Robotic method for automatic coating of insulating materials

An insulating material and automatic coating technology, which is applied in the direction of insulation/armored cable repair equipment, overhead line/cable equipment, etc., can solve the problems of affecting the efficiency of insulation construction, increasing construction cost, and long power outage time, so as to improve power supply Reliability, avoiding safety accidents, and solving hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Insulation coating of single-phase bare wires

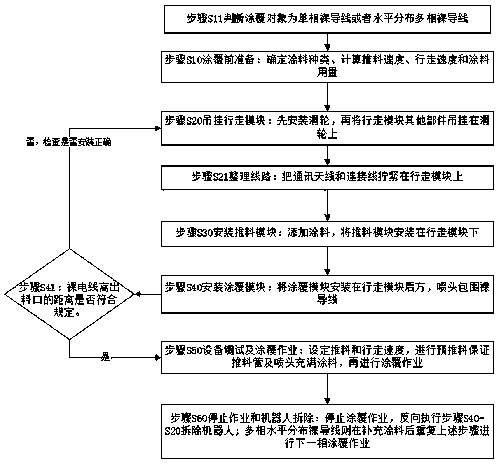

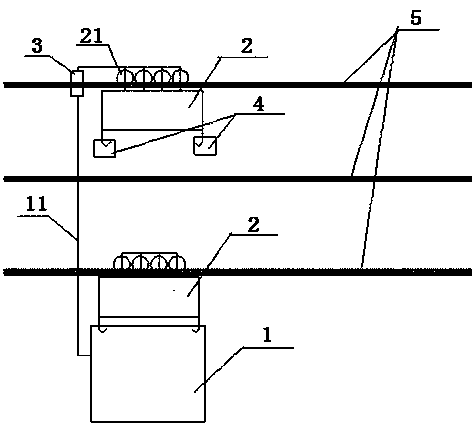

[0030] Such as figure 1 Shown is a method for automatic coating of insulating materials by a robot. The bare wire in this embodiment refers to a copper-cored aluminum stranded wire, which includes the following steps:

[0031] Step S10 Preparation before coating: According to the condition of the overhead bare wire, including the energized voltage of the bare wire, the wire diameter of the bare wire, and the thickness of the coating; According to factors such as the rotating speed per minute and the number of barrels extruded at the same time, select the appropriate paint and calculate the amount of paint, feeding speed and walking speed corresponding to the formula, and determine that the bare wire is a single-phase bare wire;

[0032] In this embodiment, the inner diameter of the barrel is d=125mm; the thickness of the paint is H=2mm; the height h=4mm that the push rod advances in one revolution; as follows:...

Embodiment 2

[0043] Example 2: Horizontal distribution of three-phase bare wire insulation coating

[0044] Compared with Embodiment 1, this embodiment differs in that the objects to be coated are three-phase bare wires distributed horizontally, and the three-phase bare wires are regarded as three single-phase bare wires respectively during the coating operation, according to The steps of the method described in Example 1 were repeated three times, and each time only a single phase was coated. After completing one of the phase coating operations, it is necessary to add paint to the paint bucket or replace a new standard paint bucket before re-working on the bare wires of the next phase.

Embodiment 3

[0045] Example 3: Vertical distribution of three-phase bare wire insulation coating

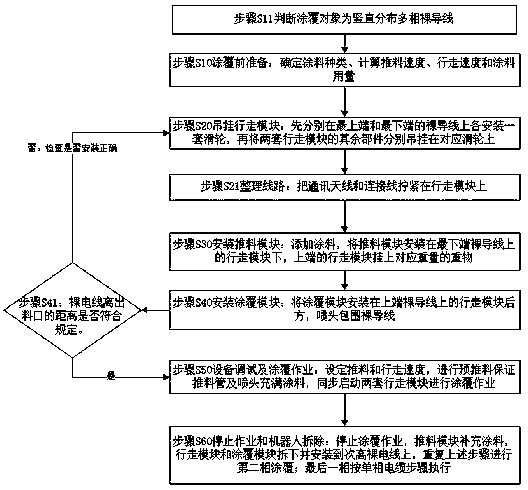

[0046] Compared with Embodiments 1 and 2, this embodiment differs in that the object to be coated is a vertically distributed three-phase bare wire, and the specific steps are as follows: figure 2 A method for automatic coating of insulating materials by a robot comprises the following steps:

[0047] Step S10 Preparation before coating: According to the condition of the overhead bare wire, including the energized voltage of the bare wire, the wire diameter of the bare wire, and the thickness of the coating; Based on factors such as the rotating speed per minute and the number of barrels extruded at the same time, select the appropriate paint and calculate the amount of paint, feeding speed and walking speed corresponding to the formula, and determine that the bare wire 5 is a single-phase bare wire 5.

[0048] In this embodiment, the inner diameter of the barrel is d=125mm; the thickness o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com