Double-station small-sized transformer tape winding machine and operation method

A technology for transformers and winding machines, which is applied in inductance/transformer/magnet manufacturing, coil manufacturing, electrical components, etc., can solve the problems of low operation efficiency, high labor intensity of operators, and inability to meet the needs of large-scale production. Labor intensity, improve winding efficiency, and ensure the effect of winding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

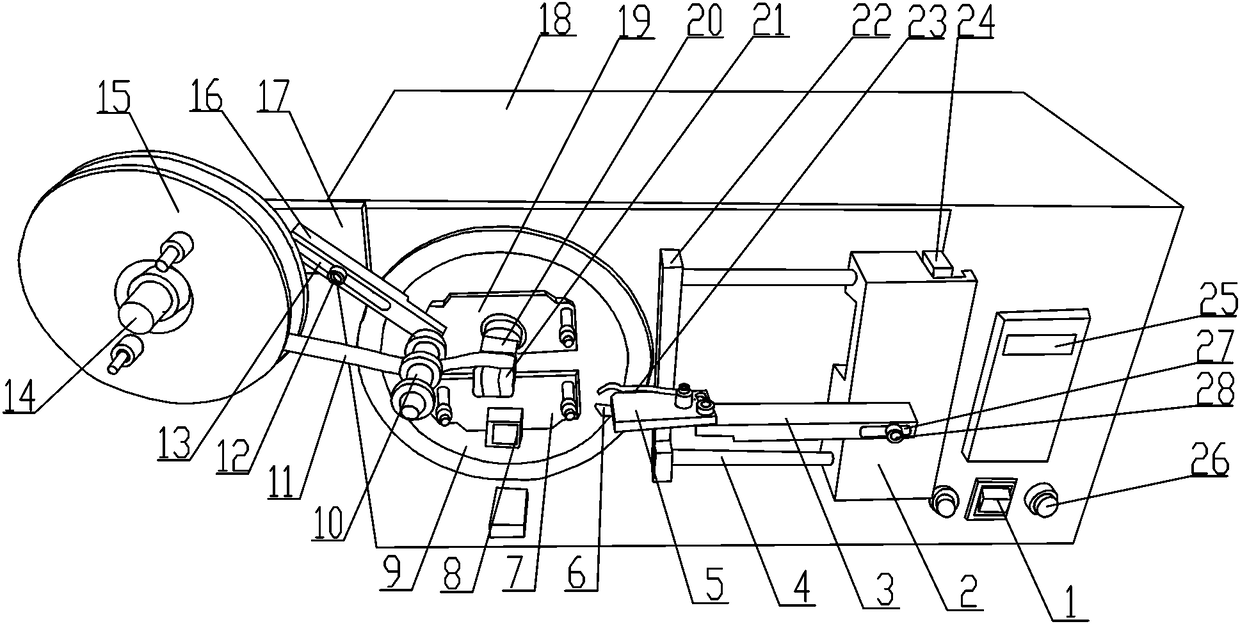

[0035] see figure 1 , a double-station small transformer tape winding machine, which includes a winding machine case 18, a rotating disc 9 is installed on the front end of the winding machine case 18, and the rotating disc 9 is connected to the main motor arranged inside the winding machine case 18; A first mounting base 19 and a second mounting base 7 are installed on the rotating disc 9, the first rotating shaft base 20 for installing a transformer is installed on the first mounting base 19, and the second mounting base 7 is installed for The second rotating shaft seat 8 of the transformer is installed; the top of one side of the rotating disk 9 is provided with a tape winding device for supplying tape; the other side of the rotating disk 9 is provided with a tape cutting device. The small transformer tape winding machine with the above structure can be used for tape winding of small transformers. It adopts a double-station structure and can alternately wind two transformers...

Embodiment 2

[0045] The operation method of any one of the double-station small-sized transformer tape winding machines, it comprises the following steps:

[0046] Step1: Install the tape storage reel 15 storing the tape 11 on the reel spindle 14;

[0047] Step2: install the first transformer that needs to be wrapped with tape on the first rotating shaft seat 20;

[0048] Step3: Wrap the end of the tape 11 on the outer wall of the transformer, and install the second transformer that needs to be wound on the second rotating shaft seat 8;

[0049] Step4: Start the first rotating shaft seat 20 to drive the transformer installed on it to rotate, and then wrap the adhesive tape 11 on the first transformer;

[0050] Step5: After the tape winding of the first transformer is finished, start the rotating disk 9, and drive the first mounting seat 19 and the second mounting seat 7 to rotate 90° through the rotating disk 9, and then turn the first rotating shaft seat 20 to tape cutting The position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com