:

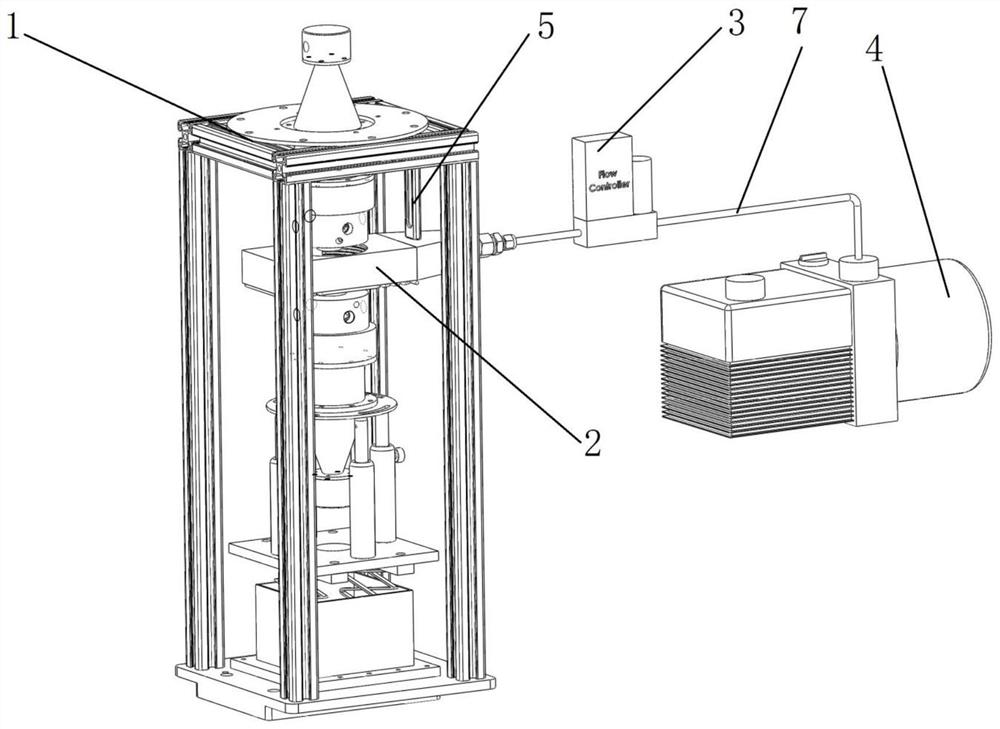

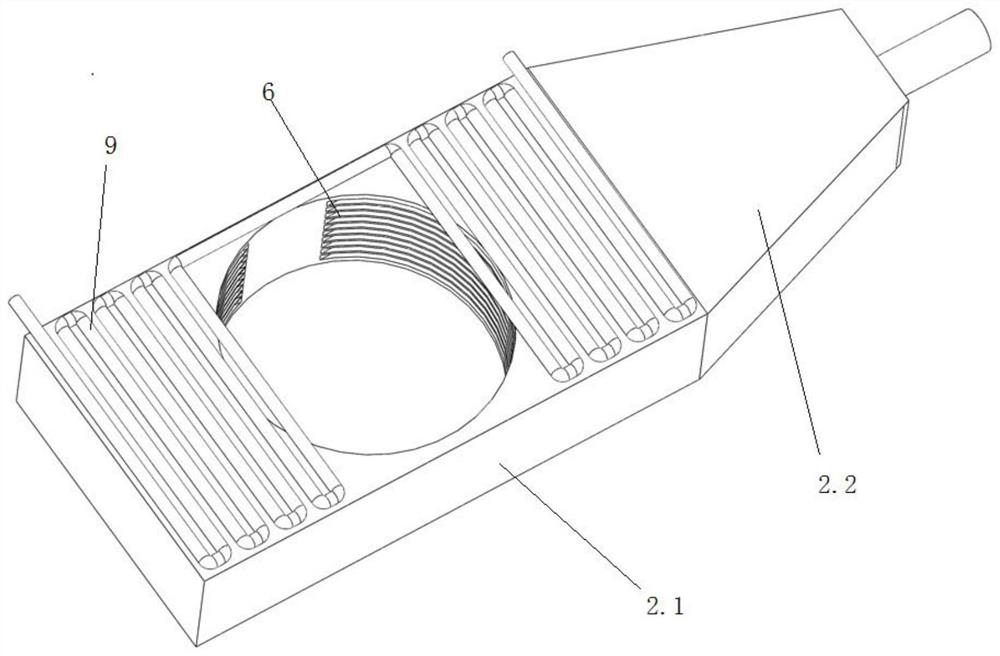

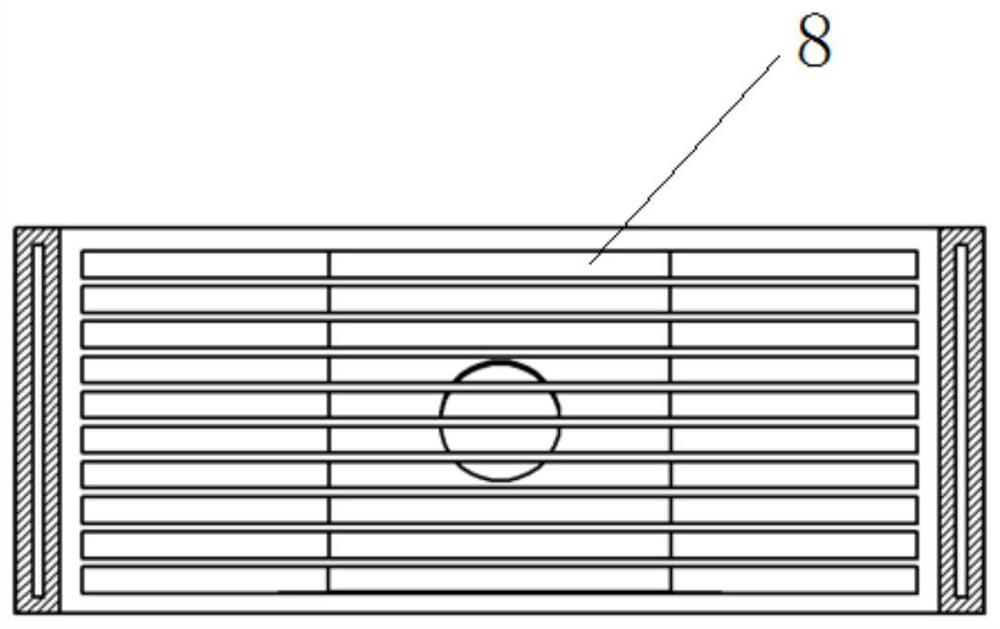

[0056] 1. Clean the collection probe 2 with acetone cleaning agent or absolute ethanol and distilled water, dry the collection probe 2, fix the polytetrafluoroethylene filter paper in the collection probe 2 with an adhesive, pass the collection probe 2 through The collection probe bracket 5 is connected to the opposite burner and its bracket 1, and the collection probe 2 is connected to the vacuum pump 4 through the pipeline 7;

[0057] 2. Select the fuel used by the opposite flame burner as ethylene gas;

[0058] 3. The lower...

Embodiment 2

[0069] The lower nozzle of the opposing flame burner feeds a mixed gas of ethylene and nitrogen at a flow rate of 20cm / s, wherein the molar fraction of ethylene is 28%, and the molar fraction of nitrogen is 72%. The upper nozzle of the opposing flame feeds a mixed gas of nitrogen and oxygen at a flow rate of 20cm / s, where the oxygen mole fraction is 90%, and the nitrogen mole fraction is 10%, collect the soot under the above conditions and measure the soot volume fraction under the above conditions.

[0070] Follow the steps below:

[0071] 1. Clean the collection probe 2 with acetone cleaning agent or absolute ethanol and distilled water, dry the collection probe 2, fix the polytetrafluoroethylene filter paper in the collection probe 2 with an adhesive, pass the collection probe 2 through The collection probe bracket 5 is connected to the opposite burner and its bracket 1, and the collection probe 2 is connected to the vacuum pump 4 through the pipeline 7;

[0072] 2. Selec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com